Drill bits for hammer drill: Ultimate Guide 2025

Why Choosing the Right Drill Bits for Hammer Drill Projects Matters

Drill bits for hammer drill applications are specialized tools designed for tough materials like concrete, brick, and stucco. Using a regular drill bit won’t work; the hammering action requires bits built to withstand intense pounding while grinding through brittle surfaces.

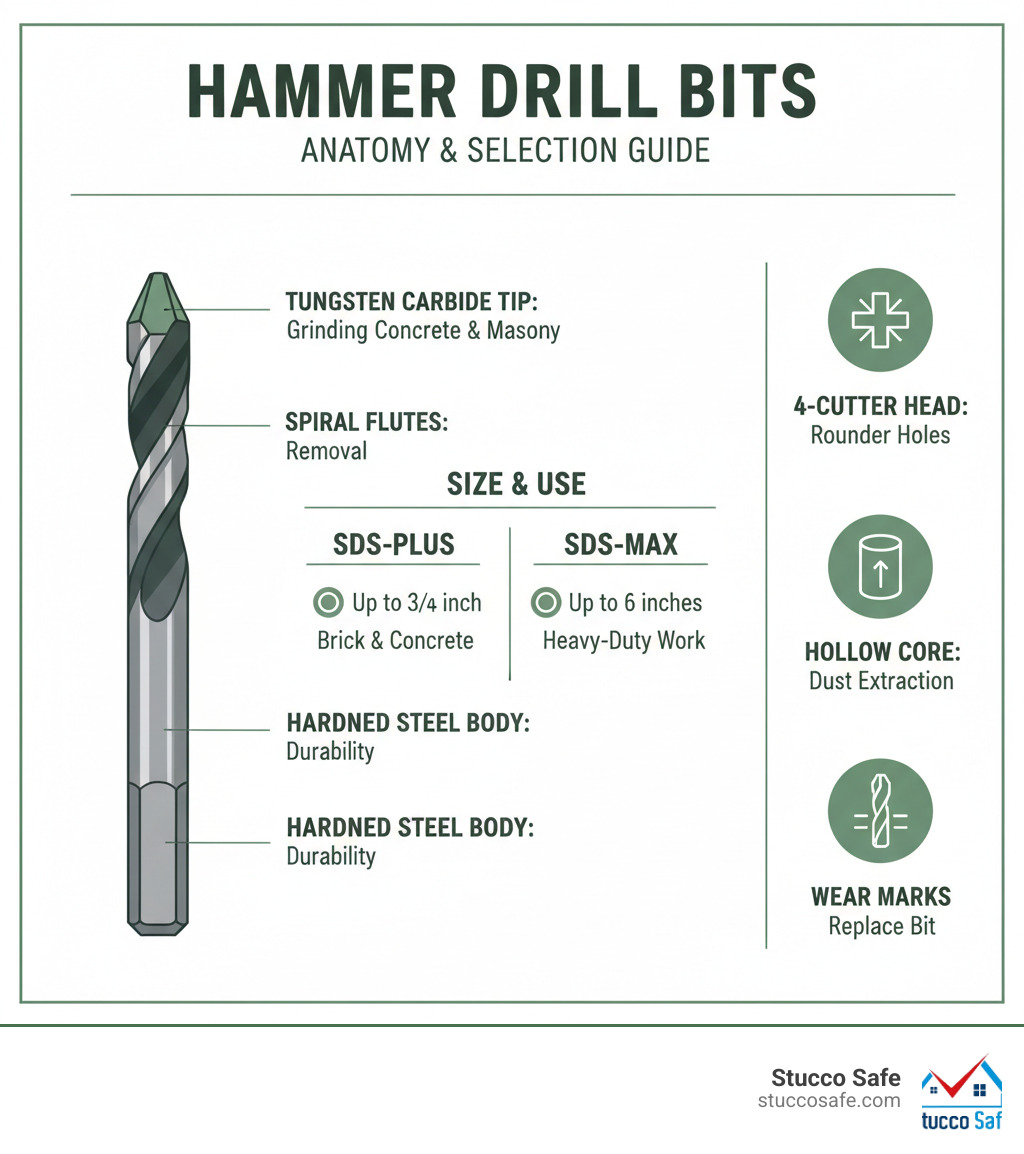

Quick Selection Guide:

