Stucco Inspection Standards: 3 Essential Steps

Why Stucco Inspection Standards Matter for Your Home’s Health

Stucco inspection standards provide the framework professionals use to evaluate the condition of your home’s exterior cladding—and understanding them can save you from hidden damage that might cost tens of tens of thousands to repair. Whether you’re buying, selling, or simply maintaining a stucco-clad home, these standards define what inspectors look for, how they test, and what constitutes a problem worth addressing.

Key Stucco Inspection Standards at a Glance:

- EDI (Exterior Design Institute) Standards of Practice – The primary framework for certified stucco inspectors

- ASTM Standards – Industry benchmarks including C926 (Application), C1063 (Lathing), C1860 (Bond Strength), and C1861 (Accessories)

- InterNACHI Phase I Standards – Guidelines for exterior wall cladding inspections

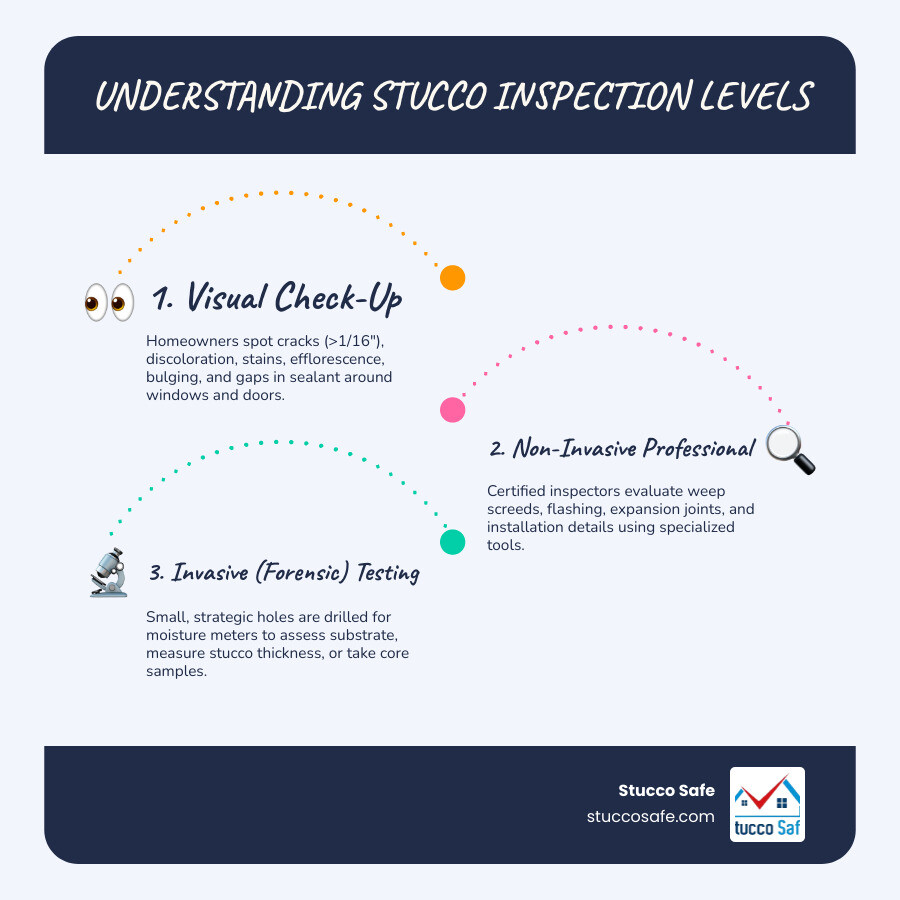

- Three Inspection Levels – Visual, Non-Invasive, and Invasive (forensic) testing

- HUD NSPIRE Standards – Federal guidelines for wall covering deficiencies

Here’s the reality: 50% of stucco homes may not have sufficient waterproofing and flashing, making them vulnerable to moisture damage that often remains invisible until it’s severe. A crack as small as 1/16″ can allow water behind your stucco, where it quietly rots wood framing and breeds mold.

