Commercial Stucco Testing: 7 Powerful Reasons to Avoid Costly Risks

Understanding the Critical Role of Commercial Stucco Testing

Commercial stucco testing is a specialized inspection process that evaluates the condition and integrity of stucco cladding systems on commercial buildings. Here’s what you need to know:

- Purpose: Identifies moisture intrusion, structural damage, and installation defects in stucco systems

- Types: Visual inspection, moisture testing, thermal imaging, and invasive probe testing

- Cost: $500-$3,500+ for commercial properties (varies by size and complexity)

- Frequency: Recommended every 2-4 years and before property transactions

- Benefits: Prevents costly repairs, protects property value, avoids litigation

Commercial buildings with stucco exteriors are significant investments that require proper maintenance and regular inspection. Unfortunately, research indicates that more than 90% of stucco applications in the Northeastern United States installed within the past 15 to 20 years contain improper installation details that can lead to moisture intrusion, structural damage, and costly repairs.

Unlike residential stucco, commercial stucco systems often cover larger areas, incorporate more complex architectural details, and may use different installation methods including traditional hard-coat stucco or synthetic EIFS (Exterior Insulation and Finish Systems). These differences demand specialized testing approaches from qualified professionals who understand commercial building envelope science.

Early detection through professional testing is crucial – moisture trapped behind stucco can silently damage structural components long before visible signs appear. A thorough commercial inspection combines visual assessment, moisture probe testing, and possibly infrared thermal imaging to create a comprehensive picture of your building’s condition.

My name is Gabe Kesslick, founder of Stucco Safe with over 20 years of experience in leak detection and commercial stucco testing across Pennsylvania, New Jersey, and Delaware. As an EDI Level 2 Certified Stucco Inspector and Building Envelope Forensic Inspector, I’ve helped thousands of property owners uncover and address hidden stucco issues before they become catastrophic failures.

Understanding Commercial Stucco Systems

Before we jump into testing methods, let’s take a moment to understand what we’re actually examining. Commercial buildings typically feature one of two main stucco systems, each with their own unique properties and potential weak spots.

Traditional Hard-Coat Stucco

Traditional stucco (or hard-coat stucco) has stood the test of time—literally centuries! This cement-based exterior cladding creates a robust, classic finish that many building owners prefer.

When you encounter traditional stucco, you’re looking at a layered system made of Portland cement, lime, and sand mixture applied over metal lath or wire mesh reinforcement. It typically features a three-coat application (scratch, brown, and finish coats) with a total thickness of about ⅞” to 1″.

The beauty of properly installed traditional stucco is its durability and fire resistance—it can protect your building for decades. However, it does have a porous nature, which means proper flashing, drainage, and water management systems are absolutely essential to prevent moisture problems down the road.

EIFS (Exterior Insulation and Finish Systems)

EIFS, often called synthetic stucco, burst onto the commercial building scene in the 1980s and 1990s. This multi-layered system offers a different approach to exterior cladding.

A typical EIFS installation includes foam insulation board (usually expanded polystyrene), a base coat with embedded reinforcing mesh, and a finish coat that’s acrylic or polymer-based. The whole system typically measures about 1″ to 4″ thick.

It’s worth noting that early EIFS systems were “barrier systems” with no built-in drainage—which unfortunately led to widespread moisture problems. Today’s modern drainage EIFS includes channels, drainage planes, or other clever mechanisms that allow water to escape if it penetrates the system.

| Feature | Traditional Hard-Coat Stucco | EIFS |

|---|---|---|

| Composition | Cement, lime, sand, water | Foam insulation, polymer base coat, acrylic finish |

| Installation | Applied over metal lath | Adhesively or mechanically attached |

| Sound | Solid tone when knocked | Hollow sound when knocked |

| Weight | Heavy (8-10 lbs/sq.ft) | Light (1-2 lbs/sq.ft) |

| R-Value | Low (R-0.2 per inch) | High (R-4 to R-5.6 per inch) |

| Drainage | Requires separate drainage plane | Modern systems include integrated drainage |

| Governing Standard | ASTM C926 (application), ASTM C1063 (lath) | ASTM C1397, ASTM C1481 |

Why Know Your System Before Testing?