- SDS-Plus bits – Standard choice for most concrete and masonry work (up to 3/4″ diameter)

- SDS-Max bits – Heavy-duty applications and larger holes (up to 6″ diameter)

- Carbide-tipped bits – Essential for concrete, brick, and stucco drilling

- 4-cutter head design – Creates rounder holes, better for precision work

- Hollow core bits – Best for dust-free drilling and OSHA compliance

These bits feature tungsten carbide tips on hardened steel shanks, with spiral flutes to clear debris. The wrong bit can lead to slow drilling, overheating, breakage, or damage to your home’s exterior. Whether you’re mounting a mailbox or installing anchors, using the right bit ensures a clean, professional result.

I’m Gabe Kesslick, and with two decades in building envelope inspection and stucco work, I’ve learned which drill bits for hammer drill applications perform best. This guide will help you select the right bit for your project, avoid common mistakes, and get the job done safely.

The Anatomy of a Hammer Drill Bit

Understanding how drill bits for hammer drill applications are built explains why they work so well on tough materials like concrete and brick, and why cheaper alternatives often fail.

Core Components and Materials

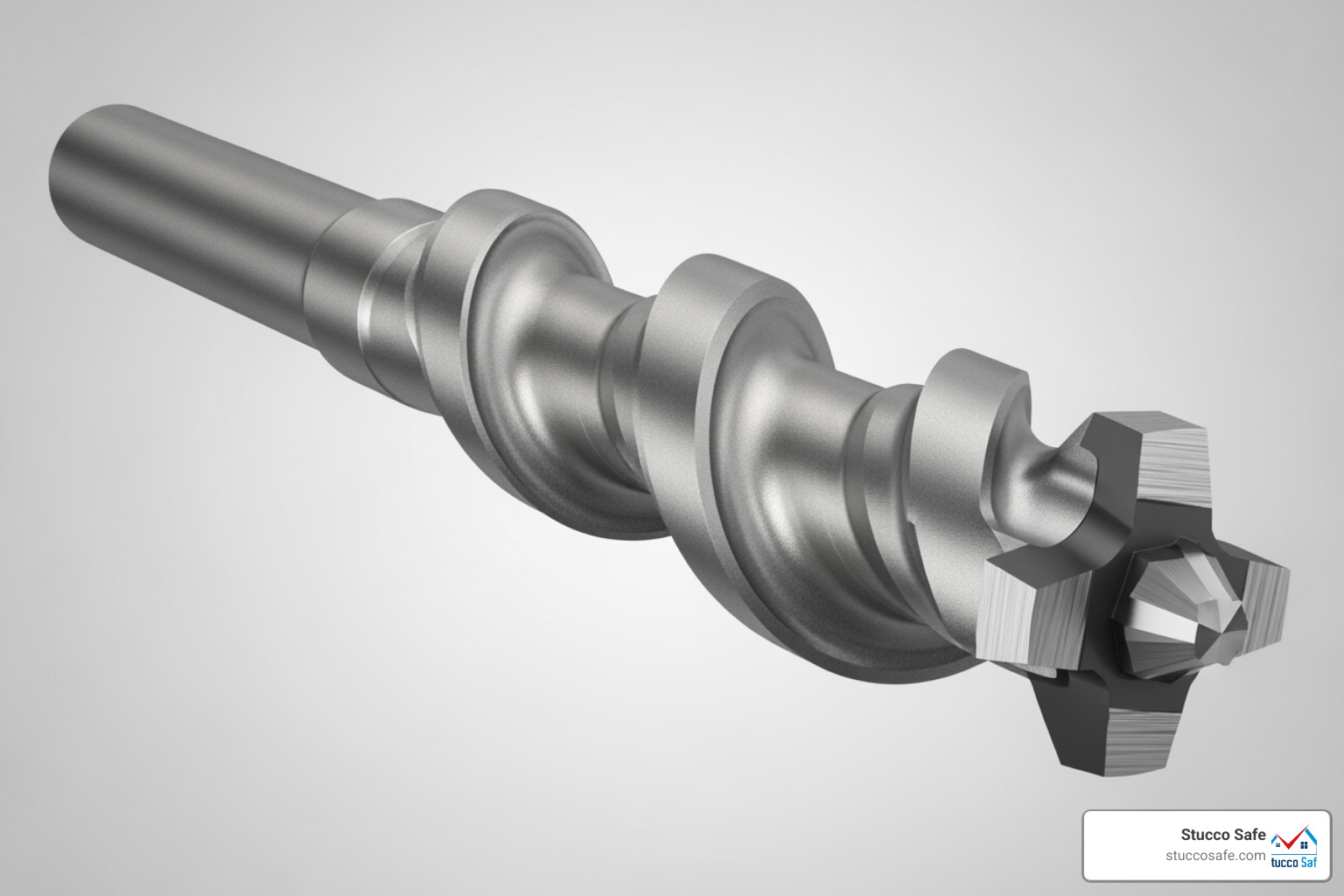

Every quality hammer drill bit has the same basic parts:

- Shank: Fits into the drill’s chuck, transferring both rotation and hammering force without slipping.

- Body: The main shaft, made from hardened steel to handle stress without bending or snapping.

- Flutes: Spiral grooves that act as a debris removal system, channeling dust and grit out of the hole to prevent clogging and overheating.

