Non Invasive Moisture Testing: Smart & Safe 2025

The Silent Threat Lurking in Your Walls

Non invasive moisture testing allows you to detect hidden water damage in your walls, ceilings, and floors without drilling holes or causing surface damage. Here’s what you need to know:

What is Non-Invasive Moisture Testing?

- Technology: Uses electrical impedance, capacitance, or radio frequency to scan surfaces.

- How it Works: Electromagnetic sensors detect moisture through finished surfaces like paint, drywall, tile, and stucco.

- No Damage: Leaves no probe holes or marks on your walls.

- Speed: Scans large areas in minutes versus hours with invasive methods.

- Use Cases: Ideal for initial inspections, post-flood monitoring, pre-purchase assessments, and detecting hidden leaks.

Behind a perfectly normal-looking wall, moisture could be quietly destroying your home’s structure and creating conditions for mold growth. Water intrusion doesn’t announce itself—it sneaks in through tiny cracks and works its destruction in silence. By the time you see visible signs, the damage has often spread far beyond the initial entry point.

Traditional moisture testing required drilling holes to insert probes, leaving behind damage and repair costs. This forced homeowners to choose between risking hidden moisture and accepting cosmetic damage.

Non-invasive moisture testing changed this entirely. These advanced tools use electromagnetic technology to detect moisture through your walls, tile, and flooring. No drilling, no probes, and no repair bills—just accurate readings that help you identify problem areas before they become disasters.

While the technology has limitations we’ll explore, it’s the gold standard for initial moisture investigations. Modern devices can penetrate up to 1¼ inches below the surface, providing immediate feedback on moisture levels.

I’m Gabe Kesslick, a BESI Level 2 Certified Building Envelope Forensic Inspector. Since 2001, I’ve used non invasive moisture testing in hundreds of building envelope investigations to help homeowners detect hidden water intrusion before it leads to costly structural repairs. I rely on these tools daily to provide clients with accurate assessments while preserving their property’s finished surfaces.