Identifying which stucco system adorns your commercial building isn’t just about satisfying curiosity—it’s crucial for effective testing. Here’s why:

Different systems fail differently. Traditional stucco typically cracks and allows water to enter, while EIFS might trap moisture without showing any visible signs on the surface. Knowing your system helps us anticipate where problems might lurk.

The simple “knock test” can help identify your system in the field—traditional stucco produces a solid tone, while EIFS sounds hollow when knocked. This quick assessment gives us important clues about what we’re dealing with.

Buildings constructed between 1993 and 2006 have a significantly higher stucco failure rate—as high as 90%—due to incorrect building codes during that period. If your building dates from this era, it deserves extra attention.

Installation details matter tremendously. Traditional stucco requires proper control joints every 144-324 square feet to accommodate thermal expansion, while EIFS has different expansion requirements. The “7-inch fastener rule” for traditional stucco is another critical detail often overlooked during installation.

Visual clues like projections around doors and windows can reveal underlying construction methods that help identify the system and potential vulnerabilities. An experienced inspector knows exactly what to look for.

Understanding your specific stucco system allows our inspectors at Stucco Safe to zero in on the most likely failure points and select the most appropriate commercial stucco testing methods for your unique building. This targeted approach saves time, money, and prevents unnecessary damage during the inspection process.

Why and When to Schedule Commercial Stucco Testing

Commercial stucco testing isn’t just another maintenance task to check off your list—it’s a crucial risk management strategy that protects your investment. With alarming statistics showing that up to 90% of stucco installations in the Northeast contain significant defects, regular testing has become essential, not optional.

The High Stakes of Stucco Failure

When stucco problems go undetected, the consequences extend far beyond cosmetic concerns. Moisture trapped behind stucco can silently rot wooden framing members and corrode metal components for years before you notice any visible signs. This hidden damage creates perfect breeding grounds for toxic mold that threatens the health of everyone in your building.

The financial implications are equally serious. Property owners may face expensive lawsuits from tenants or buyers if undisclosed stucco issues cause damages. Many insurance companies have become increasingly cautious about stucco, with some requiring inspections or excluding stucco-related damage from coverage altogether. Perhaps most concerning for owners and investors, buildings with documented stucco problems can lose significant market value overnight.

Benefits of Regular Inspections for Owners & Managers

Smart property owners implement regular commercial stucco testing programs because they understand the substantial benefits. Early detection of minor issues prevents them from developing into major structural nightmares down the road, significantly extending your building’s lifespan and protecting your investment.

When it comes time to sell, properties with proper stucco certification move much faster. Having a MoistureFree Warranty can reduce time on market by as much as 50%—a compelling advantage in competitive real estate markets. These warranties typically require regular inspections to maintain coverage, creating another reason to stay on top of testing.

From a financial planning perspective, knowing the exact condition of your stucco system allows for predictable maintenance budgeting. Instead of facing surprise emergency remediation costs that can derail your annual budget, you can plan for needed repairs over time. Regular inspections also demonstrate your commitment to safety compliance, helping meet building code requirements and showing due diligence in property management.

When to Schedule Commercial Stucco Testing

At Stucco Safe, we recommend scheduling commercial stucco testing at these key times:

- Every 2-4 years as preventative maintenance

- Before purchasing any commercial property with stucco exteriors

- Prior to listing your property to avoid surprises during buyer inspections

- Following severe weather events like hurricanes or sustained heavy rains

- During renovations that impact the building envelope

- When tenant complaints arise about leaks, musty odors, or interior staining

- For buildings over 10 years old, especially without prior testing documentation

- When requested by lenders or insurers for refinancing or policy renewal

If you’re located in the Philadelphia area, our specialized Commercial Stucco Inspection in Philadelphia, PA service addresses the unique challenges of historic and modern commercial buildings in the region.

Key Triggers That Demand Immediate Testing

Some warning signs should prompt immediate action rather than waiting for your next scheduled inspection. Visible cracking or bulging, especially if cracks are wider than 1/16 inch or form distinct patterns, often indicates structural movement that needs addressing. Dark staining or discoloration on stucco surfaces typically signals water intrusion and possible mold growth behind the surface.