- Head and Tip: The business end where cutting happens. The tip is the secret weapon: it’s made of tungsten carbide.

This incredibly hard material is brazed onto the tip, providing remarkable durability, heat resistance, and hardness. It allows the bit to grind through abrasive masonry that would quickly dull regular steel. When I’m inspecting stucco homes and drilling test holes, I rely on carbide-tipped bits because they maintain their edge through multiple sessions.

How Design Dictates Performance

Subtle design choices separate average bits from exceptional ones. A well-engineered flute design, like a double spiral, efficiently removes dust and prevents overheating. When flutes get worn or packed, drilling speed drops.

The head design is a key differentiator. While traditional 2-cutter heads work, 4-cutter designs create rounder, more precise holes, which is critical for installing anchors. The four cutting edges also distribute impact more evenly, reducing vibration and extending bit life. Some premium bits feature full-carbide heads that can power through rebar without jamming.

Finally, tip geometry affects accuracy. Self-centering tips prevent the bit from wandering when you start a hole. High-temperature brazing ensures the carbide tip stays attached under intense hammering. These details explain why quality drill bits for hammer drill work cost more but pay off in faster drilling, cleaner holes, and longer-lasting tools.

A Guide to Different Drill Bits for Hammer Drill Models

Picking the right drill bits for hammer drill work means matching the bit to your drill model and the job. Understanding shank styles and specialized bits is crucial.