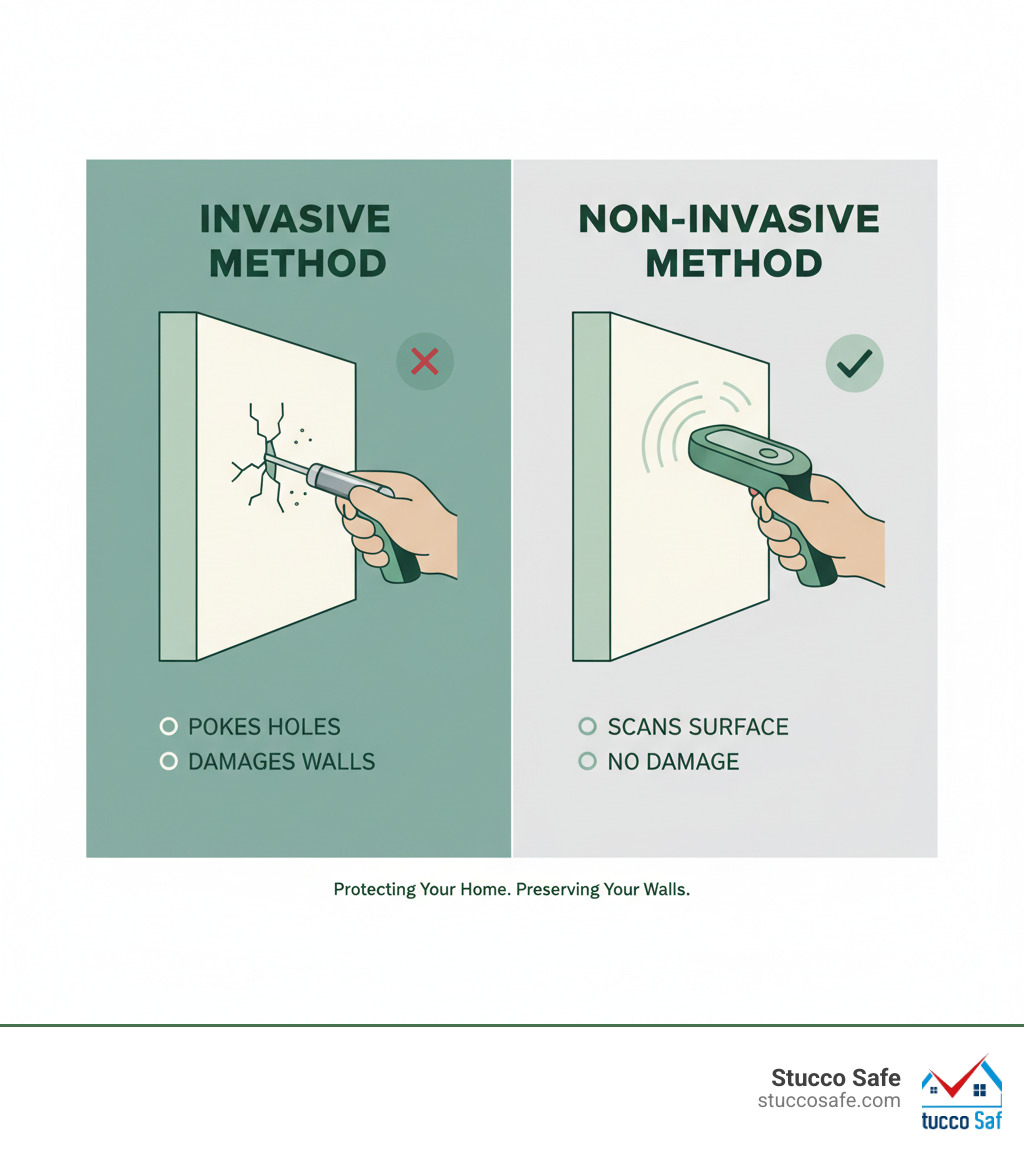

The Tale of Two Tests: Invasive vs. Non-Invasive Methods

When you suspect moisture, you have two investigation options: the “poke-and-prod” method (invasive) and the “scan-and-see” technique (non-invasive). Like a doctor’s exam, we start with the least intrusive method first. We begin with non invasive moisture testing to get a broad overview, then use invasive methods only when confirmation is needed. This approach protects your property while delivering the necessary information.

Here’s how these two approaches stack up:

| Feature | Invasive Moisture Testing | Non-Invasive Moisture Testing |

|---|---|---|

| Surface Damage | Requires drilling holes, removing cladding, or piercing surfaces. | No damage to the surface; preserves aesthetics. |

| Speed & Efficiency | Slower, as it involves physical alteration and repair. | Faster, allowing quick scanning of large areas. |

| Scope of Inspection | Provides precise, quantifiable readings at specific points. | Identifies general areas of liftd moisture over broad surfaces. |

| Accuracy | Highly accurate for quantifying moisture content at the point of penetration. | Provides comparative readings; can be influenced by material density or hidden objects. |

| Typical Use Case | Confirming moisture presence, quantifying exact levels, forensic analysis. | Initial surveys, pre-purchase inspections, monitoring drying, finding hidden leaks. |

What is Non-Invasive Moisture Testing?