Stucco inspection standards exist because a visual check isn’t enough. The stucco itself is often the last component to show distress—by the time you see dark stains, bulging, or interior wall damage, the problem has likely been festering for months or years. Professional standards guide inspectors to look beyond the surface, using moisture meters, thermal imaging, and invasive probing to detect hidden issues before they become structural nightmares.

The stakes are high. Homes built between 1980 and 2021 are particularly vulnerable due to evolving building codes and installation practices. Without proper expansion joints, weep screeds, kickout flashing, and weather-resistive barriers, moisture finds its way in. And once it does, the clock starts ticking on your home’s structural integrity.

I’m Gabe Kesslick, and I’ve been detecting and repairing stucco leaks since 2001, with certifications including EDI Level 2 Certified Stucco Inspector and BESI Level 2 Certified Building Envelope Forensic Inspector, which means I apply stucco inspection standards daily to help homeowners understand what’s really happening behind their walls. This guide will walk you through exactly what those standards are, why they matter, and how they protect your investment.

Simple stucco inspection standards glossary:

The Anatomy of a Stucco Inspection: From Visual to Invasive

Stucco inspections happen in stages, from a simple visual check to a detailed forensic analysis. Each level reveals more about your stucco’s health, moving from surface-level clues to hidden problems that require specialized tools and expertise. This tiered approach is a core part of comprehensive stucco inspection standards.

The Initial Visual Check-Up

This is where every inspection begins, and it’s something homeowners can do regularly. A keen eye can spot early warning signs, although these often only hint at deeper problems. We look for:

- Cracks: Not all cracks are created equal. Hairline cracks might be cosmetic, but a crack as small as 1/16 of an inch wide can permit water to enter behind the stucco, especially if there’s no moisture barrier. Larger cracks (over 1/16th of an inch) are a serious red flag.

- Discoloration and Stains: Dark spots, streaks, or general discoloration on the stucco surface can indicate moisture intrusion. These often appear around windows, doors, or where the roof meets the wall.

- Efflorescence: This is a white, powdery mineral deposit that appears on the stucco surface. It’s a clear sign that water is moving through the material, dissolving salts, and depositing them on the exterior as it evaporates. It suggests water intrusion.

- Bulging or Soft Spots: If the stucco feels soft, spongy, or appears to be bulging outwards, it’s a strong indicator of moisture trapped behind the cladding, potentially leading to rot or delamination.

- Gaps in Sealant: Inspect the sealant around windows, doors, and other penetrations. Gaps or deteriorated caulk create direct pathways for water to seep behind the stucco.

These visual cues are like your home’s way of telling you something’s amiss. While valuable, they typically only show the symptoms of a problem, not the cause or extent of hidden damage.

Non-Invasive Professional Assessment

When we conduct a non-invasive inspection, we go beyond what the average homeowner might notice. This is a visual evaluation performed by a certified inspector, often following stringent stucco inspection standards like those from the Exterior Design Institute (EDI). We carefully check how the stucco was installed to determine if it meets current best practices and building codes. This includes:

- Weep Screed Presence and Condition: A weep screed is a crucial component at the base of your stucco system. It’s a metal flashing that creates a gap, allowing any moisture that gets behind the stucco to drain out and preventing groundwater from wicking up into the wall. Without a weep screed, or if it’s clogged with debris or soil, water gets trapped, leading to moisture damage.

- Flashing Details: Proper flashing is your home’s armor against water. We inspect areas like kickout flashing (which diverts water away from the wall where a roofline terminates), window and door flashing, and flashing at roof-to-wall intersections. Improper or missing flashing is a primary cause of water intrusion.

- Expansion Joints: These are essential breaks in the stucco surface that allow for natural expansion and contraction due due to temperature changes and building movement. Without them, or if they’re improperly placed, stress can lead to significant cracking.

