Drill Bits: Ultimate Guide 2025

Understanding the Essential Tool for Every Project

Drill bits are cutting tools that attach to a power drill to create cylindrical holes. They come in dozens of types, each engineered for specific materials like wood, metal, or concrete.

Quick Reference: Main Types of Drill Bits

| Type | Best For | Key Feature |

|---|---|---|

| Twist Bits | Wood, metal, plastic | Most common, general purpose |

| Masonry Bits | Concrete, brick, stucco | Carbide tip for hard materials |

| Brad-Point Bits | Wood | Precise positioning, clean holes |

| Spade Bits | Wood | Large diameter holes |

| Tile & Glass Bits | Ceramic, glass | Spear-shaped tip prevents cracking |

| Step Bits | Sheet metal | Multiple hole sizes in one bit |

Choosing the right drill bit is the difference between a clean, professional result and a damaged surface. The global drill bits market reached $7.8 billion in 2022, with twist drill bits accounting for over 50% of all bits sold. High-speed steel is the most popular material, but specialized options like cobalt and carbide-tipped bits are growing in demand.

For homeowners with stucco exteriors, understanding drill bits is critical. Stucco’s abrasive composition of cement and sand requires carbide-tipped masonry bits to prevent cracking and ensure clean penetration. Using the wrong bit can create unsightly damage and compromise your home’s moisture barrier.

I’m Gabe Kesslick, a certified building envelope inspector with over two decades of experience. I’ve seen countless drilling mistakes on stucco homes lead to costly water intrusion. Understanding the right drill bits and techniques is essential for my inspection work and for teaching homeowners how to protect their stucco exteriors.

Decoding Drill Bit Materials and Coatings

Walk into any hardware store, and you’ll face rows of drill bits in different colors—gold, black, silver, bronze. These colors indicate the bit’s material and protective coating, which determine its durability and heat resistance.

Drilling creates intense friction and heat. A drill bit that can’t handle that heat will dull quickly or even snap. The right material and coating keep your bit sharp, extend its life, and prevent frustration.

Common Drill Bit Materials

The base material of a drill bit determines its hardness and heat tolerance.

High-Speed Steel (HSS) is the workhorse material, making up over 60% of all bits sold. It’s affordable and versatile, perfect for drilling wood, plastic, and soft metals. The “high-speed” name refers to its ability to withstand moderate heat, though it will dull if used on harder materials.

Cobalt bits are a blend of HSS and 5-8% cobalt, creating a much harder bit that excels at dissipating heat. When you’re facing stainless steel, cast iron, or other hardened metals, cobalt drill bits are your best choice. They cost more but last significantly longer on tough jobs.

Carbide bits offer extreme hardness, making them ideal for abrasive materials. Most often found as carbide tips on an HSS body, they are essential for drilling masonry, concrete, and tile. While incredibly wear-resistant, carbide is also brittle and can chip if handled improperly. For my work on stucco homes, carbide-tipped masonry bits are non-negotiable.

The Impact of Protective Coatings

Coatings add protection and improve the performance of the base material.

Titanium Nitride (TiN) is a ceramic coating that gives drill bits their distinctive gold color. It reduces friction and heat, which can increase a bit’s lifespan up to six times compared to uncoated bits. It’s an excellent value for general-purpose drilling.

Black oxide is a more modest coating that provides corrosion resistance and reduces heat buildup. While not as durable as TiN, it’s an affordable upgrade from uncoated steel bits and helps prevent rust.

Diamond coating is used for the toughest jobs. These specialized drill bits have industrial diamond particles bonded to their surface, allowing them to grind through extremely hard, brittle materials like glass, ceramic tile, and granite without causing cracks or chips.

A Guide to the Most Common Types of Drill Bits

While twist drill bits account for over 50% of global sales, many specialized options exist for a reason. Each bit type is engineered to solve a specific problem, from preventing splintering in hardwood to cleanly penetrating concrete. The construction industry consumes about 40% of all drill bits, proving that professionals know using the right bit is about safety, quality, and efficiency. Let’s explore the most common types.