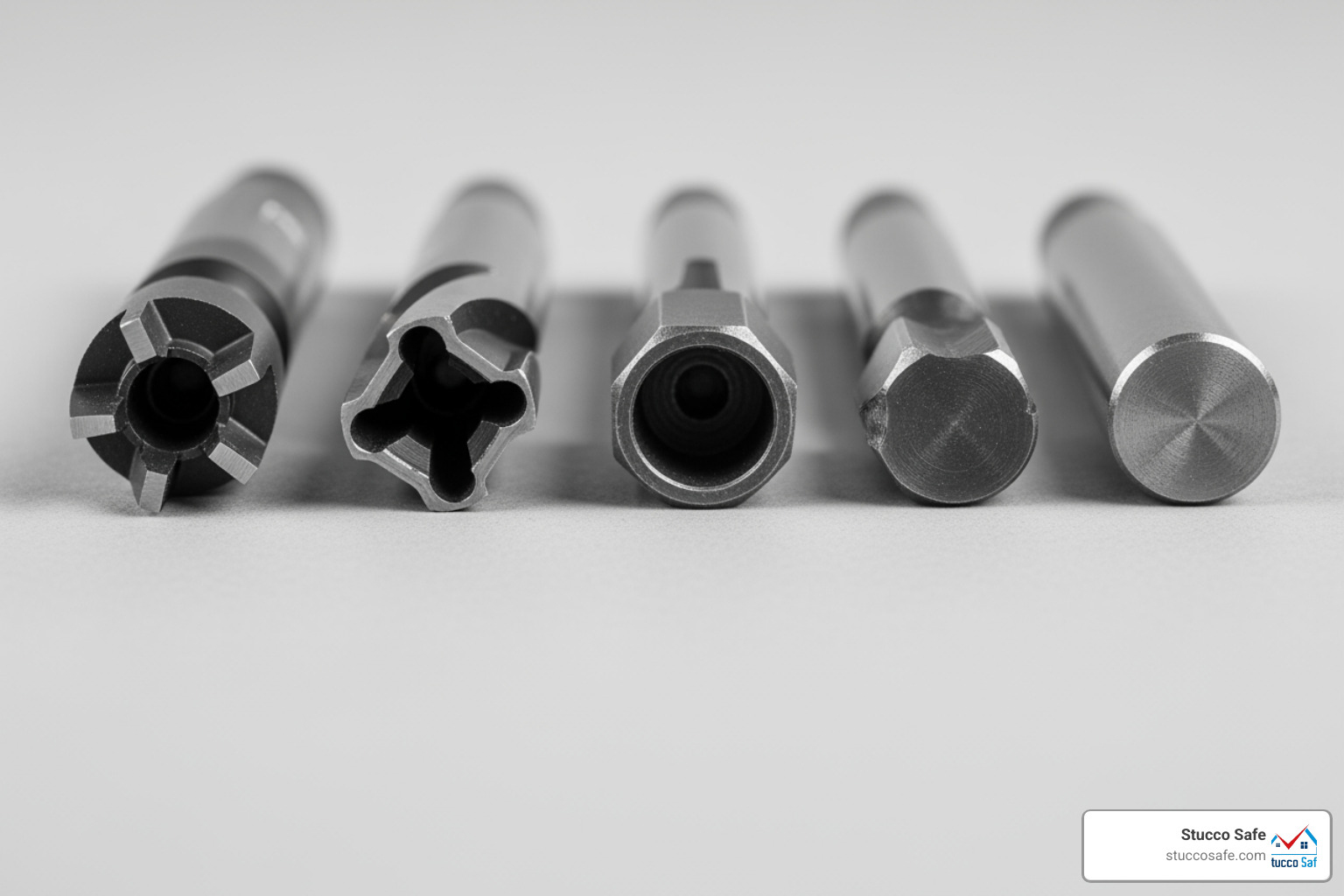

Understanding Shank Styles: SDS vs. Straight Shank

The shank connects the bit to the drill’s chuck, and the design dictates power transfer.

- Straight shanks are smooth and round, fitting traditional three-jaw chucks. They can be used for light-duty masonry drilling but tend to slip under heavy hammering loads.

- SDS (Slotted Drive System) shanks are the standard for hammer drills. Grooves on the shank lock into the chuck, preventing slippage and allowing the bit to move back and forth to amplify the hammering action.

There are two main SDS types:

- SDS-Plus: The workhorse for most homeowners and light commercial work. Ideal for drilling up to 3/4” diameter in concrete and masonry for tasks like installing anchors or brackets.

- SDS-Max: For heavy-duty applications. With a larger 18mm shank, these bits handle diameters up to 6” or more and are built for the high impact of professional rotary hammers used on reinforced concrete. A less common heavy-duty option is the Spline drive.

| Feature | SDS Plus | SDS Max |

|---|---|---|

| Chuck Size | Smaller, ~10mm diameter | Larger, ~18mm diameter |

| Bit Diameter Range | Up to 3/4″ (20mm) typically | Up to 6″ (150mm) or more |

| Common Applications | Light to medium concrete/masonry, anchor holes | Heavy-duty concrete, larger penetrations, rebar |

| Power Level | Moderate impact energy | High impact energy |

Specialized drill bits for hammer drill tasks

Beyond standard masonry and percussion bits for concrete, brick, and stone, several specialized bits exist:

- Rebar cutters: Designed to slice through steel reinforcement in concrete without jamming or breaking.

- Hollow core bits: Feature a hollow shaft for dust extraction, enabling virtually dust-free drilling. This is critical for silica dust safety (OSHA compliance) and creates cleaner holes for better anchor grip.

