Pin vs Pinless Moisture Meter: Ultimate Accurate 2025

Why Accurate Moisture Measurement is Non-Negotiable

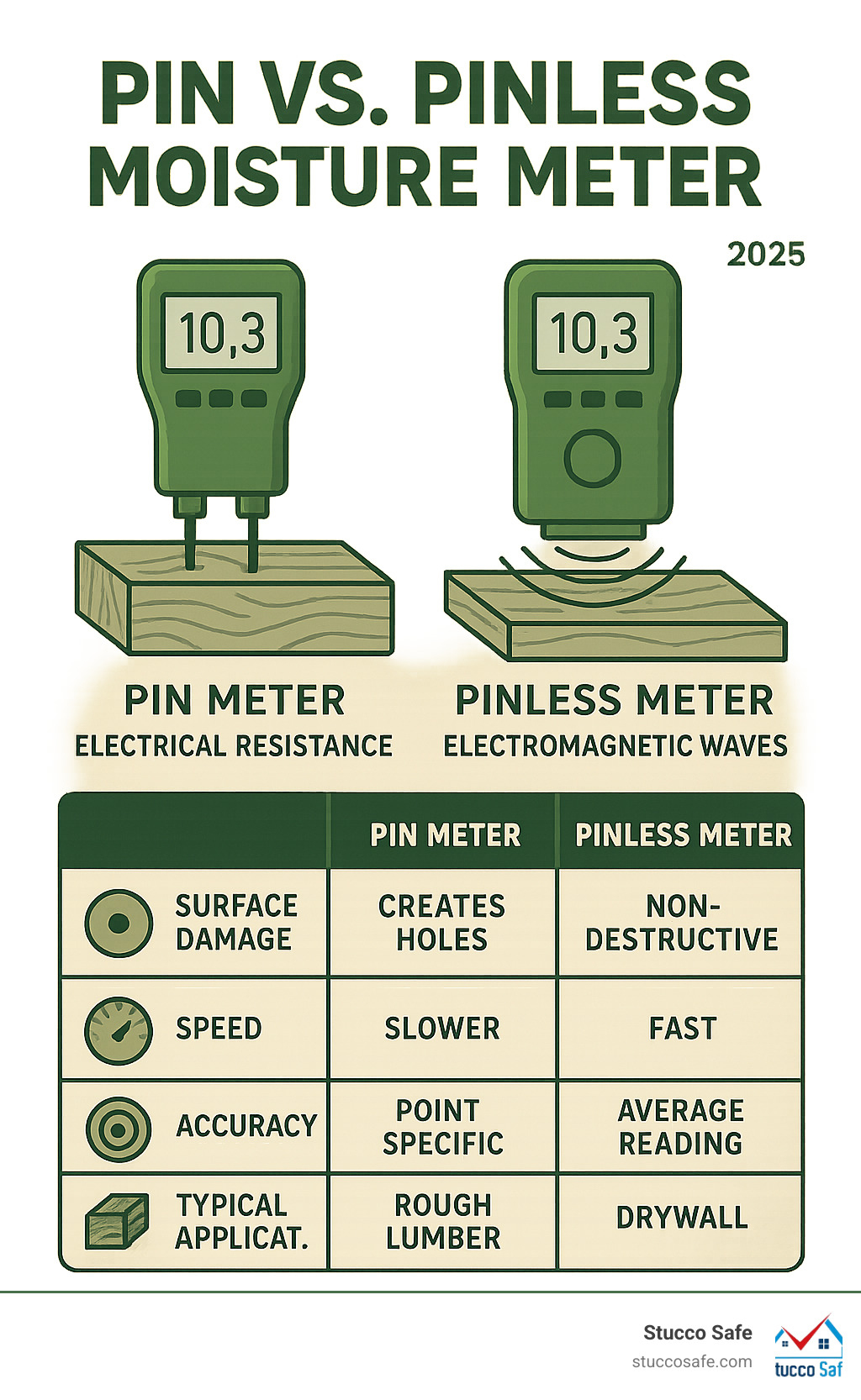

Understanding the difference between a pin vs pinless moisture meter can save you thousands in potential water damage repairs. Here’s a quick overview:

| Feature | Pin Meter | Pinless Meter |

|---|---|---|

| Surface Impact | Creates small holes | Non-destructive |

| Speed | Slower, multiple readings needed | Fast scanning of large areas |

| Best For | Uneven surfaces, rough lumber | Finished surfaces, drywall |

| Measurement | Point-specific at pin depth | Average reading of scanned area |

| Depth Control | Variable with different pin lengths | Fixed scanning depth (typically 3/4″) |

With water damage accounting for 24% of all property claims, accurate moisture detection is critical for protecting your home. Whether you’re checking wood moisture, investigating leaks, or dealing with stucco issues, the right meter can mean the difference between an early fix and costly repairs.