General Purpose Drill Bits

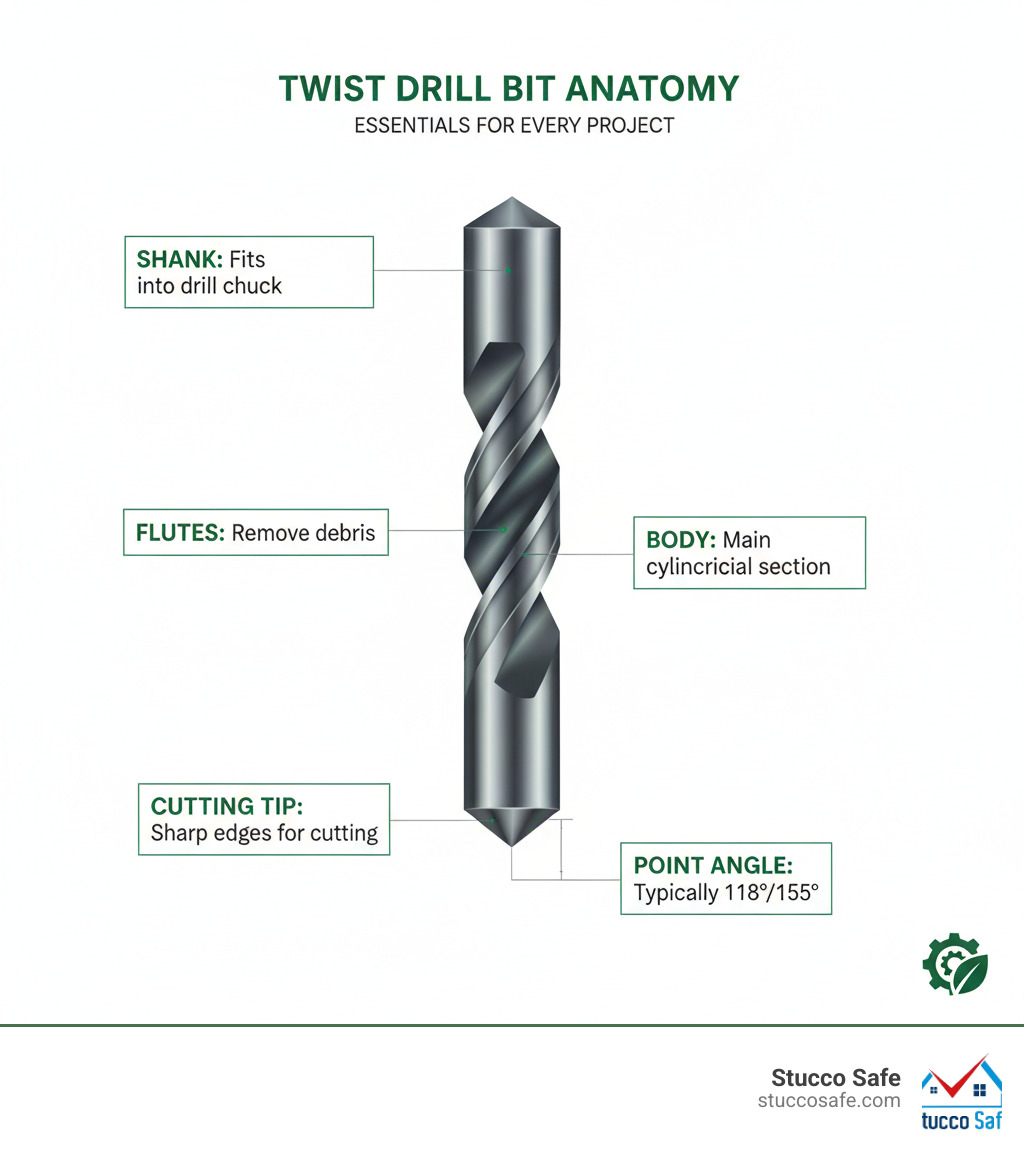

Twist Drill Bits are the workhorses found in every toolkit. Their helical flutes are designed to cut material while clearing chips and debris from the hole. They are available in HSS, cobalt, and with various coatings, making them suitable for most DIY projects involving wood, metal, and plastic.

