Heavy Duty Toggle Bolts: #1 Ultimate Solution

The Ultimate Solution for Hollow Wall Fastening

Heavy duty toggle bolts are specialized fasteners for securely mounting items to hollow walls like drywall or plaster. They expand behind the wall to distribute weight over a large area, providing exceptional holding power. Modern designs offer twice the capacity of traditional wing toggles while requiring a 50% smaller installation hole.

Top Heavy-Duty Toggle Bolt Options:

| Feature | Snaptoggle | Traditional Wing Toggle | Self-Drilling Anchor |

|---|---|---|---|

| Load Capacity | Up to 265 lbs (1/2″ drywall) | Up to 130 lbs | Up to 100 lbs |

| Installation Hole | 1/2″ for 1/4″ bolt | 3/4″ for 1/4″ bolt | 3/8″ |

| Reusable | Yes | No | No |

| Installation Time | Fast (6 min saved) | Slow | Fastest |

Key advantages include metal-to-metal fastening that resists vibration, a non-spinning design for single-person installation, and a reusable anchor that stays in the wall if the bolt is removed. Whether mounting a TV, grab bars, or heavy shelving, the right toggle bolt ensures a secure installation.

I’m Gabe Kesslick, and as an EDI Level 2 Certified Stucco Inspector and BESI Certified Building Envelope Forensic Inspector, I’ve seen countless fastener failures. Heavy duty toggle bolts are my essential recommendation for secure, long-lasting installations in hollow walls. Understanding the right anchor for your wall material can prevent costly repairs and safety hazards.

Understanding Heavy-Duty Toggle Bolts and Their Superior Strength

When hanging a heavy mirror or flat-screen TV, you can’t always rely on finding a wall stud. This is where heavy duty toggle bolts excel, offering a significant leap in design and strength over standard anchors.

Traditional toggle bolts, or “wing toggles,” use a spring-loaded wing that opens behind the wall. They work for light items but have limited load capacity, and the wing is lost inside the wall if you remove the bolt. Installation can also be awkward.

Heavy duty toggle bolts are engineered differently to handle much greater weight—often up to twice the load of traditional wing anchors. This strength comes from a solid metal channel that expands behind the wall, creating a robust metal-to-metal connection that resists shock and vibration.

What Makes a Toggle Bolt “Heavy-Duty”?

The “heavy-duty” label signifies key design innovations:

- Superior Load Capacity: A heavy-duty toggle can hold up to 265 lbs in 1/2″ drywall, compared to about 130 lbs for a traditional wing toggle. This comes from the solid metal channel and a more sophisticated locking mechanism.

- Smaller Installation Hole: A 1/4-inch heavy-duty toggle requires only a 1/2-inch hole, 50% smaller than the 3/4-inch hole needed for a wing toggle of the same size. This preserves your wall’s integrity, which is especially important in plaster or stucco.

- Metal-to-Metal Fastening: The bolt threads directly into the metal channel, creating an exceptionally strong connection that resists pull-out forces and shear stress.

- Modern Strap Design: High-impact polystyrene straps allow for precise adjustment so the anchor sits flush against the back of the wall. They snap off cleanly, leaving the anchor in place for reuse.

Key Benefits Over Traditional Anchors

The advantages of modern heavy-duty toggles make them a superior choice for demanding applications:

- Faster, Easier Installation: The anchor won’t spin as you tighten the bolt, allowing for quick, one-person installation with a screw gun. This can save up to six minutes per anchor.

- Reusable Anchor: The anchor channel stays in the wall when the bolt is removed. This is ideal for items you may need to take down for painting or cleaning.

- Preserves Wall Integrity: The smaller hole size means less damage to your wall, preventing cracks and maintaining structural strength.

These design improvements result in significant time and cost savings, whether you’re a professional contractor or a DIYer. For more detailed information on different anchor types, check out our guide on anchor types. You can also explore the technical specifications of modern toggle bolts to see how they achieve their impressive strength ratings.

How to Choose the Right Heavy-Duty Toggle Bolt

Picking the perfect heavy duty toggle bolt is critical to prevent mounting failures. To get it right, you need to assess your project’s specific needs: what you’re mounting, its weight, the wall material, and the environmental conditions (e.g., a humid bathroom vs. a dry living room).

Material Matters: Zinc vs. Stainless Steel

- Zinc-Plated Steel: This is the cost-effective workhorse for most dry, indoor applications like mounting a TV or shelves. Modern zinc plating offers good corrosion resistance for climate-controlled spaces.