Pay close attention to missing or damaged flashing around windows, doors, and roof transitions—these are primary entry points for water. Any recent building envelope modifications like new signage installations or utility penetrations create potential leak points. Inside your building, water stains on ceilings or walls, musty odors, or visible mold should trigger immediate testing.

Stucco is often the last component to show visible failure signs. By the time you notice exterior damage, significant hidden problems may already exist behind the surface. The peace of mind that comes from professional testing is well worth the investment, with stucco inspections typically ranging from $495 to $1595 or more depending on building size.

Don’t wait until small problems become major headaches. Proactive commercial stucco testing protects your property value, prevents costly repairs, and ensures the safety of your building’s occupants.

The Commercial Stucco Testing Process

When it comes to commercial stucco testing, we believe in leaving no stone unturned. At Stucco Safe, we’ve developed a thorough, methodical approach that combines visual expertise with advanced diagnostic tools to give you the complete picture of your building’s condition.

The Step-by-Step Testing Workflow

Our process begins with a conversation. We’ll sit down with you to review your building’s history, discuss any previous repairs, and listen to your specific concerns. This context is invaluable—knowing where water stains appeared or which areas have been problematic helps us target our investigation.

Next comes our comprehensive visual inspection. Our certified inspectors examine every inch of your stucco surfaces, carefully documenting visible defects, cracks, bulges, and staining. We pay special attention to critical transition points where problems often begin—around windows, doors, control joints, and where different materials meet.

The real detective work starts with surface moisture mapping. Using specialized electronic scanners, we create detailed moisture gradient maps of your building’s exterior. Think of this as your building’s “weather map”—showing us exactly where moisture might be lurking beneath the surface.

Based on our findings, we then perform strategic invasive testing—drilling tiny 3/16″ holes at critical locations to measure the actual moisture content in your wall system. Don’t worry—we carefully seal these small test points with color-matched waterproof sealant that’s virtually invisible once we’re done. This step is crucial, as it tells us not just if there’s moisture, but exactly how much and where it’s affecting your structure.

When necessary, we supplement with additional testing methods. This might include infrared thermal imaging to identify temperature differences that could indicate moisture, substrate firmness testing to check the integrity of materials behind the stucco, or even adhesion testing following strict ASTM C1860 standards.

Finally, we compile everything into a comprehensive, easy-to-understand report. You’ll receive detailed moisture readings, photographs documenting our findings, clear analysis of what it all means, and prioritized recommendations for any necessary repairs.

Visual vs Invasive Commercial Stucco Testing

Many building owners ask about the difference between visual and invasive testing—and which is better. The truth is, they serve different purposes.

Visual inspection is our starting point—it’s non-destructive, covers all visible surfaces, and helps identify obvious defects. A trained eye can spot telling signs like improper flashing, missing kickout diverters, or suspicious crack patterns. However, visual inspection alone misses roughly 60-70% of significant moisture problems. By the time stucco shows visible damage, the problems behind it are often extensive and expensive.

That’s why we strongly recommend invasive testing as part of thorough commercial stucco testing. By taking actual moisture measurements at strategic points, we can detect problems long before they become visible—when they’re still relatively simple and affordable to fix. Yes, it creates small test holes, but these are easily sealed and virtually disappear. The peace of mind and potential savings are well worth it.

As one of our clients once put it: “Visual inspection is like checking if your roof leaks by looking at it from the street. Invasive testing is like actually going up there during a rainstorm.”

Tools & Technologies Deployed

Professional commercial stucco testing requires professional-grade equipment—and we invest in the best. Our inspectors use Extech moisture meters that measure from 1% to 100% moisture content, far exceeding the limited 1-40 scale of consumer-grade meters found at hardware stores.

We complement these with specialized hammer probes that let us measure moisture deep in wall cavities and structural components. For broader scanning, our surface moisture detection tools help identify problem areas that might need closer examination.

While many companies tout thermal imaging as a miracle solution, we take a more measured approach. Infrared cameras can be helpful in certain circumstances, but they have significant limitations with stucco. As one building scientist colorfully put it, “using thermal imaging for stucco is like having a screen door on a submarine”—they simply can’t reliably detect moisture in most stucco applications.

For structural assessment, we use specialized pull-off testers that measure stucco adhesion according to ASTM C1860 standards and substrate resistance probes that check the integrity of materials behind the stucco. When necessary, we can even deploy borescopes—tiny cameras that give us a direct view inside wall cavities without major disruption.