Step Drill Bits feature a cone-like, stepped design that allows you to drill multiple hole sizes with a single bit. They are ideal for thin materials like sheet metal and plastic, and they automatically deburr the hole for a clean finish.

Wood-Specific Drill Bits

These bits are designed to work with wood’s grain to prevent splintering and produce clean results.

Brad-Point Bits offer precision for woodworking. A sharp center point prevents the bit from “walking,” while two outer spurs score the wood for exceptionally clean entry and exit holes, perfect for cabinetry.

Spade Bits prioritize speed and size. Their flat, paddle-shaped head bores large-diameter holes quickly in wood. The finish is rough, but they are perfect for rough carpentry, like drilling holes for wiring or plumbing.

Auger Bits excel at drilling deep, straight holes in thick wood. A screw-like tip pulls the bit into the material, while wide flutes efficiently clear chips, allowing for continuous drilling through beams and posts.

Forstner Bits create exceptionally clean, flat-bottomed holes. Their unique rim-guided design is ideal for installing concealed hinges or drilling overlapping holes and partial arcs on the edge of a workpiece.

Metal-Specific Drill Bits

Drilling metal requires bits that can withstand high heat and friction.

Cobalt Bits are the solution for hardened metals. Their cobalt alloy provides superior heat resistance, allowing them to maintain a sharp edge when drilling stainless steel, cast iron, or titanium.

Left-Hand Drill Bits are problem-solvers that cut counter-clockwise. Used with a reversible drill, their rotation can grip and unscrew broken bolts or screws as you drill into them.

Annular Cutters are used in metal fabrication for drilling large-diameter holes efficiently. Instead of grinding away all the material, they cut only the hole’s circumference, leaving a solid slug. This method is faster and requires less power.

Masonry, Tile, and Glass Drill Bits

Hard, brittle materials require specialized bits to prevent cracking.

Masonry Bits feature a hardened steel body with a carbide tip designed to pulverize concrete, brick, and stucco, especially when used with a hammer drill. For homeowners, using the right Masonry Drill Bit for Concrete is essential to avoid damaging stucco.

Tile & Glass Bits have a spear-shaped carbide tip that gently scores the material rather than cutting it aggressively. This prevents cracking in ceramic, porcelain, and glass. Use them at low speeds with a coolant.

Diamond Hole Saws are the ultimate choice for the hardest materials like porcelain, granite, and marble. Industrial diamond particles on the cutting edge grind through materials that would destroy other bits. For more guidance, see our guide on How to Drill Into Stucco.

Choosing and Maintaining Your Drill Bit Collection

A good set of drill bits is an investment. Like any quality tool, the right collection, properly cared for, will deliver better results and last for years. Making smart choices upfront can be the difference between a frustrating project and a satisfying one.

How to Choose the Right Drill Bit Set

The “right” set depends on your projects. For general home repairs, a standard fractional set (1/16 to 1/2 inch) of high-speed steel (HSS) bits is sufficient. If you frequently work with hard metals, investing in cobalt bits is wise. For any masonry or stucco work, carbide-tipped bits are essential.

Don’t be swayed by a high piece count. A smaller set of high-quality bits is far more useful than a massive collection of mediocre ones. Focus on quality materials and performance-enhancing coatings like titanium nitride (TiN), which can extend bit life up to six times. Also consider the length: standard “jobber” length is versatile, while “stubby” bits are great for tight spaces and “long” bits are for reaching through thick materials.

Best Practices for Using and Maintaining Your drill bits

Proper technique and maintenance will make even the best drill bits last longer.

Match drill speed to the material. A general rule is: the harder the material and the larger the bit, the slower the speed. Drilling too fast, especially in metal, generates excessive heat that can permanently ruin the bit’s temper.

Apply steady, consistent pressure. Let the bit do the work. Too little pressure causes rubbing and heat, while too much can cause the bit to break.

Use pilot holes for larger diameter holes. Drilling a small guide hole first reduces strain on the larger bit and ensures accurate placement.

Prevent “bit walking” on smooth surfaces by using a center punch to create a small starting divot. Brad-point bits for wood and split-point tips on twist bits also solve this problem.

