Drill Bit Sets: Ultimate Guide 2025

Why the Right Drill Bit Set Matters for Every Project

Drill bit sets offer the versatility, organization, and cost savings every homeowner and DIYer needs to tackle projects with confidence. Whether you’re hanging pictures, assembling furniture, or working on your home’s exterior, having the right bits on hand eliminates frustration and ensures professional results.

Quick Answer: What to Look for in Drill Bit Sets

- Material: High-Speed Steel (HSS) for general use, Cobalt for hard metals, Carbide-tipped for masonry

- Coating: Black Oxide or Titanium Nitride for durability and rust resistance

- Tip Design: 135° split point prevents walking on hard surfaces

- Shank Type: Hex shanks for impact drivers, round shanks for standard drills

- Set Size: 12-115 pieces depending on your project needs

- Popular Options: The JEFE HEX 13-Piece Set (4.6/5 stars, 2,969 reviews) and Milwaukee SHOCKWAVE 23-Piece Set

From hanging a picture frame to drilling into stucco, the right drill bit makes all the difference. A quality drill bit set gives you the range of sizes and types you need without the clutter and higher cost of buying individual bits. Investing in a complete set means you’ll save money, keep everything organized, and have the versatility to handle wood, metal, plastic, and masonry.

This guide breaks down everything from High-Speed Steel versus Cobalt construction to the significance of split point tips and impact-ready designs. You’ll learn which sets work best for specific materials, how coatings extend bit life, and what features truly matter for your projects.

I’m Gabe Kesslick, and with my expertise in stucco inspection and building envelope forensics, I’ve spent decades working with drill bit sets on job sites. I understand how critical the right tools are for precise, damage-free installations in sensitive materials like stucco. Selecting the proper drill bit set prevents costly mistakes and ensures lasting results.

Decoding Drill Bit Materials and Coatings

Think of drill bits like ingredients in a recipe—the material you choose determines what you can successfully create. A drill bit set made from the wrong material for the job will only lead to frustration.

The material and any protective coatings directly affect performance, longevity, and which materials they can drill through. Let’s break down what makes each type special.

Drill Bit Materials

High-Speed Steel (HSS) is the workhorse of the drill bit world. It’s the most common material in general-purpose drill bit sets because it’s economical and handles everyday tasks like drilling into wood, plastic, and soft metals. HSS bits can handle higher temperatures than older carbon steel bits, meaning they stay sharp longer during normal use.

When you need to tackle tougher metals, Cobalt (HSS-Co) bits are the answer. These are HSS bits with cobalt alloyed into the steel—usually 5% (M35) or 8% (M42). This addition makes a huge difference when drilling through stainless steel or cast iron. The M42 variety is particularly impressive for high-tensile materials, handling the intense heat they generate.

For the absolute toughest materials, Carbide-Tipped bits are your best friend. They feature an extremely hard carbide insert brazed onto a steel body, making them perfect for drilling into concrete, brick, stone, and masonry—materials common in homes throughout Southeastern Pennsylvania, New Jersey, and Delaware. While carbide can chip with sideways pressure, nothing else comes close for masonry work.

Performance Effects

The material choice directly impacts performance. Heat resistance is crucial because drilling creates friction and heat. Cobalt and carbide bits excel here, maintaining their sharp edges under high temperatures where HSS bits would dull. This leads to greater durability, as premium materials resist wear and keep a sharp cutting edge longer. Finally, hardness determines what a bit can cut. Carbide is the hardest, followed by cobalt and HSS, which is why an HSS bit will fail against abrasive concrete.

Drill Bit Coatings

Many drill bit sets come with coatings that boost performance. Black Oxide is a common coating that protects against corrosion and rust while slightly reducing friction. DEWALT’s black and gold finish is a good example that targets rust prevention and extended bit life.