A non-invasive assessment provides a comprehensive overview of your stucco’s exterior integrity and installation quality, often revealing systemic flaws that a casual glance would miss.

Invasive (Forensic) Testing

When a non-invasive inspection raises concerns, or if we suspect hidden moisture, we move to invasive (forensic) testing. This is the most thorough level of inspection and adheres to the highest stucco inspection standards, allowing us to truly see what’s happening behind the surface.

Our invasive inspection process involves:

- Drilling Small, Strategic Holes: We carefully drill small holes, typically two 1/4 inch holes side-by-side, in discreet locations. These locations are chosen based on visual indicators, thermal imaging readings, or areas known to be prone to moisture intrusion.

- Using a Moisture Meter: Through these holes, we insert a two-prong moisture probe. This specialized tool measures the electrical resistance of the wood sheathing and framing behind the stucco. Any liftd readings are a clear sign of moisture intrusion into the building’s structure. We use professional-grade meters, like Extech, which provide accurate moisture content readings.

- Assessing Substrate Condition: Beyond just moisture, a resistance probe can help us determine the integrity of the substrate and framing. Water-damaged wood will have compromised structural integrity.

- Measuring Stucco Thickness: In some cases, we measure the stucco’s thickness, as proper thickness (ideally 3/4 to 1 inch) is important for its longevity and performance.

- Core Sampling for Severe Cases: If moisture readings are consistently high and the integrity of the material behind the stucco is significantly in question, we might recommend core sampling. This involves carefully drilling a 1-inch cutout of the stucco to visually inspect the underlying layers for mold, rot, or insect activity.

- Sealing Test Holes: After each test, we carefully seal the drilled holes with color-matched, waterproof caulk, ensuring no new pathways for moisture are created and preserving your home’s aesthetic.

This invasive testing provides definitive answers about the presence, location, and extent of hidden moisture damage, allowing us to provide precise recommendations for remediation.

The Professional’s Playbook: Key Stucco Inspection Standards and Protocols

A professional stucco inspection isn’t just about looking at a wall; it’s a systematic process guided by rigorous stucco inspection standards. We follow these protocols to ensure objectivity, thoroughness, and accuracy in our assessments, providing you with reliable information about your home’s condition.

Adhering to Industry Stucco Inspection Standards

Our certified stucco inspectors adhere to the most respected industry stucco inspection standards. This commitment ensures that our evaluations are consistent, comprehensive, and based on established best practices.

- Exterior Design Institute (EDI): We proudly follow the Exterior Design Institute (EDI) Standards of Practice. Our inspectors are EDI Certified, which means they have undergone specialized training and testing to understand the unique challenges of stucco systems. You can learn more about these standards at Exterior Design Institute (EDI) Standards of Practice We follow theExterior Design Institute (EDI) Standards of Practice. Our Stucco Inspectors are EDI Certified. Our full credentials are listed under each inspector.Read more about our team!.

- InterNACHI Standards: We also align with the International Phase I Standards of Practice for Inspecting Exterior Wall Cladding, as detailed by InterNACHI. This framework provides a standardized approach to inspecting various exterior claddings, including stucco. A Phase I inspection is limited to readily accessible and visible portions and does not require intrusive testing, water testing, or the use of infrared cameras for definitive moisture content, though thermal imaging is a useful diagnostic tool. We advise clients that all exterior wall claddings should be inspected not less than annually. For more details, see International Phase I Standards of Practice for Inspecting Exterior Wall Cladding .

- HUD NSPIRE Standards for Wall Coverings: For general exterior wall condition, we consider guidelines such as the HUD NSPIRE standards. These national standards for physical inspection of real estate address deficiencies like missing wall covering sections (1 sq ft or more), holes penetrating to the interior, peeling paint (10 sq ft or more on walls built after 1978), and evidence of structural failure. These deficiencies often have a 30-day correction timeframe.