Avoid overheating. If you see smoke or discoloration, slow down, pull the bit out periodically to cool, and clear debris from the hole.

Use cutting fluid when drilling metal. This inexpensive accessory reduces friction, dissipates heat, and dramatically extends the life of your drill bits.

Keep bits sharp. A dull bit is inefficient and produces rough holes. A drill bit sharpener is a worthwhile investment for anyone who drills regularly. Store your bits in a case to protect their cutting edges.

Drilling into Stucco and Other Masonry

Drilling into exterior walls like stucco presents unique challenges. It’s not just about making a hole; it’s about protecting your home’s integrity. The abrasive nature of masonry means standard drill bits and techniques are ineffective and can cause significant damage.

Why Stucco Requires Special Drill Bits

Stucco is a mixture of cement, sand, and water, creating a rock-hard, abrasive surface. A standard HSS drill bit will dull almost instantly against it, generating excess heat and pressure that can crack the stucco. These cracks compromise your home’s moisture barrier, potentially leading to water intrusion.

Furthermore, the fine dust created during drilling clogs the flutes of standard bits, trapping heat and making the process inefficient. This is why carbide-tipped masonry bits are essential for stucco. The hard carbide tip grinds through the abrasive material without dulling, and the bit’s wide flutes are designed to clear masonry dust effectively. Our guides on What Drill Bits Can I Use for Stucco? and Drill Bit Stucco offer more specific recommendations.

The Best Technique for Drilling Stucco

The right bit is only half the battle; proper technique is crucial to avoid damage. Always select a carbide-tipped masonry bit and use a hammer drill if possible. The drill’s hammering action pulverizes the material as it spins, making the work faster and cleaner.

Mark your location carefully. For larger holes, first drill a smaller pilot hole to guide the larger bit accurately.

To begin, start drilling at a slow speed with the hammer function turned off. This creates a small indentation that prevents “bit walking.” Once the bit is seated, engage the hammer function and increase to a moderate speed.

Apply firm, steady pressure, but don’t force the drill. Let the tool do the work. Periodically pull the bit from the hole to clear dust and allow it to cool. This simple step prevents overheating and keeps the bit cutting efficiently.

Keep the drill perfectly perpendicular to the wall to ensure a round hole and prevent stress that could crack the stucco.

For a complete walkthrough, our article on the Best Way to Drill Into Stucco provides step-by-step guidance. These principles also apply to other masonry, as detailed in our Cement Drill Bit and Masonry Drill Bit for Concrete guides. Always use the Best Drill Bit for Stucco to protect your home.

Conclusion: Making the Right Choice for Your Project

We’ve covered everything from bit anatomy to materials and coatings. The key takeaway is simple: matching your drill bit to the material is crucial for professional results. Use High-Speed Steel (HSS) for general tasks, cobalt for hard metals, and carbide-tipped bits for masonry like concrete and stucco.

Coatings like Titanium Nitride (TiN) extend a bit’s life, and a quality set is a better investment than a large, cheap one. Proper care—using the right speed, applying steady pressure, and using cutting fluid for metal—will make your investment last.

For those of you with stucco exteriors, you now know that carbide-tipped masonry drill bits and proper technique are non-negotiable. A cracked stucco surface isn’t just unsightly; it can compromise your home’s moisture barrier and lead to serious problems. The abrasive nature of stucco demands the right tools.

At Stucco Safe, we’ve spent over two decades inspecting stucco homes across Southeastern Pennsylvania, New Jersey, and Delaware. We’ve seen what happens when homeowners use the wrong tools. While this guide can help you tackle projects safely, we’re here if you need professional guidance. Our forensic testing methods can identify moisture intrusion issues before they become expensive repairs. Stucco inspections vary in cost from $495 to $1595 or more for very large homes, but that investment often saves thousands in potential repair costs.

If you’re planning any drilling work on your stucco exterior, make sure you’re using the Best Drill Bit for Stucco for the job. Your home’s integrity depends on it, and we’re here to help ensure every project protects rather than compromises that integrity.

Happy drilling, and remember – the right bit for the right job isn’t just good practice, it’s good sense.