Titanium Nitride (TiN) is the distinctive gold-colored ceramic coating on many premium bits. It significantly increases surface hardness and wear resistance, while also reducing friction for smoother drilling and less heat. The JEFE HEX 13-Piece Drill Bits Set uses titanium HSS twist drill bits and has earned an impressive 4.6 out of 5 stars from 2,969 reviews. Milwaukee’s SHOCKWAVE Impact Duty™ RED HELIX™ Titanium Drill Bit Set is another excellent example.

These coatings provide real advantages like rust prevention, friction reduction, and extended life. By increasing hardness and reducing wear, coatings help your drill bit set last significantly longer and perform better throughout its life.

Key Features That Define Performance

After choosing the right material and coating for your drill bit set, look at the design features that separate good bits from great ones. These details make the difference between a clean hole and a frustrating experience.

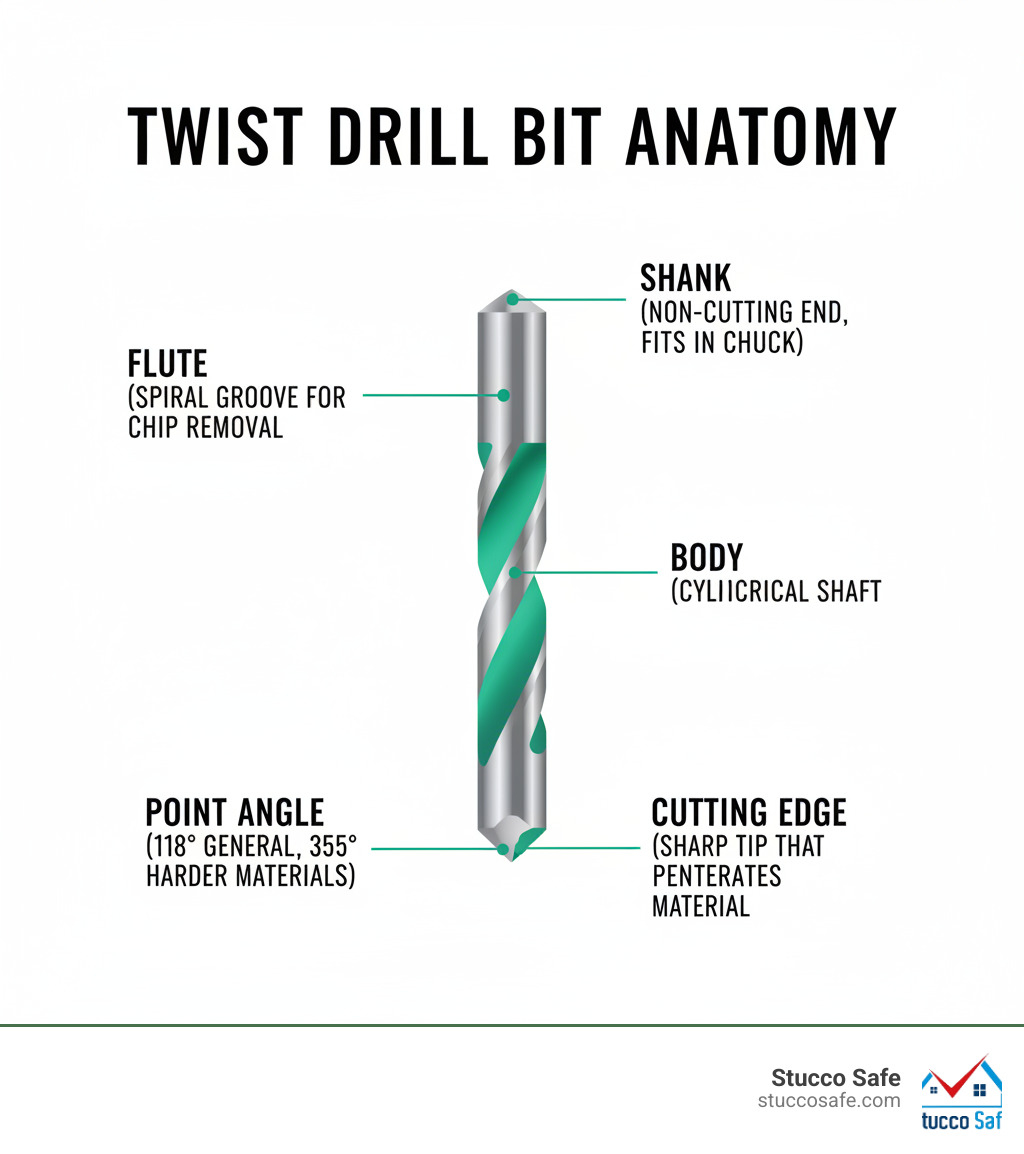

Tip Design

The tip of your drill bit is where the work happens. If you’ve ever watched a bit skate across a surface before catching, you know what “walking” means.

Split point tips solve this problem. These bits have a tip ground to create two cutting edges that bite into the material immediately. The DEWALT IMPACT READY® Metal Drill Bit Set features this 135° split point design to resist walking on hard surfaces. This self-centering feature is invaluable when you need a precise hole, like when mounting fixtures on stucco.

Point Angles

The angle of the bit’s tip affects performance in different materials.

A 118° angle is for general-purpose use. This sharper angle bites quickly into softer materials like wood and plastic. It’s the standard angle on most HSS twist bits.