All this technology serves one purpose: giving you accurate, actionable information about your building’s condition so you can make informed decisions about its care and maintenance.

What to Expect From a Professional Inspection Report

When you invest in commercial stucco testing, you deserve more than just a pass/fail verdict. A professional report should tell the complete story of your building’s condition in clear, actionable terms. At Stucco Safe, we pride ourselves on delivering comprehensive reports that serve as both current assessments and valuable reference documents for years to come.

Essential Components of a Quality Report

Your inspection report begins with an executive summary that cuts to the chase – the overall condition of your stucco, major concerns we’ve identified, and our recommended next steps with clear urgency classifications. This allows busy property managers to quickly grasp the situation without wading through technical details.

Beyond the summary, we provide complete building information including your property details, the specific stucco system identified, construction history when available, and documentation of previous repairs. This context is crucial for understanding your building’s unique challenges.

We also thoroughly document our methodology, explaining which testing protocols we followed, the equipment used (including calibration status), and any industry standards referenced. If certain areas couldn’t be accessed or tested, we clearly note these limitations so you understand the complete picture.

The heart of our report includes detailed visual inspection findings organized by elevation, with photographs documenting every concerning detail. You’ll see our assessment of installation details, control joint placement, and other critical components that affect your stucco’s performance.

Perhaps most valuable are our moisture testing results, presented as color-coded moisture maps for each elevation. These intuitive visuals show exactly where moisture issues exist, with detailed readings from each test point compared against acceptable thresholds. This makes it easy to prioritize areas needing attention.

If we performed supplementary testing like infrared imaging, substrate firmness testing, or pull-off adhesion tests, these results are clearly explained with their implications for your building’s health.

We conclude with prioritized recommendations that help you plan repairs efficiently. Rather than leaving you with a laundry list of problems, we rank issues by urgency and provide suggested maintenance protocols, a recommended re-testing schedule, and warranty considerations.

Interpreting Moisture Readings

Understanding the numbers in your report shouldn’t require an engineering degree. We make moisture readings easy to understand with these guidelines:

Wood moisture content below 15% is generally considered acceptable and appears in green on our reports. Content between 16-19% shows in yellow, indicating liftd moisture that requires monitoring but isn’t immediately threatening. Readings between 20-28% appear in orange, signaling high moisture levels and active water intrusion that needs addressing. Anything above 28% shows in red, indicating severe conditions likely causing decay and requiring immediate attention.

Our color-coding system makes it simple to scan the report and immediately identify problem areas, even if you’re not familiar with moisture testing standards.

Credentials & Standards for Inspectors

The value of commercial stucco testing depends entirely on who’s doing the testing. When you work with Stucco Safe, you’re getting inspectors with industry-leading credentials including EDI Level II Stucco Inspector certification, Building Envelope Forensic Inspector training, and Moisture Warranty Corporation Certification.

Our inspectors follow established industry standards including ASTM C1780 for stucco installation, ASTM C1063 for lathing and furring, ASTM C1860 for tensile strength testing, and AWCI Technical Manual 12-B for EIFS inspection. We maintain current certifications and regularly update our methods to align with the latest industry developments.

You wouldn’t trust your health to an uncertified doctor – why trust your valuable property to uncertified inspectors? When reviewing potential inspection companies, always ask about their specific credentials and which industry standards they follow. The difference in report quality and accuracy can be dramatic.

For a better understanding of what to look for during an inspection, you might find our Printable Home Inspection Checklist PDF helpful, and property owners interested in specialized expertise should explore our Certified EIFS Inspector credentials.

Costs, Warranties, and Next Steps After Testing

When it comes to protecting your commercial property investment, understanding the financial aspects of commercial stucco testing helps you make smart, informed decisions that pay off in the long run.

Cost Factors for Commercial Stucco Testing

“How much will this cost me?” It’s often the first question property owners ask—and for good reason. Professional stucco inspection for commercial properties typically ranges from $500 to $3,500 or more, depending on several key factors.