- Stainless Steel: This is essential for high-moisture or exterior environments. Use Type 304 stainless steel for grab bars in showers, outdoor fixtures, or in coastal areas like those we serve in New Jersey and Delaware. The upfront cost is higher, but it prevents rust and anchor failure.

For interior work, zinc-plated steel is usually sufficient. For any exterior or damp applications, especially on stucco, we recommend stainless steel. Our guide on Best Anchors for Stucco offers more detailed advice.

Sizing for Success: Matching the Bolt to the Load

Proper sizing ensures a secure installation. Consider these factors:

- Bolt Diameter: Larger diameters (e.g., 3/8-inch vs. 1/4-inch) support heavier loads.

- Bolt Length: The bolt must pass through your fixture and the wall, with enough length left to fully engage the toggle. A good rule is: Fixture Thickness + Wall Thickness + 1/2 inch.

- Weight Capacity: Manufacturers provide ultimate test loads, but you should never load an anchor to its maximum capacity. Always apply a 4:1 safety factor—use only one-quarter of the ultimate rated load. For an anchor rated at 265 lbs, the safe working load is about 66 lbs. This accounts for real-world variables and ensures long-term safety.

Comparing Heavy-Duty Toggle Bolts to Other Anchors

- Heavy-Duty Toggle Bolts: The strongest option for hollow walls (up to 265 lbs in drywall). Best for heavy, critical items like TVs and grab bars. They are reusable and offer the highest reliability.

- Molly Bolts (Sleeve Anchors): A good mid-range choice for medium-weight items (50-75 lbs). The sleeve remains in the wall, so they are reusable. They offer less holding power than heavy-duty toggles.

- Self-Drilling Anchors: The fastest option for light-duty jobs (25-50 lbs) like hanging pictures. They screw directly into drywall but are not reusable and offer the lowest strength.

Step-by-Step Installation Guide

Installing modern strap-type heavy duty toggle bolts is a straightforward process that can usually be done by one person. Proper preparation is the key to a successful, rock-solid installation.

Preparing for Installation

Before you drill, complete these essential prep steps:

- Mark the Location: Use a pencil and a level to mark the exact mounting point. Double-check your measurements.

- Check for Clearance: The toggle needs space to expand. Most strap-type toggles require a minimum clearance of 1 7/8 inches behind the wall. Drill a small pilot hole to check for obstructions like pipes or studs.

- Identify Obstacles: Use a stud finder to locate any hidden wiring, plumbing, or framing. This is especially important in older homes like those found throughout Southeastern Pennsylvania.

- Gather Tools: Have your drill, the correct drill bit (e.g., 1/2-inch for a 1/4-inch toggle), a screwdriver or screw gun, a level, and safety glasses ready.

- Consider Wall Material: Use a standard bit for drywall but switch to a masonry bit for plaster or stucco. For detailed guidance, see our guide on the Best Way to Drill into Stucco.