For harder materials like metal, a 135° angle is best. This flatter angle creates a stronger cutting edge that resists dulling. Combined with a split point, these bits are far less likely to walk on slippery metal surfaces. You’ll find this angle on cobalt and titanium-coated bits for metalworking.

Shank Types

The shank type is crucial for a secure fit in your drill. The wrong type can lead to slippage, wobbling, and broken bits.

Round shanks are the classic design for standard drill chucks and work perfectly for most general drilling tasks.

Hex shanks (usually 1/4 inch) provide a more secure grip in quick-change chucks and impact drivers, preventing slippage under high torque. Both the JEFE HEX 13-Piece Set and the DEWALT IMPACT READY® sets feature hex shanks for this reason.

SDS shanks are specialized for rotary hammer drills. Grooves on the shank allow the bit to slide back and forth, enabling the hammering action used to pulverize masonry and concrete.

Impact Drivers vs. Standard Drills

Understanding your tools is critical. Impact drivers deliver powerful rotational blows that can destroy standard drill bits.

IMPACT READY® bits are engineered for this punishment, with reinforced hex shanks and tapered cores to resist breakage under intense torque. The DEWALT IMPACT READY® sets exemplify this design.

Standard drills use continuous rotation and are more forgiving. They work well with traditional round-shank bits and are often better for precision work requiring more control.

When you’re ready to expand your toolkit, you’ll find a comprehensive selection of options at CML Supply, where you can match the right drill bit sets to your specific tools and projects.