- Core bits: Drill large-diameter holes for pipes or conduits by removing a cylindrical core, which is much faster than grinding all the material.

- Stop bits: Have a collar to prevent over-drilling, ensuring precise hole depth for anchor installations.

- Chisel bits: For rotary hammers in chisel-only mode. Includes flat, point, and spade chisels for chipping, breaking, and demolition.

Buying Individually vs. in a Set

- Bit sets offer great value and convenience, providing a range of common sizes for general-purpose work. They are ideal for new users or those with varied projects.

- Individual bits are best for specific projects needing an uncommon size, for replacing a single worn bit, or when you need a high-performance specialty bit not found in sets.

A good strategy is to start with a quality set and buy individual specialty bits as needed. For more on bit construction, see this explanation of bit anatomy.

Matching the Bit to Your Project

The right drill bits for hammer drill work can mean the difference between a clean hole in seconds and a frustrating hour of overheating and breakage. It’s all about precision matching.

Selecting the Best Drill Bits for Hammer Drill Applications

Each material requires a specific bit for the best results.

- Standard Concrete: A carbide-tipped SDS-Plus bit is your workhorse. For precision anchor installations, upgrade to a 4-cutter head design for rounder, cleaner holes. Our article on Masonry Drill Bit for Concrete offers more detail.

- Brick, Block, and Stone: A quality carbide-tipped SDS-Plus bit (2-cutter or 4-cutter) will work well. Let the bit do the work; excessive pressure only generates heat.

- Reinforced Concrete: Hitting rebar with a standard bit can cause it to jam or break. Use heavy-duty SDS-Max bits with full-carbide heads, which are engineered to power through rebar without stopping.

- Stucco: This requires a balance of aggression and finesse to avoid cracking. Carbide-tipped masonry bits are effective, especially with proper technique. See our guides on the Best Drill Bit for Stucco and What Drill Bits Can I Use for Stucco for expert advice.

A 4-Step Selection Checklist

Before every drilling project, run through this quick mental checklist:

Step 1: Identify your drill’s chuck. Is it SDS-Plus, SDS-Max, or a standard chuck? The bit must match the chuck. Using adapters for hammer drilling is inefficient and risky.

Step 2: Define the material. Is it standard concrete, or could it be reinforced with rebar? Is brick backed by concrete block? Knowing what’s inside is critical for choosing the right bit.