By integrating these diverse stucco inspection standards, we provide a holistic and highly reliable assessment of your stucco system.

The Role of ASTM Standards in Stucco Quality

ASTM International plays a critical role in developing and coordinating stucco inspection standards and best practices for the entire industry. Their committee on gypsum and related building materials and systems (C11) has a dedicated stucco work group that has been actively working since 2013 to address historical inconsistencies and create a more unified approach.

Key ASTM standards relevant to stucco include:

- ASTM C926 (Standard Specification for Application of Portland Cement-Based Plaster): Governs best practices for applying stucco over various substrates.

- ASTM C1063 (Standard Specification for Installation of Lathing and Furring to Receive Interior and Exterior Portland Cement-Based Plaster): Covers the proper installation of lathing and fasteners, which is crucial for stability.

- ASTM C1860 (Standard Test Method for Testing the Bond Strength of Portland Cement-Based Plaster to a Wall as Related to Lateral Forces): Provides a method for testing the bond strength of stucco to a wall.

- ASTM C1861 (Standard Specification for Lathing Accessories and Lathing Fasteners for Portland Cement-Based Plaster): Defines the product standards for lathing accessories and fasteners.

These standards, developed by a wide range of industry experts, are critical benchmarks for proper installation and directly inform our inspection process.

Specialized Tools of the Trade

Our adherence to rigorous stucco inspection standards is greatly improved by the specialized tools we employ. These instruments allow us to detect issues that are impossible to see with the naked eye, providing a forensic level of detail in our inspections.

- Moisture Meters (Probe and Scan): These are our primary tools for detecting hidden water. We use non-invasive surface scanners to find potential problem areas, then use probe meters (like those from Delmhorst or Extech) to get precise moisture readings from the underlying wood structure, confirming the presence and severity of water intrusion.

- Thermal Imaging Cameras (Infrared): While not providing direct moisture content, thermal imaging cameras are invaluable diagnostic tools. They detect subtle temperature variations on the stucco surface. Areas with trapped moisture often appear cooler (due to evaporation or thermal bridging) or warmer (due to solar loading on wet materials) than surrounding dry areas. This helps us pinpoint areas for further, more invasive testing.

- Borescopes: These tiny cameras on flexible tubes can be inserted into small openings to visually inspect concealed spaces behind the stucco, such as wall cavities, for signs of mold or rot.

- Core Sampling Tools: As mentioned, these allow for the removal of small stucco samples for direct visual examination of all layers and the underlying substrate.

These specialized tools, combined with our certified expertise, allow us to uncover hidden issues, accurately assess damage, and provide you with the most thorough and reliable stucco inspection possible in Southeastern PA, New Jersey, and Delaware.

Common Stucco Failures and Their Consequences

Neglecting proper stucco inspection standards and maintenance can lead to a cascade of problems. What might seem like a small crack can quickly become a gateway for significant and costly damage, often silently festering behind your home’s exterior.

The Silent Destroyer: Water Intrusion

Water is stucco’s biggest enemy, especially in humid, rainy climates like Southeastern PA, New Jersey, and Delaware. When water gets behind the cladding, it becomes a silent destroyer.

- Leaks Behind the Cladding: Small cracks, gaps in sealants, or improperly installed flashing create pathways for water to bypass the stucco’s protective layer. Once behind, this water can get trapped, especially in barrier EIFS systems.

- Flashing Failures: Improper or missing flashing, particularly kickout flashing at roof-to-wall intersections, allows water to run directly down the wall and behind the stucco. This can lead to substantial moisture accumulation and decay.

- Sealant Breakdown: Over time, caulk around windows, doors, and other penetrations degrades, cracks, or loses adhesion, creating direct entry points for moisture.

- Rot in Wood Sheathing and Framing: Once water penetrates, it saturates the wood sheathing and framing. This leads to wood rot, compromising the structural integrity of your home. This can be extensive, causing framing to collapse.