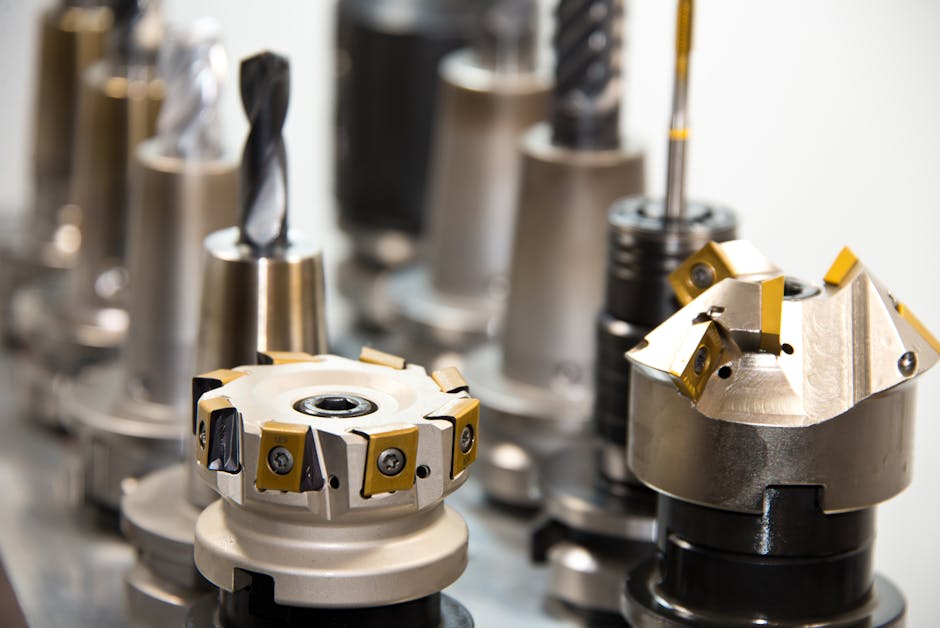

A Guide to the Best Types of Drill Bit Sets

Now that we’ve covered the basics, let’s look at the different types of drill bit sets. You need specific bits for various tasks, whether you’re in your workshop or tackling home improvements around Philadelphia or Cherry Hill.

General-Purpose & Multi-Material Drill Bit Sets

Think of these as the Swiss Army knife of your toolkit, handling everyday tasks from assembling furniture to hanging shelves. They excel with softer materials like wood, plastic, and light metals and are the go-to choice for homeowners in Southeastern PA, New Jersey, and Delaware.

These sets typically feature High-Speed Steel (HSS) twist bits, often with black oxide or titanium nitride (TiN) coatings for rust prevention and improved durability. They offer excellent value and versatility for most home projects.

The JEFE HEX 13-Piece Drill Bits Set is a perfect example, with titanium HSS twist bits earning an average rating of 4.6 out of 5 stars from 2,969 reviews. The Makita Bit & Hand Tool Metric 71-Pieces Kit is another comprehensive option, including HSS titanium bits for metal, wood, and masonry, plus screwdriver bits and accessories.

Specialized Drill Bit Sets for Masonry and Stucco

When your project involves drilling into hard, abrasive materials like concrete, brick, stone, and stucco, standard bits won’t work. You need specialized drill bit sets for the job.

These sets are your solution for mounting fixtures, installing cameras, or adding decorations to your home’s exterior. The stars of these sets are carbide-tipped masonry bits. The exceptionally hard carbide tip chips away at tough materials without dulling quickly. For heavy-duty work, look for bits with SDS shanks designed for hammer drills.

The Lytool 10Pcs Masonry Drill Bits Kit has earned an average rating of 4.0 out of 5 stars from 923 reviews, demonstrating its reliability for masonry tasks.

Drilling into stucco requires special care to avoid damage. As a stucco inspector, I’ve seen how the wrong bit or technique can lead to costly repairs. For detailed information, check our guide on How to Drill into Stucco. Choosing the right cement drill bit is vital; learn more in our articles on What Drill Bits Can I Use for Stucco and using a masonry drill bit for concrete.

Woodworking & Metalworking Sets

For tasks demanding precision, dedicated woodworking and metalworking drill bit sets are worth their weight in gold. These specialized sets go beyond general-purpose drilling to deliver professional-quality results.

Woodworking sets may feature brad-point bits for clean, precise holes; spade bits for quickly boring larger holes; and Forstner bits for clean, flat-bottomed holes needed for hinges.

Metalworking sets feature cobalt HSS bits for hard metals like stainless steel or titanium-coated HSS bits for general metal drilling. Look for a 135° split point tip, which prevents bit walking and makes it easier to start holes in hard metal surfaces, whether you’re in a workshop in King of Prussia or a garage in Bayonne.

These specialized sets are indispensable for furniture making, metal fabrication, automotive repair, and other precise projects.

Specialty & Extraction Sets

Sometimes the job is about fixing a problem, not making a new hole. That’s where specialty and extraction drill bit sets come in.