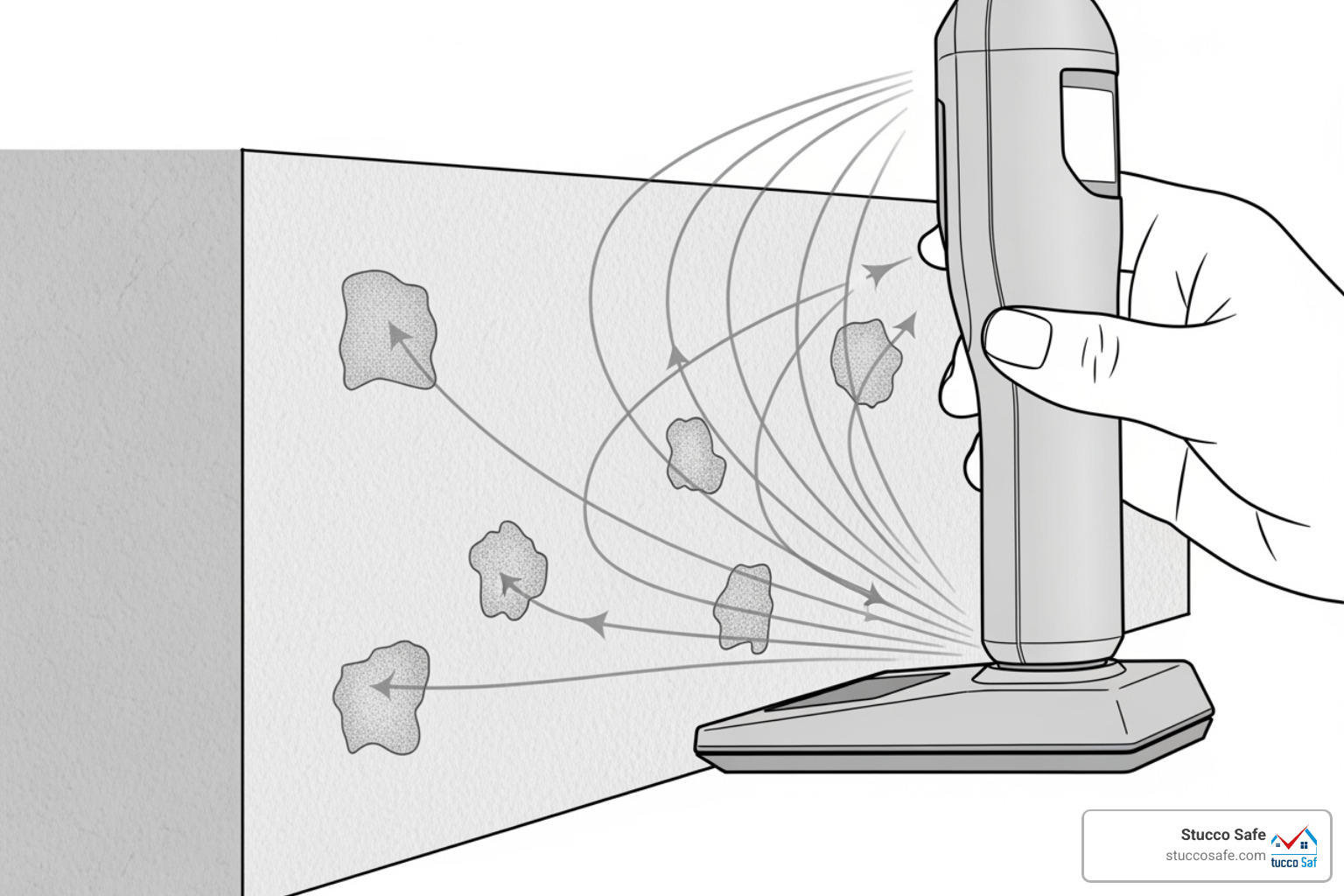

Non-invasive moisture testing examines your walls without breaking the skin. Instead of drilling, these meters use electrical impedance, capacitance, or radio frequency to detect what’s happening beneath the surface. The technology sends electromagnetic signals into the material. Water is highly conductive and affects these fields, allowing the meter to identify areas with liftd moisture.

This scanning approach is fast, allowing assessment of entire rooms in minutes. A wall might look fine, but the meter can reveal moisture hiding just below the paint or behind the drywall.

How Does It Differ from Invasive Testing?

The key difference is physical penetration. Invasive testing means breaking the surface—drilling holes for pin-type meters or removing cladding. These methods give highly accurate, quantifiable moisture percentages but cause property damage and repair costs.

In practice, non invasive moisture testing is the reconnaissance mission, flagging areas of concern. Invasive testing is the targeted follow-up, confirming the initial scan and providing exact measurements for decision-making. For example, if a non-invasive scan shows high readings on a stucco wall, we might recommend an invasive test to confirm the moisture content in the sheathing.

This two-step approach minimizes damage while maximizing information. It’s especially important for pre-purchase home inspections, where owners don’t want unnecessary holes drilled. Throughout Southeastern Pennsylvania, New Jersey, and Delaware, we use this balanced approach to give clients accurate assessments without damaging their homes.

The Science Behind the Scan: How Pinless Meters Work

Pinless moisture meters use electromagnetic science to see inside your walls. When pressed against a surface, the device emits an electromagnetic signal into the material. This signal is looking for one thing: water.