At Stucco Safe, our standard inspections range from $495 to $1,595, with custom pricing for larger commercial properties. Why the range? Every building tells its own story:

A single-story strip mall with easy access requires fewer resources than a six-story office building with limited accessibility. Building height often significantly impacts cost, as multi-story structures may require lifts or scaffolding for proper inspection. Similarly, the complexity of your stucco system—whether you have multiple types or intricate architectural details—affects both inspection time and expertise needed.

The scope of testing also plays a major role in pricing. A visual-only assessment costs less than comprehensive invasive testing, but provides less definitive information. Think of it as the difference between a quick check-up and a thorough physical—both have their place, but they deliver different levels of certainty.

The Value of MoistureFree Warranty Protection

After completing your commercial stucco testing, many property owners find tremendous value in securing a MoistureFree Warranty. Think of it as insurance specifically for your building envelope.

These warranties offer coverage options from $10,000 up to $150,000, with terms of 1, 3, or 5 years available. One of the most valuable features is transferability—the warranty can follow the property to new owners, significantly enhancing your property’s marketability. In fact, properties with these warranties typically sell up to 50% faster than those without.

To qualify for this protection, your property must pass a certified stucco inspection performed by an authorized inspector like our team at Stucco Safe. The peace of mind this provides—knowing your building is protected against unexpected moisture issues—is often worth far more than the warranty’s cost.