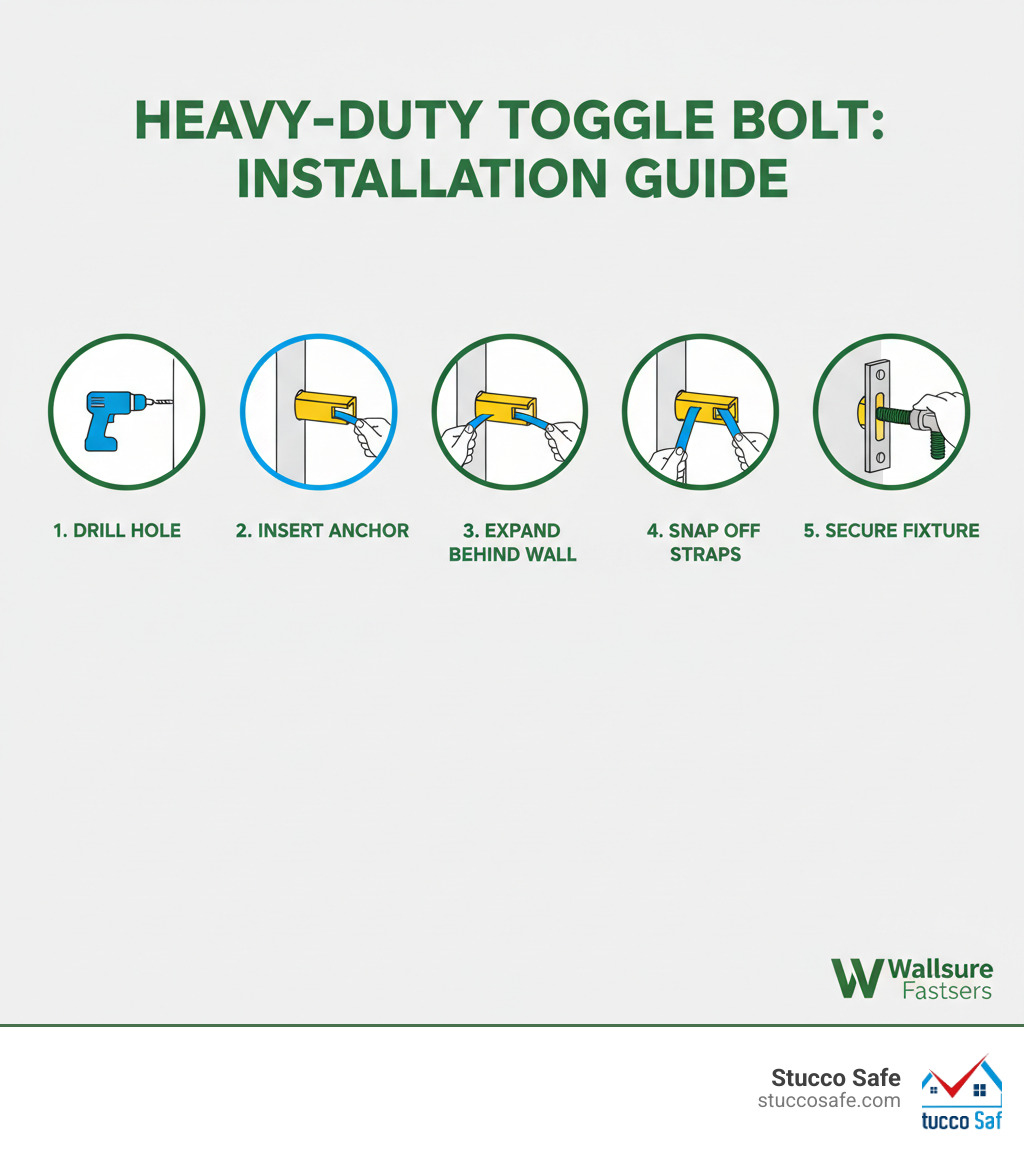

Installing a Strap-Type Toggle Bolt

With your prep work done, follow these steps for a perfect installation:

- Drill the Hole: Drill a clean hole at your marked location using the manufacturer-specified drill bit size. Keep the drill perpendicular to the wall.

- Insert the Metal Channel: Fold the metal channel flat against the plastic straps and push the entire assembly through the hole until the channel is completely inside the wall cavity.

- Set the Anchor: Pull the straps firmly toward you. This will pivot the metal channel so it sits flat against the back of the wall.

- Position the Cap: While pulling on the straps, slide the plastic cap down until its flange is flush with the wall surface.

- Snap Off the Straps: Push the straps side-to-side at the wall surface until they snap off cleanly, leaving the anchor installed.

- Mount Your Fixture: Position your item over the installed cap, insert the bolt through your fixture, and thread it into the metal channel.

- Tighten the Bolt: Use a screwdriver or screw gun to tighten the bolt until it is snug. The anchor is designed not to spin. Do not overtighten, as this can damage the drywall.

Common Applications: From Home DIY to Commercial Construction

The versatility of heavy duty toggle bolts makes them a go-to solution for securing heavy items to hollow walls in both residential and commercial settings.

Residential Projects

In homes, these fasteners give you the freedom to mount heavy items securely without being limited by stud locations. Common uses include:

- Flat-screen TVs: Especially large models or those on articulating mounts.

- Heavy mirrors and artwork: Providing peace of mind that valuable decor stays put.

- Grab bars and towel racks: Essential for safety in bathrooms, where anchors must withstand significant force. Stainless steel versions are ideal here.

- Kitchen cabinets and heavy shelving: For supplemental support or mounting units where studs aren’t available.

- Handrails and window accessories: Securing stair railings and heavy curtain rods that are subject to pulling forces.