Water has a high dielectric constant, meaning it’s very good at storing electrical energy. When the meter’s signal encounters moisture, the water causes a measurable change in the electrical field. The meter detects these changes and translates them into a reading. Essentially, non invasive moisture testing reads the unique electromagnetic “fingerprint” of wet materials without breaking the surface. This technology allows us to scan an entire wall section in the time it takes to drill a single invasive test hole.

Capacitance and Radio Frequency Explained

The two main technologies in pinless meters are capacitance and radio frequency (RF). Both use water’s unique electrical properties.

-

Capacitance meters measure a material’s ability to store an electrical charge. When you measure capacitance, the meter’s sensor pads act as conductive plates and your wall is the insulator. Moisture dramatically increases the material’s ability to store a charge, which the meter detects.

-

Radio frequency meters emit radio waves and measure how they are absorbed or reflected. Water alters how the material interacts with these waves, allowing the meter to pinpoint moisture.

Both technologies are excellent for quickly surveying large areas and are ideal for initial inspections where we need to be efficient while preserving finished surfaces.

What Do the Readings Actually Mean?

This is where professional experience is critical. Most non-invasive meters display readings on a relative scale from 0 to 100. This is a comparative scale, not an absolute moisture percentage for all materials. A higher number means more moisture, but what’s considered “high” depends on the material being tested.

For wood, some advanced meters provide actual Wood Moisture Content (MC%) readings (5% to 30%), which is useful since wood above 20% MC is at risk for decay. For other materials like drywall or stucco, the reading remains on the comparative 0-100 scale.

In practice, we establish a baseline by taking a reading on a known dry area. We then scan for anomalies. A reading of 65 on drywall is a significant deviation if the dry baseline is 20, indicating moisture is present. It’s about pattern recognition and understanding the context.

This is why non invasive moisture testing requires skilled interpretation. Readings can be influenced by hidden metal studs or wiring. An inexperienced operator might misinterpret these signals. The meter is only as good as the person holding it, which is why our certified inspectors’ experience is so valuable.

Best Practices for Accurate Non-Invasive Moisture Testing

Getting reliable results from non invasive moisture testing requires proper technique. Following correct procedures separates accurate assessments from misleading readings.

Key best practices include:

- Calibration Checks: Before every inspection, we verify our meters against calibration standards to ensure accuracy.

- Surface Contact: The sensor pads must sit flush against the material. A tilted meter or a gap will produce incorrect readings. This requires firm, even pressure, especially on textured surfaces like stucco.

- Scanning Patterns: We scan in systematic, overlapping grids, working methodically around windows, doors, and baseboards to build a complete picture of moisture distribution.

- Environmental Factors: We account for temperature and humidity, which affect how materials hold moisture, to correctly interpret readings.

Choosing the Right Features for the Job

Not all meters are equal. We look for specific features to improve accuracy and functionality:

- Material Settings: A quality meter, like the Tramex ME5, is pre-calibrated for different materials (drywall, wood, concrete) and provides actual moisture content percentages (MC%) for wood.

- Adjustable Depth Penetration: Dual-depth capabilities (e.g., shallow up to ⅜ inch and deep up to 1¼ inches) help determine if moisture is on the surface or deep within a wall assembly.

- Digital Display: Provides precise numerical readings for detailed reporting and tracking.

- Audible Alerts: A practical feature that signals high moisture, allowing the inspector to focus on scanning.

- Data Hold Function: Freezes the reading, which is useful for taking measurements in awkward spaces.

- App Connectivity: Bluetooth allows us to create moisture maps, log data, and generate comprehensive reports on-site.

Common Scenarios for Non-Invasive Moisture Testing

The versatility of non invasive moisture testing makes it ideal for many situations:

- Stucco and EIFS Systems: We quickly scan large exteriors to find hot spots without leaving a mark, a core part of our work at Stucco Safe.

- Behind Ceramic Tile: We can check for shower leaks or problems behind backsplashes without removing any tile.

- Under Flooring: We scan for hidden moisture before new installation or to diagnose issues with existing hardwood or laminate.

- Flat Roofing: These meters excel at pinpointing moisture infiltration in roofing membranes.

- Post-Flood Drying: We can monitor the drying of walls and floors without causing more damage.