- Mold Growth: Constant dampness behind the stucco creates an ideal environment for mold and mildew to flourish. This can impact indoor air quality and lead to health issues for occupants.

The danger of water intrusion is its stealth. By the time you notice visible signs like dark stains, bulging stucco, or interior water damage, the problem has often become severe and expensive to repair. We’ve seen this happen far too often, turning a minor issue into a major remediation project. More on water damage and its impacts can be found at water damage Water is one of the biggest enemies of stucco, and areas with frequent rain or high humidity are particularly at risk. Water can seep into small cracks or gaps around windows and doors, leading tomoisture intrusion. This can cause the stucco to bulge or soften, indicating potential mold or rot behin….

Climate and Regional Factors

Our regional climate in Southeastern PA, New Jersey, and Delaware significantly impacts stucco performance and underscores the need for diligent inspections guided by stucco inspection standards.

- Impact of High Humidity: Persistent high humidity can keep stucco damp for longer periods, increasing the risk of moisture penetration and hindering its ability to dry out.

- Freeze-Thaw Cycles: Our winters bring freeze-thaw cycles. Water that enters small cracks in the stucco can freeze, expand, and then thaw. This repeated action exacerbates existing cracks and creates new ones, leading to more widespread damage.

- Temperature Fluctuations: Significant temperature swings cause stucco to expand and contract. If expansion joints are missing or improperly installed, these movements create stress points, resulting in cracking and separation from the substrate.

These regional factors make regular, professional stucco inspections not just a recommendation, but a necessity to protect your home from premature deterioration.

After the Inspection: Costs, Remediation, and Prevention

Finding issues during a stucco inspection can be daunting, but it’s also an opportunity to protect your home and prevent further, more costly damage. Understanding the next steps, from costs to remediation and ongoing maintenance, is key.

Decoding the Stucco Inspection Report and Costs

Once our inspection is complete, we provide you with a detailed report outlining our findings. This report will clearly identify any deficiencies, moisture readings, and recommended actions, all based on established stucco inspection standards.

- Typical Cost Range: The cost of a stucco inspection typically ranges from $495 to $1595 for a standard-sized home. This range reflects the thoroughness of the process, including visual, non-invasive, and invasive testing.

- Factors Influencing Price: Several factors can influence the final price, including:

- Home Size: Larger homes naturally require more time and effort to inspect.

- Stucco Type: Different stucco systems (e.g., EIFS vs. traditional hard coat) may have unique inspection nuances.

- Accessibility: Homes with difficult-to-access areas may incur additional costs.

- Severity of Damage: If extensive issues are suspected, more invasive testing might be required, impacting the overall cost.

- Understanding the Report Findings: Our reports are clear and actionable, including photos, specific moisture readings, and detailed recommendations.

- Limitations of an Inspection: While our forensic inspections are thorough, they cannot guarantee the findy of all hidden defects. We focus on accessible and high-risk areas based on our expertise and diagnostic tools. Severe, widespread issues may require further investigation, such as full stucco removal.

The Path to Stucco Remediation

If our inspection uncovers problems, remediation is the next critical step. This process isn’t just about patching; it’s about correcting underlying issues to restore your stucco’s integrity and prevent future damage.

- Assessing the Extent of Damage: The first step is to fully understand how widespread the water damage is. Our detailed reports guide this assessment.

- Removing Failed Stucco: Damaged or improperly applied stucco must be carefully removed from the affected areas.

- Repairing or Replacing Rotted Sheathing/Framing: This is crucial. Any wood that has rotted due to moisture must be repaired or replaced to restore the structural integrity of your home.

- Installing a New Weather-Resistive Barrier (WRB): A proper WRB is the second line of defense against water. It’s installed over the sheathing to shed any water that gets past the stucco.

- Re-applying Stucco Correctly: New stucco is then applied, adhering strictly to current building codes and stucco inspection standards, ensuring proper layering, thickness, and curing.