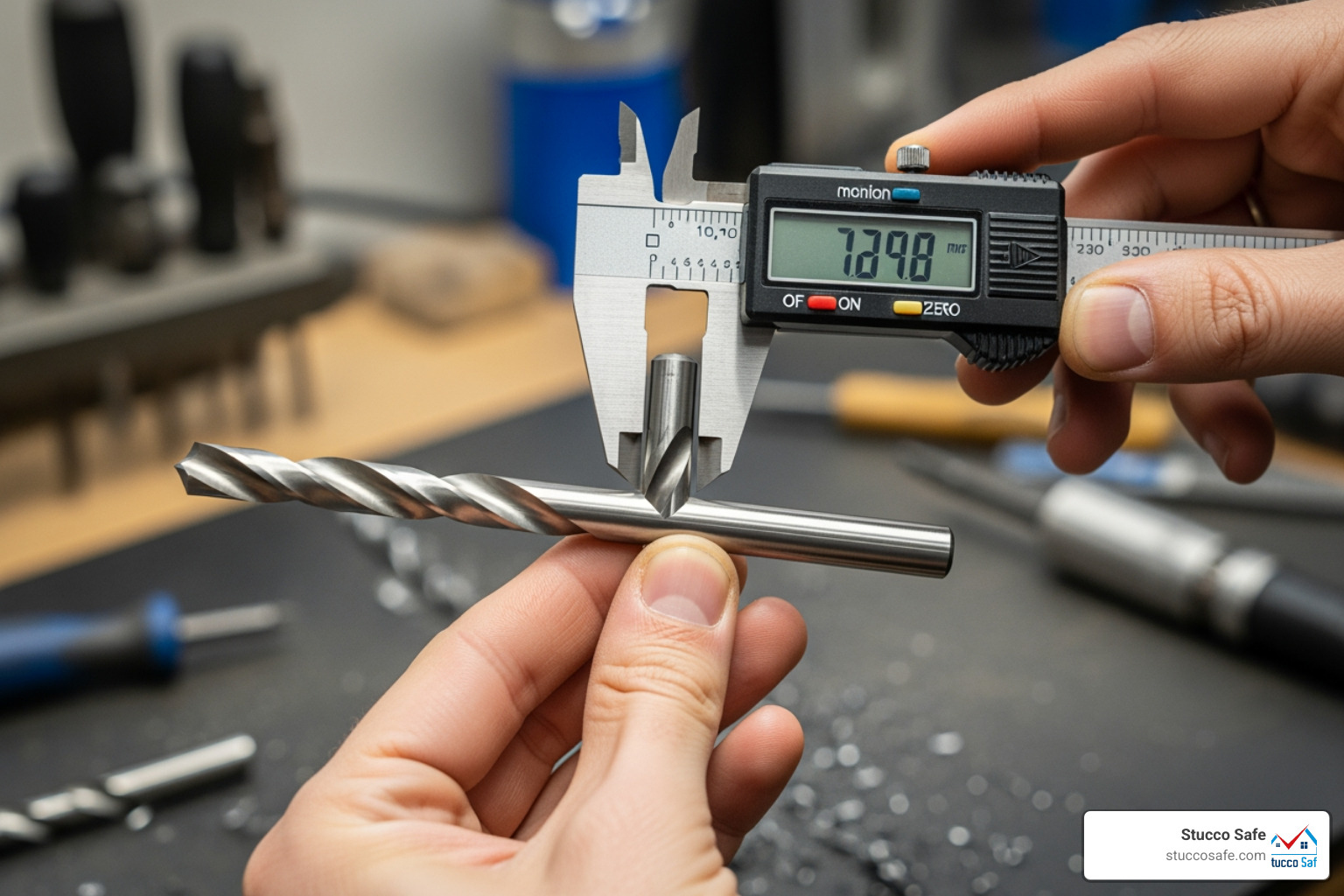

Step 3: Determine hole diameter and depth. For anchors, manufacturer specifications are not suggestions. A hole that is too large or shallow will compromise holding power. For precision, measure your bits with calipers.

Step 4: Choose the bit type and head design. Based on the steps above, you’ll know if you need a standard masonry bit, a rebar cutter, or a hollow core bit. For precision work or tough materials, consider a 4-cutter or full-carbide head.

This systematic approach to selecting drill bits for hammer drill applications saves time and prevents frustration, ensuring professional results, especially when drilling into exterior claddings like stucco.

Pro Tips for Usage, Safety, and Maintenance

Getting the most from your drill bits for hammer drill work involves correct usage, safety, and maintenance. A little care goes a long way in extending bit life and ensuring good results.

Troubleshooting Common Drilling Problems

- Bit Jamming: Usually caused by hitting rebar or clogged flutes. Back the bit out, clear the debris, and if you hit rebar, switch to a rebar-cutting bit.

- Overheating: Caused by pushing too hard or inefficient dust clearing. Ease up on the pressure, let the bit cool, and ensure flutes are clean.

- Slow Drilling: Often the first sign of a worn bit. Check the carbide tip for wear. A rounded tip needs replacement. Apply steady pressure and let the hammer action do the work.

- Bit Breakage: Typically from applying sideways pressure or using a worn-out bit. Always drill straight and inspect bits for cracks before use.

Dust Management and Safety

Drilling into concrete, brick, or stucco creates crystalline silica dust, a serious health hazard regulated by OSHA. Your lungs don’t care if you’re a pro or a DIYer.

Hollow drill bits connected to a vacuum or dust extractor are the best solution. They capture dust at the source, preventing it from becoming airborne. This not only protects your health but also creates cleaner holes, which improves anchor performance by providing a better gripping surface. For more on technique, see How to Drill into Stucco.

Always wear PPE: safety glasses, gloves, and at least a dust mask (a respirator is better for extensive work without dust extraction).

How to Maximize Your Drill Bit’s Lifespan

Quality drill bits for hammer drill applications are an investment. Proper care extends their life significantly.