Pin meters use electrical resistance (via metal probes) to measure moisture, while pinless meters use non-penetrating electromagnetic waves. Each has distinct advantages depending on the material and accuracy needed.

I’m Gabe Kesslick, and I’ve been investigating building envelope failures since 2001. Through thousands of inspections, I’ve seen how choosing the right pin vs pinless moisture meter impacts the reliability of a moisture assessment.

How They Work: The Science Behind the Scan

Understanding how pin vs pinless moisture meter technologies work helps you choose the right tool. The fundamental difference is that pin meters make direct contact to measure moisture, while pinless meters scan from the surface without penetration.

The Pin-Type Meter: Measuring Electrical Resistance

Pin meters operate on a simple principle: water conducts electricity, while dry wood resists it. Inserting the two metal probes into a material creates an electrical circuit. The meter sends a current between the pins and measures the resistance. Higher moisture content leads to lower resistance, which the meter converts into a moisture percentage.

There are two types of pins. Non-insulated pins measure moisture along their entire length. Insulated pins are more precise, measuring only at their tips. This allows professionals to pinpoint moisture at specific depths by using different pin lengths or inserting them progressively deeper, creating a depth profile to map where moisture is hiding.

The Pinless Meter: Scanning with Electromagnetic Fields

Pinless meters use electromagnetic waves to scan beneath a surface without leaving marks. This is like having X-ray vision for moisture.

When placed on a surface, the sensor pad emits low-frequency waves, creating an electromagnetic field in the material. The meter detects changes in capacitance—how the field responds when it encounters moisture. Wet materials alter the field differently than dry ones, and the meter translates this change into a moisture reading.

This technology allows for rapid scanning of large areas. Most pinless meters measure the average moisture content within a fixed scanning depth, typically around 3/4 inch. You can see a video demonstration of pinless meters to appreciate their speed. While they lack the depth control of pin meters, they are excellent for quickly identifying potential problem areas.

The trade-off is clear: pinless meters offer speed and surface protection, while pin meters provide precision and depth control.

Pin vs. Pinless Moisture Meter: A Head-to-Head Comparison

Choosing between a pin vs pinless moisture meter requires understanding their strengths and limitations. Both have a place in a professional’s toolkit, but they excel in different situations.

| Feature | Pin Meter | Pinless Meter |

|---|---|---|

| Surface Damage | Yes (small holes) | No (non-destructive) |

| Speed | Slower (multiple readings needed) | Faster (quick scanning of large areas) |

| Best For | Uneven surfaces, rough lumber, loose-packed materials, specific depth readings | Flat, finished surfaces, quick area screening |

| Measurement Type | Point-specific (at pin depth) | Area average (of scanned volume) |

| Depth Control | Variable (with different pin lengths/insulated pins) | Fixed (typically 0.25″ to 1.5″ depending on model) |

| Material Sensitivity | Chemical composition, temperature, moisture gradient | Density (Specific Gravity), surface texture, presence of metal |

Surface Impact: Destructive vs. Non-Destructive

The most obvious difference is that pin meters leave small holes, while pinless meters are non-destructive. Pin meters create visible punctures, which are acceptable on rough lumber or materials that will be covered, but they are a major issue on finished surfaces like hardwood floors, painted walls, or custom millwork.

Pinless meters are completely non-invasive. They glide across surfaces without leaving a trace, making them the only choice for finished materials where aesthetics are a priority.

Speed and Efficiency

Pinless meters are built for speed. You can scan entire walls or floors in minutes, quickly identifying potential problem areas. This makes them ideal for initial investigations to get a big-picture view.

Pin meters are slower. Each reading requires carefully inserting the pins and waiting for a stable measurement. Checking a large area this way is time-consuming but provides highly specific data.