Screw extractors have reverse threads that grip a stripped or broken screw head, allowing you to remove it. Left-hand drill bits rotate counter-clockwise and can sometimes loosen a stuck fastener while drilling into it. They are useful for removing snapped studs or screws, as highlighted by products like the Sealey Left-Hand Spiral Drill Bit Set.

These sets are invaluable for removing stripped screws or snapped bolts, saving time and preventing further damage. They can turn a potential disaster into a manageable fix.

Choosing and Maintaining Your Investment

Selecting the perfect drill bit set is an investment that affects the quality of your work. Whether you’re a weekend warrior in Philadelphia or a professional contractor working across Southeastern PA, New Jersey, and Delaware, the right set will serve you well.

Project Assessment

Before buying, think about what you’ll actually be drilling. Don’t be impressed by a massive 115-piece set if you only need a dozen good bits.

Start with the material you’ll drill most often. For wood and plastic, a general-purpose HSS set is fine. For a stucco home, you’ll need carbide-tipped masonry bits that can handle the abrasive surface.

Think about hole sizes too. Most home projects use bits between 1/16″ and 1/2″. Also, make sure the shank type matches your drill. A hex shank is for an impact driver, while a round shank fits a standard chuck. SDS shanks are essential for hammer drills.

Benefits of a Set

Buying a complete drill bit set makes practical sense. Cost-wise, you’ll spend far less than purchasing individual bits. Organization is another key benefit. A good set comes in a case with designated spots for each bit, like DEWALT’s ToughCase® system, saving you from digging through a toolbox. Finally, having size variety on hand means fewer trips to the hardware store mid-project.

Maintenance Tips

Even the best drill bit set requires maintenance. A few simple habits will make your investment last.

After each use, wipe your bits down to remove dust and shavings. This prevents rust and buildup that can affect performance.

Always return bits to their case. Banging around loose in a drawer will dull or chip the delicate cutting edges. A proper case protects your investment.

Use the right bit for the job to maximize longevity. Forcing an HSS bit through concrete or using a masonry bit on wood causes unnecessary wear. When drilling metal, use cutting fluid to reduce heat and friction.

Know when to sharpen versus replace. HSS bits can be sharpened, but carbide-tipped bits are difficult to sharpen at home and are usually replaced when dull.

Watch for signs of a dull bit: slow drilling, needing excessive pressure, smoke, or rough holes. Forcing a dull bit is dangerous and damages your workpiece. A sharp bit should cut effortlessly. Stop and sharpen or replace a bit when you notice these symptoms.

Conclusion

This guide has covered the essentials of choosing a drill bit set, from materials and coatings to tip designs and set types. The right choice comes down to the materials you’ll be drilling, the features you need, and the scope of your projects. A homeowner in Wayne has different needs than someone building a deck in Wilmington or mounting fixtures on a property in Cherry Hill.

Think of a quality drill bit set as an investment that pays dividends by saving time, eliminating frustration, and delivering professional-looking results. A sharp, reliable set is a tool you’ll wonder how you ever managed without.

However, having the right drill bit is only half the equation with specialized materials like stucco. This common exterior finish in Southeastern Pennsylvania, New Jersey, and Delaware requires not just the proper carbide-tipped bit, but also an understanding of the material itself. Drilling into stucco incorrectly can lead to cracks, moisture intrusion, or structural damage.

Understanding the material is as critical as the tool. At Stucco Safe, we’ve spent years studying how stucco behaves and how to work with it without compromising its protective qualities. Our forensic testing methods and certified inspectors help property owners understand their stucco systems before problems develop.

When you’re ready to tackle your next stucco project, having the right information makes all the difference. To ensure you’re using the best tools and techniques for your home’s exterior, explore our comprehensive guide on the best drill bit for stucco. Your home’s exterior deserves the same care you put into selecting the right drill bit sets for every job.