- Proper Storage: Keep bits in a clean, dry case to prevent rust and damage.

- Correct Drill Settings: Use hammer mode only for masonry. Match the RPM to the bit size and material to avoid overheating.

- Clean After Use: Wipe down bits to remove dust from the flutes. This prevents buildup and allows for inspection. The HB2X SDS Plus Hammer Drill Bit is an example of robust construction.

- Recognize Wear: Replace bits when you notice slow drilling, overheating, or a visibly rounded carbide tip. Many quality bits have wear marks; once the tip wears past this mark, the bit will no longer drill an accurately sized hole for anchors. When performance drops, replace the bit.

Frequently Asked Questions about Hammer Drill Bits

Here are answers to the most common questions we get about drill bits for hammer drill applications.

Can I use a hammer drill bit in a regular drill?

Generally, no. There are two main reasons:

- Shank Incompatibility: Most dedicated hammer drill bits (SDS-Plus, SDS-Max) have specialized shanks that will not fit in a regular drill’s three-jaw chuck.

- Lack of Hammer Action: Even if you have a straight-shank masonry bit that fits, a regular drill only spins. It lacks the percussive impact needed to pulverize concrete or brick. Using it will be painfully slow, inefficient, and will quickly dull the bit.

For hard materials, you need the combination of rotation and impact that only a hammer drill can provide.

What’s the difference between a hammer drill bit and a standard masonry bit?

While the terms are often used interchangeably, there’s a key distinction. A standard masonry bit is any bit with a carbide tip for drilling into materials like brick or concrete. A hammer drill bit is a type of masonry bit specifically built to withstand the intense pounding of a hammer drill or rotary hammer.

The main differences are shank design (SDS shanks offer superior power transfer for hammer drills) and overall impact durability. Hammer drill bits are reinforced to handle thousands of impacts without failing. Our article on Cement Drill Bit explores this further.

How do I know when to replace my hammer drill bit?

Knowing when to retire a bit is key for efficiency and accuracy. Look for these signs:

- Slower Drilling: If a hole takes much longer to drill than it used to, the bit is likely dull.

- Excessive Heat: A dull bit creates more friction and heat. If your bit is smoking or discolored, it’s overworked.

- Worn Carbide Tip: Inspect the tip. If the cutting edges are rounded, chipped, or gone, it’s time for a replacement.

- Wear Marks: Many high-quality SDS bits have manufacturer wear marks on the tip. If the bit has worn past this mark, it will no longer drill an accurately sized hole, which is critical for anchor installations.

Inspect your drill bits for hammer drill tasks regularly. A quick check can prevent inaccurate holes and compromised anchor performance.

Conclusion

Choosing the right drill bits for hammer drill applications is the key to a successful project when working with concrete, brick, or stucco. As we’ve covered, success comes down to a few core principles.

First, understand the anatomy: tungsten carbide tips provide the hardness, while features like 4-cutter heads and efficient flutes deliver precision and speed. Second, match your bit to both your drill and your material. An SDS-Plus bit is great for general masonry, but reinforced concrete demands a heavy-duty SDS-Max bit with a rebar-cutting head. For stucco, precision is paramount to prevent cracking.

Investing in quality bits pays off in faster work, cleaner holes, and longer tool life. A worn or incorrect bit can compromise anchor strength and damage your home’s exterior.

Finally, always prioritize safety and maintenance. Managing silica dust with hollow core bits and vacuum attachments is essential for your health and for creating strong anchor points. Proper storage, cleaning, and knowing when to replace a worn bit will save you money and frustration.

At Stucco Safe, this level of precision is part of our daily work across Southeastern Pennsylvania, New Jersey, and Delaware. Our forensic stucco inspections require us to drill accurate test holes without compromising the home’s integrity. This expertise ensures we provide reliable results that protect homeowners from hidden moisture and structural problems. For more on our methods, see the Best Way to Drill into Stucco.

Whether you’re a homeowner or a contractor, using the right tools and techniques empowers you to work smarter and achieve professional results.

Ready to learn more about stucco-specific drilling? Learn more about the best drill bits for your stucco project and see how the right approach makes all the difference.