From Findings to Fixes: Working With Contractors

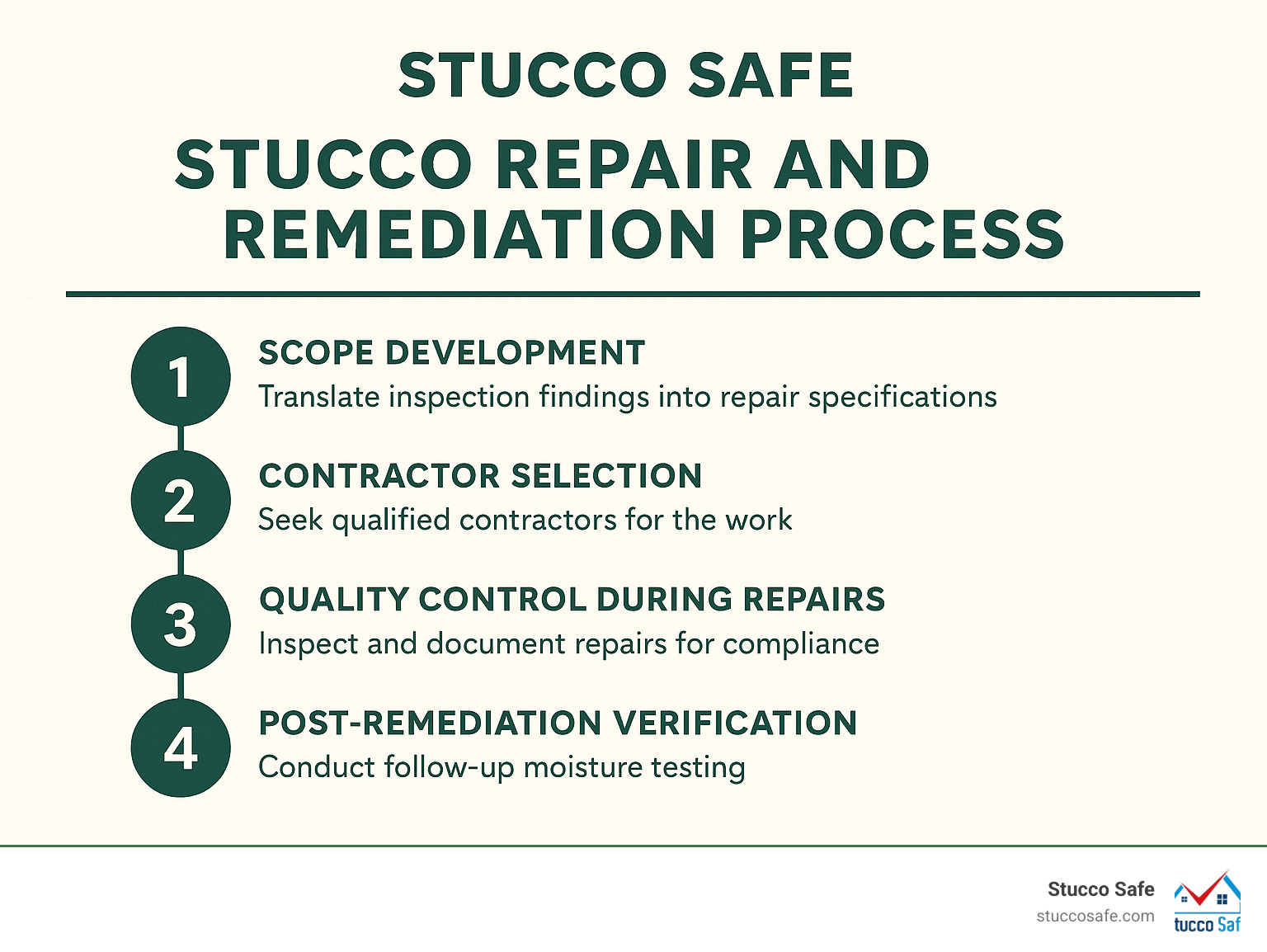

When your commercial stucco testing reveals issues needing remediation, navigating the repair process becomes crucial. This is where our expertise continues to serve you.

First, we help translate technical inspection findings into detailed repair specifications that contractors can bid on. We’ll prioritize repairs based on severity and risk, helping you develop a phased approach if budget constraints exist. This prevents contractors from simply giving you a “replace it all” quote when targeted repairs might suffice.

Selecting the right contractor makes all the difference. Look for professionals with specific experience in commercial stucco remediation, proper licensing and insurance, and stucco-specific credentials. Always request references from similar commercial projects, and obtain multiple bids based on identical scope specifications to ensure you’re comparing apples to apples.

During repairs, quality control becomes paramount. Schedule inspections of opened wall areas before they’re closed up, verify proper flashing installation at critical junctures, and document all repairs with photographs. This documentation proves invaluable for warranty purposes and future property transactions.

Developing a Long-Term Stucco Management Plan

After your initial commercial stucco testing and necessary repairs, I always recommend implementing a comprehensive stucco management strategy. Think of it as preventive healthcare for your building.

Schedule regular inspections every 2-4 years depending on your building’s age and condition. Complement these with annual visual checks of critical details like sealants and flashings—these simple checks can catch small issues before they become expensive problems.

Develop an immediate response protocol so your team knows exactly what to do when they spot new leaks or damage. Maintain thorough documentation of all inspections, repairs, and modifications—this history becomes invaluable during property transactions and insurance claims.

Finally, plan your budget wisely by setting aside reserves for future stucco maintenance. This proactive approach prevents the financial shock of unexpected repairs and protects your property value over time.

The modest cost of regular commercial stucco testing is a fraction of what you’ll spend on major remediation if problems go undetected. As we like to say at Stucco Safe, “Test it now, or fix it later”—and fixing it later always costs substantially more.

Frequently Asked Questions about Commercial Stucco Testing

How often should commercial stucco be tested?

When it comes to protecting your commercial property investment, timing is everything. We recommend commercial stucco testing at least every four years for buildings in good condition. However, some properties need more frequent attention—every two years is best for:

Buildings that have celebrated their 10th birthday or beyond

Properties battling coastal salt air or regions where rain seems never-ending

Structures with a history of moisture problems (like that one spot that always seems damp)

Buildings constructed during the problematic 1993-2006 period (we call these our “high-risk” properties)

Don’t forget that significant life events for your building also warrant testing—before selling or buying, after that hurricane blew through town, or when your tenants start mentioning water stains on their office ceiling. These aren’t just arbitrary guidelines—they’re based on years of seeing what happens when testing gets postponed too long.

What problems are most commonly found during inspections?

After performing thousands of inspections, we’ve seen patterns emerge. The most frequent issues our commercial stucco testing reveals might surprise you:

Installation defects top our “greatest hits” list. These include missing or improperly installed flashings where building materials meet, kick-out diverters that were forgotten or installed incorrectly, stucco that reaches too close to the ground (we need 6-8 inches of clearance), and control joints that are either missing entirely or placed incorrectly.

Water finds the path of least resistance, and our testing frequently identifies moisture entry points around window and door frames, where walls meet the roof, at deck attachments, and through utility penetrations. Even hairline cracks can invite surprising amounts of water behind your stucco.