Measurement Depth and Distribution

This is where pin meters have a distinct advantage.

Pin meters offer precise depth control. Using insulated pins of varying lengths, you can create a moisture profile that shows exactly how deep a problem goes. This is critical for understanding moisture distribution, as detailed in guides on determining moisture distribution in a board.

Pinless meters have a fixed scanning depth, typically around 3/4 inch. They provide an average reading for that volume, which is great for general screening but doesn’t specify if moisture is on the surface or deep within. For thick materials, reading from both sides is recommended to get a more complete picture.

Application Guide: Choosing the Right Meter for the Job

There’s no universal “best” moisture meter. The right choice in the pin vs pinless moisture meter debate depends on the material, required precision, and whether the surface can be damaged. Matching the tool to the job is key.

When to Use a Pin Moisture Meter

Pin meters are the best choice for precision, especially when surface marks aren’t a concern.

- Uneven surfaces and rough lumber: Pinless meters struggle with inconsistent contact on rough-sawn lumber or weathered wood. Pins punch through to get a reliable reading.

- Loose-packed materials: Materials like insulation require compression against the pins for an accurate reading, which is impossible with a surface scanner. Direct contact is essential for testing loose-packed materials.

- Specific depth measurements: Insulated pins are invaluable for determining if moisture is just on the surface or has penetrated deep into a wall.

- Textured materials: Stucco, concrete block, and heavily textured drywall prevent good sensor contact for pinless meters, making pins more reliable.

When to Use a Pinless Moisture Meter

Pinless meters are ideal for speed and non-destructive testing.

- Finished surfaces: For hardwood floors, drywall, tile, and other expensive materials, a pinless meter is essential to avoid damage.

- Large area scanning: The ability to scan an entire room in minutes is the primary strength of pinless meters. This is perfect for testing large areas quickly.

- Quick screening: When you’re unsure where a moisture problem might be, a pinless meter lets you cast a wide net to find potential hot spots without leaving a mark.

The Professional Approach: Using Both Meters in Tandem

True professional moisture detection isn’t about choosing a pin vs pinless moisture meter; it’s about using both strategically.

- Initial Scan with Pinless: We start with a pinless meter to quickly scan large areas like walls and floors without causing damage, identifying potential hot spots.

- Confirm with Pin Meter: Once a suspicious area is found, we use a pin meter for precise readings. This confirms the presence of moisture and tells us exactly how much is there and how deep it goes.

This comprehensive, two-step assessment eliminates false positives and ensures accuracy. For example, a pinless meter might show a high reading near a window, but the pin meter can determine if it’s minor surface condensation or a serious leak into the wall cavity. This forensic approach is central to our stucco inspections, giving clients the detailed information they need.

Achieving Accurate Results: Best Practices and Common Pitfalls

Reliable readings from your pin vs pinless moisture meter depend on correct usage. Simple mistakes can lead to inaccurate results, causing users to miss serious problems or panic over false positives. Here’s how to ensure accuracy.

Calibration, Care, and Factors Affecting Readings

- Calibration: Your meter is a precision instrument. Check its calibration regularly using the manufacturer’s instructions, especially before a critical inspection or after a drop.

- Maintenance: Keep the meter clean. Wipe residue from pins and sensor pads, and store the device in a protective case to prevent damage from dust or falls.

- Environmental Factors: High humidity and extreme temperatures can affect readings. The ideal indoor humidity levels of 30-50% provide the best conditions for testing.

- Material Properties: Pin meters are affected by wood species’ chemical properties, while pinless meters are sensitive to density (specific gravity). Always use the correct species or density settings on your meter for accurate results.

- Surface Coatings: Most paints and lacquers don’t interfere with readings. However, coatings with metallic content can cause false high readings on pinless meters. Confirm suspicious readings with a pin meter.

Common Mistakes to Avoid with a pin vs pinless moisture meter

- Measuring on a Wet Surface: Surface moisture from rain or condensation will give falsely high readings. Always wipe the surface dry and wait at least 30 minutes before testing.

- Inconsistent Pressure (Pinless): Pinless meters require firm, consistent pressure. Gaps between the sensor and the surface will lead to unreliable readings.