Commercial and Industrial Uses

In commercial settings, where loads are heavier and safety stakes are higher, heavy duty toggle bolts are indispensable. Applications include:

- Office furniture and partitions: Anchoring modular systems and heavy filing units to prevent tipping.

- Commercial shelving: Supporting heavy inventory in retail spaces and warehouses.

- Heavy machinery and equipment: Mounting large ceiling fans or equipment that creates vibration, where the metal-to-metal fastening excels.

- Solar panels and mounting systems: Securing support brackets and conduit to exterior walls. For critical exterior jobs, consult our Stucco Anchoring Ultimate Guide.

Suitable Wall Materials

Heavy-duty toggle bolts are adaptable to a wide range of hollow wall materials:

- Drywall (Gypsum Board): The most common application, where the toggle spreads the load across the back of the panel.

- Plaster and Lath: Works well in older homes, with the toggle expanding behind the lath strips.

- Concrete Block (CMU): Ideal for hollow block walls, where these anchors can achieve their highest load ratings.

- Tile over Drywall/Cement Board: After carefully drilling through the tile, the toggle provides a strong anchor point in the hollow space behind.

- Stucco: These anchors can work in stucco walls, but proper installation is critical to maintain the building’s weather-resistant envelope. Any penetration creates a potential path for moisture intrusion, which can lead to rot and costly repairs. Before drilling into stucco, we recommend understanding the wall assembly. Our guide on How to Install Anchors in Stucco provides techniques for a watertight installation.

Frequently Asked Questions about Heavy-Duty Toggle Bolts

Here are answers to some of the most common questions about heavy duty toggle bolts.

How much weight can a heavy-duty toggle bolt actually hold?

The holding strength depends on the bolt size and the wall material (substrate). For example, a 1/4-inch strap-style toggle bolt can hold around 265 lbs in 1/2-inch drywall but over 800 lbs in a concrete block.

Crucially, always use a 4:1 safety factor. This industry standard means you should only apply 1/4 of the manufacturer’s ultimate rated load. For an anchor rated at 265 lbs, your safe working load is about 66 lbs. This conservative approach accounts for real-world variables and ensures long-term safety.

Can you reuse a heavy-duty toggle bolt?

It depends on the type:

- Traditional Wing Toggles: No. When you remove the bolt, the spring-loaded wings fall into the wall cavity, and the anchor is lost.

- Modern Strap-Type Toggles: Yes. The metal anchor channel remains securely behind the wall when the bolt is removed. This allows you to take down and re-hang items as needed, offering great convenience.

What is the biggest mistake when installing toggle bolts?

Two common errors can compromise an anchor’s strength:

- Drilling the Wrong Size Hole: A hole that is too small prevents insertion. A hole that is too large prevents the anchor from seating properly, drastically reducing its holding power. Always use the exact drill bit size specified by the manufacturer.

- Insufficient Clearance Behind the Wall: The toggle mechanism needs space to open. Most heavy-duty toggles require a minimum clearance of 1 7/8 inches. If an obstruction is in the way, the anchor will not engage correctly and will fail under load. Always check for clearance before drilling the final hole.

Conclusion: Fasten with Confidence

Heavy duty toggle bolts are a superior solution for mounting projects in hollow walls, offering reliability and strength where studs aren’t available. They provide up to twice the holding power of traditional anchors with a 50% smaller installation hole, translating directly into safer, more durable installations.

Whether you’re a DIYer or a professional, these fasteners adapt to your needs. The choice between zinc-plated steel for indoor use and stainless steel for wet or outdoor areas provides flexibility, while features like reusability and a non-spinning design save time and effort. By choosing the right size and installing it correctly, you can be confident your mounted items will remain secure.

A word about exterior installations: When working on exterior walls, especially stucco, protecting your home’s moisture barrier is paramount. A poorly sealed anchor can allow water infiltration, leading to hidden rot and expensive repairs. Before drilling into stucco, consider a professional evaluation. At Stucco Safe, our certified inspectors in Southeastern Pennsylvania, New Jersey, and Delaware use forensic methods to assess your wall’s condition and recommend the safest approach. Our Stucco Wall Anchors Complete Guide offers more insight into best practices.

When you’re ready to purchase, you can find quality heavy duty toggle bolts at major retailers like The Home Depot or from specialized suppliers like FMW Fasteners. Always check product specifications to ensure you’re getting the right anchor for your job. With the right knowledge and a careful approach, you can fasten with complete confidence.