System failures represent the most serious findings. We often find stucco separating from the substrate, metal lath that’s rusting away, deteriorated water barriers that were supposed to be your building’s raincoat, and rotting wood beneath the surface. Sometimes we find efflorescence—those white mineral deposits that signal water has been traveling through your wall system.

Catching these issues early through regular commercial stucco testing can save tremendous headaches and expense down the road.

Does probe testing damage the stucco surface?

I hear this question almost daily, and it’s a valid concern. Nobody wants their building looking like Swiss cheese! Here’s the straight talk about invasive commercial stucco testing:

The probe holes we create are tiny—just 3/16″ in diameter, about the width of a pencil lead. We’re not randomly drilling, either. Each hole is strategically placed based on our visual assessment and moisture mapping. After gathering our data, we immediately seal each hole with color-matched waterproof sealant that’s virtually invisible from normal viewing distances.

Think of it like this: would you rather have a few pinprick-sized holes that are properly sealed, or extensive water damage requiring thousands in repairs? It’s similar to how doctors use a small needle for blood tests to prevent bigger health problems.

The minor cosmetic impact of proper testing is far outweighed by the value of knowing what’s happening behind your stucco. Relying solely on non-invasive methods is like trying to diagnose a heart condition without checking vital signs—you might miss critical issues until serious damage occurs.

What’s the difference between commercial and residential stucco testing?

While we apply the same forensic approach to all properties, commercial stucco testing differs from residential inspections in several important ways:

Commercial inspections typically cover much larger surface areas and more complex architectural features—think multi-story office buildings versus single-family homes. This often requires specialized equipment like lifts or scaffolding to access upper floors safely.

The stucco systems themselves may differ too. Commercial buildings frequently use specialized systems with performance requirements not typically found in residential construction. This demands a deeper knowledge base from your inspector.

Documentation for commercial properties is also more extensive. Reports include more detailed findings and specifications, often requiring compliance with different building codes and standards than residential structures.

Time commitment varies significantly as well. While a residential inspection might take a few hours, commercial properties can require several days depending on size and complexity. This is reflected in the pricing structure, which is customized for each commercial property rather than following standard residential rates.

At Stucco Safe, we adapt our commercial stucco testing approach to meet each property’s unique requirements while maintaining our commitment to thorough, forensic-level evaluation across Pennsylvania, New Jersey, and Delaware.

Conclusion

Commercial stucco testing isn’t just another item on your building maintenance checklist—it’s a crucial investment in protecting your valuable real estate assets. The sobering reality is that up to 90% of stucco installations throughout the Northeast contain defects that could lead to moisture intrusion and structural damage. This makes regular professional testing not just important, but essential.

Here at Stucco Safe, we bring more than 20 years of building envelope expertise to every commercial inspection we perform. Our team of certified inspectors uses forensic-level testing methods to uncover hidden moisture issues before they turn into catastrophic failures. This proactive approach has saved our clients thousands in potential repair costs while safeguarding their property values.

What makes our approach different? We combine detailed visual assessments by certified stucco experts with state-of-the-art moisture detection equipment. Our strategic invasive testing methods cause minimal cosmetic impact while providing maximum insight into your building’s condition. After testing, you’ll receive clear, actionable reporting with prioritized recommendations and warranty options to protect and improve your property value.

We’re proud to serve commercial property owners throughout Southeastern Pennsylvania, New Jersey, and Delaware. Our coverage area includes Philadelphia, West Chester, Cherry Hill, Camden, Trenton, and Wilmington. Having worked extensively throughout the region, our team understands the specific challenges that local climate conditions and building practices present for stucco systems.

Don’t wait until visible damage appears on your building’s exterior. By that point, the hidden damage is often extensive and exponentially more costly to repair. Schedule your professional commercial stucco testing today and gain the peace of mind that comes from truly understanding your building envelope’s condition.

Remember this crucial fact: when it comes to stucco, what you can’t see absolutely can hurt you. But with Stucco Safe’s professional testing services, you’ll have the information you need to protect your commercial property investment for years to come.

Ready to take the next step? Contact us today to schedule your Commercial Stucco Inspections or learn more about our testing services. Our friendly team is standing by, ready to help you understand your building’s stucco system and develop a strategy for long-term protection that fits your needs and budget.