- Ignoring Material Settings: Failing to adjust for wood species (pin) or density (pinless) is a common error that can significantly skew results.

- Misinterpreting Relative Readings: On non-wood materials like drywall, pinless meters give relative readings. Always establish a baseline from a known dry area to compare against.

- Metal Interference (Pinless): Measuring near nails, screws, or pipes can trigger false positives. Use a pin meter to verify high readings in areas where metal may be present.

- Damaged Pins: Bent or broken pins won’t make proper contact and will give unreliable readings. Inspect pins regularly and replace them when necessary.

Frequently Asked Questions about Moisture Meters

Here are answers to common questions about using moisture meters for your property.

Can a pinless meter accurately read moisture through stucco or drywall?

Yes, but with important limitations. For drywall, a pinless meter works well in a “relative mode.” You establish a baseline reading on a known dry area and then scan for significantly higher numbers, which indicate potential moisture without making holes.

For stucco, it’s more complex. The embedded wire lath can interfere with a pinless meter’s electromagnetic field, leading to inaccurate readings of the underlying material. For this reason, thermal cameras are also ineffective for stucco inspections.

For definitive moisture detection behind stucco, a pin meter is essential. At Stucco Safe, we use specialized probes inserted through small, discreet holes to get precise, forensic readings of the hidden wood framing and sheathing. This allows us to pinpoint issues a surface scan would miss.

How much do wood species, density, and coatings affect the readings of a pin vs pinless moisture meter?

These factors are critical for accuracy in the pin vs pinless moisture meter choice:

- Wood Species (Pin Meters): Different woods have different chemical compositions, affecting their electrical resistance. A pin meter must be set to the correct wood species to provide an accurate moisture percentage.

- Wood Density (Pinless Meters): Pinless meters are affected by material density (specific gravity). Denser woods interact with the electromagnetic field differently. High-quality pinless meters have settings to adjust for the density of various wood species.

- Surface Coatings: Most non-metallic coatings like paint or varnish do not significantly affect readings. However, coatings with metallic particles (e.g., some aluminum oxide finishes) can interfere with pinless meters, causing false high readings. If you suspect this, test a known dry, uncoated area first.

How do you ensure the accuracy and longevity of your moisture meter?

Proper care ensures your meter provides reliable results for years. Follow these best practices for your pin vs pinless moisture meter:

- Regular Calibration: Follow the manufacturer’s instructions to check calibration regularly, especially before critical inspections.

- Proper Storage: Keep the meter in its protective case to shield it from dust, moisture, and accidental drops.

- Keep it Clean: Regularly clean the pins or sensor pad with a dry cloth to prevent residue buildup from affecting readings.

- Avoid Extremes: Do not expose the meter to extreme temperatures or high humidity for long periods, as this can damage the electronics.

- Handle with Care: Avoid dropping the meter. When using a pin meter, don’t use excessive force that could bend or break the pins.

Conclusion: Making an Informed Decision for Reliable Results

The pin vs pinless moisture meter debate isn’t about finding a single winner. It’s about choosing the right tool for the job, which often means using both.

- Pin meters offer precision and depth-specific readings, ideal for rough surfaces and confirming exact moisture levels.

- Pinless meters provide speed and surface protection, perfect for scanning large, finished areas without causing damage.

For professionals, the most reliable approach is to use a pinless meter for a quick initial scan, then confirm hot spots with a pin meter for a precise diagnosis. This comprehensive method is crucial when dealing with hidden moisture that can cause thousands in damage.

While a DIY approach may work for simple tasks, complex issues like stucco problems require professional expertise. Stucco damage often hides beneath the surface, becoming a major issue before it’s visible. This is where forensic testing methods are invaluable.

At Stucco Safe, we have been investigating building failures since 2001 in Southeastern Pennsylvania, New Jersey, and Delaware. Our certified inspectors use both pin and pinless moisture meter technologies in our comprehensive testing protocols. We serve Philadelphia, West Chester, Villanova, King of Prussia, and throughout Chester County.

Stucco inspections range from $495 to $1595+, a small investment compared to remediation costs that can run into the tens of thousands. The peace of mind from knowing what’s behind your walls is priceless.

Don’t leave your property’s health to guesswork. For expert analysis with the right tools, get a certified moisture testing inspection and protect your investment.