- Ensuring Proper Drainage: This is a critical part of remediation. We ensure that proper flashing, weep screeds, and expansion joints are installed or repaired according to best practices to allow water to drain effectively and prevent future intrusion.

Proactive Stucco Maintenance for Homeowners

Prevention is always better (and cheaper!) than a cure. By taking proactive maintenance steps, you can significantly prolong the life and integrity of your stucco exterior. Here’s a checklist we recommend for homeowners in Southeastern PA, New Jersey, and Delaware:

- Annual Check-ups: Perform a visual inspection of your stucco annually. Look for new cracks, discoloration, bulging, or gaps in sealant.

- Cleaning Stucco Surfaces: Periodically clean your stucco to remove dirt, mold, and mildew. Use a low-pressure wash and appropriate cleaning solutions to avoid damaging the finish.

- Repairing Caulk and Sealants: Inspect all sealant around windows, doors, pipes, and other penetrations semi-annually (at least annually). Promptly repair any caulk that is cracked, split, or losing adhesion with a high-quality, compatible sealant.

- Monitoring Weep Screeds for Blockages: Ensure that the weep screed at the base of your stucco is clear of debris, landscaping, or paint. Blockages prevent proper drainage.

- Promptly Addressing Small Cracks: Don’t ignore small cracks. While not all are critical, addressing them quickly with appropriate patching materials can prevent them from becoming entry points for water.

By following these simple steps and scheduling regular professional inspections, you can help ensure your stucco remains a beautiful and protective facade for your home.

Frequently Asked Questions about Stucco Inspection Standards

We often hear similar questions from homeowners regarding stucco inspection standards. Here are some of the most common ones we address:

What is the most serious problem a stucco inspection can find?

The most serious issue a stucco inspection can uncover is widespread water intrusion hidden behind the stucco. This can lead to extensive rot of the home’s structural components, such as wood sheathing and framing, which compromises the building’s integrity and can lead to very costly repairs. In severe cases, we’ve seen structural failure that threatens the safety of the entire building. The insidious nature of this problem is that it often goes undetected for years, silently causing damage until it manifests as a major structural issue or widespread mold.

How much does a professional stucco inspection cost?

A professional stucco inspection typically costs between $495 and $1,595 for a standard-sized home in our service areas of Southeastern PA, New Jersey, and Delaware. The final price depends on factors like the house’s size, the complexity of the architecture (e.g., numerous windows, doors, or architectural features), and the type of stucco system (e.g., EIFS vs. traditional hard coat). Larger or more complex homes, or those requiring more extensive invasive testing, will be at the higher end of this range.

How often should I get my stucco inspected?

Homeowners should perform a visual check of their stucco annually, looking for cracks, stains, or other visible irregularities. However, a comprehensive, professional inspection that adheres to established stucco inspection standards is recommended every 4-5 years. You should also definitely get an inspection when buying or selling a property, or immediately if you notice any persistent signs of trouble like new cracks, dark stains, bulging, or efflorescence. For homes built between 1993 and 2006, which have a significantly higher failure rate due to past building code issues, more frequent inspections might be advisable.

Conclusion

Understanding and adhering to stucco inspection standards is not just about compliance; it’s about safeguarding your most significant investment—your home. From the initial visual assessment to non-invasive techniques and the precision of forensic testing, each step in the inspection process is designed to uncover hidden vulnerabilities and protect your property from the silent threat of water damage.

Proactive care and regular, professional inspections are your best defense. By staying vigilant and addressing issues promptly, you can ensure your stucco exterior remains strong, beautiful, and performs its critical role in protecting your home’s structural integrity. Don’t let hidden moisture turn a small problem into a costly nightmare.

For certified, forensic-level testing and adherence to the highest stucco inspection standards in Southeastern PA, New Jersey, or Delaware, a professional service like ours ensures peace of mind.