- Pre-Purchase Home Inspections: This technology is invaluable for revealing hidden problems without damaging a property you don’t yet own. Finding these issues before closing can save buyers thousands in unexpected repairs.

The Role of Modern Tech in Non-Invasive Moisture Testing

Technology has transformed non invasive moisture testing into a sophisticated diagnostic process.

Bluetooth connectivity is the biggest leap, allowing meters to communicate with mobile apps like the Tramex Meters App. This enables us to:

- Create Moisture Maps: We plot readings onto a digital floor plan or photo, creating a color-coded visual of moisture concentration.

- Generate Reports: We compile readings, photos, and notes into professional reports directly from the field.

- GeoTag Results: Each reading is tagged with GPS coordinates for precise location tracking.

- Log Data: We can track moisture levels over time to monitor drying progress.

This integration of hardware and software allows us to create a comprehensive forensic record of a property’s condition, aligning with Stucco Safe’s commitment to advanced testing methods.

The Pros and Cons: A Balanced View

Non invasive moisture testing is powerful, but it’s not a magic wand. The most accurate assessments come from understanding both its strengths and its weaknesses. It’s the first step in a conversation with your home, but sometimes that conversation reveals something that requires a deeper look with other methods. Knowing when to use each tool is key to getting accurate answers without unnecessary damage.

Key Advantages

The benefits of non invasive moisture testing make it our go-to first step:

- No Surface Damage: We scan walls, floors, and stucco exteriors, leaving no trace behind. This is invaluable for preserving finished surfaces like painted drywall, tile, and stucco facades.

- Speed and Efficiency: We can survey large areas in minutes, quickly identifying potential problem zones. This is especially useful during thorough pre-purchase inspections.

- Accessing Tight Spaces: Pinless meters can take readings in narrow gaps and corners where traditional probes can’t reach.

- Perfect for Finished Surfaces: The technology detects moisture through finished layers like paint, wallpaper, and tile without disturbing them.

These advantages make it an essential tool for protecting your property while respecting its condition.

Potential Limitations and Drawbacks

While we rely on this technology daily, we are also aware of its limitations:

- False Positives from Metal: Conductive materials like metal pipes, wiring, and studs can interfere with readings, creating false positives. Experienced inspectors learn to recognize these patterns and verify findings.

- Limited Depth Penetration: While advanced meters can penetrate up to 1¼ inches, moisture hiding deeper in a wall cavity might be missed on an initial scan.

- Material Density Variations: Different materials have different densities, which can affect readings. Professional meters have settings to compensate, but it’s a factor in interpretation.

- Requires Experienced Interpretation: The relative readings require a skilled operator to interpret them correctly, identify anomalies, and recognize when interference is causing false readings.

- Textured Surfaces: Achieving consistent sensor contact on heavily textured surfaces like some stucco can be challenging and may lead to inconsistent readings.

These limitations reinforce why a comprehensive inspection is vital. We combine surface scanning with visual assessment and, when necessary, targeted invasive testing to confirm our findings and provide a trustworthy assessment.

Conclusion: Gaining Insight Without Intrusion

You need answers about potential water damage, but you shouldn’t have to tear apart your walls to get them. Non invasive moisture testing offers a powerful solution, allowing you to detect hidden moisture quickly, accurately, and without leaving a mark.

As we’ve explored, these tools use electromagnetic fields to scan everything from stucco to tile, identifying problem areas in minutes. We’ve also been honest about their limitations, which is why professional interpretation is key.

For homeowners across Southeastern Pennsylvania, New Jersey, and Delaware, non invasive moisture testing is a smart first step in protecting your investment. It provides invaluable peace of mind by answering the crucial question: Is there a moisture problem here?

However, non-invasive scanning is just the beginning of a comprehensive evaluation, especially for complex systems like stucco. At Stucco Safe, we start with non-invasive testing and then go deeper. Our certified inspectors combine advanced scanning with forensic testing methods and years of experience to give you the complete picture. We determine if there’s moisture, where it’s coming from, and what to do about it. An investment in our expertise can save you thousands in future repairs.

Don’t wait for hidden moisture to become visible damage. Take the proactive step of a professional inspection to gain the insight you need without the intrusion you don’t.

Learn more about our professional non-invasive stucco inspection services.