Industrial Inspection and Analysis: Ultimate Guide 2025

What is Industrial Inspection & Analysis (IIA)?

Industrial inspection and analysis (IIA) is a vital process for ensuring the safety and reliability of industrial equipment, structures, and systems. It’s a thorough health check for large-scale operations.

Here’s a quick overview:

- What it is: A systematic evaluation of industrial assets to ensure their integrity, safety, and performance.

- Core Mission: To prevent failures, reduce risks, and maintain compliance with industry standards and regulations.

- Key Services: This field includes Non-Destructive Testing (NDT), laboratory analysis, engineering solutions, and certified lifting equipment inspections.

- Who uses it: Industries from power generation and oil & gas to aerospace and critical infrastructure rely on IIA.

IIA protects valuable assets, workers, and the public. Without it, the risk of costly breakdowns, environmental harm, or serious accidents increases dramatically.

My career in structural integrity began in 2001 with leak detection and repair. This led me to found Stucco Safe, where we apply the principles of IIA to residential and commercial building envelopes, using forensic testing methods for stucco and moisture.

The Core Services: A Spectrum of Technical Expertise

Industrial inspection and analysis comprises a suite of services designed to keep operations running safely and efficiently. The goal is to prevent problems, ensure compliance, and extend the life of valuable assets.

Non-Destructive Testing (NDT) and Examination (NDE)

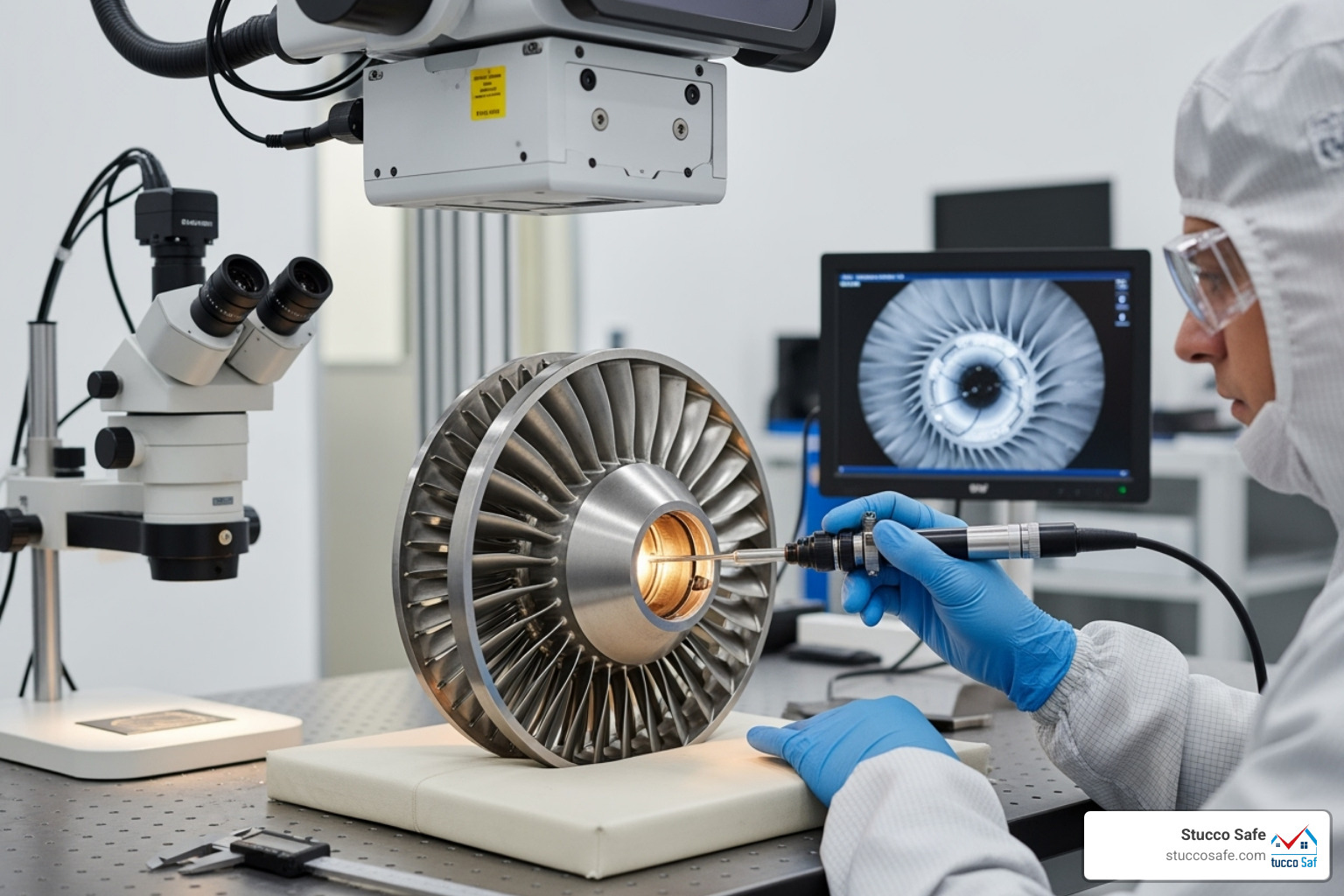

Non-Destructive Testing (NDT), or Non-Destructive Examination (NDE), allows for the inspection of materials and components for hidden flaws without causing damage. It is essential for assets ranging from pipelines to aircraft parts. With over 45 years of collective experience, we understand a wide range of NDT methods:

- Visual Inspection (VT): The first step in many inspections, where a trained eye identifies surface issues like corrosion or wear.

- Ultrasonic Testing (UT): Uses high-frequency sound waves to find internal flaws, measure material thickness, and check welds. Advanced methods like Phased Array Ultrasonic Testing (PAUT) provide more detailed images.

- Magnetic Particle Inspection (MPI): For magnetic metal parts, this method uses magnetic fields and fine particles to reveal surface and near-surface cracks.

- Radiographic Testing (RT): Similar to medical X-rays, RT uses X-rays or gamma rays to create an image of a material’s interior, revealing voids or cracks.

- Liquid Penetrant Inspection (DPI): Finds tiny surface cracks in non-porous materials. A special liquid seeps into flaws, which are then made visible by a developer.

- Eddy Current Testing (ET): Uses electromagnetism to find surface and near-surface flaws in conductive materials, often used for pipes or aircraft parts.

These techniques are critical for ensuring industrial assets are structurally sound. At Stucco Safe, we apply similar principles of detailed inspection to protect your home’s exterior. Learn more in our insights on building envelope inspection services.

Laboratory and Material Analysis

When visual inspection isn’t enough, laboratory and material analysis provides a deeper understanding of a material’s composition, strength, and behavior.

Our lab services include:

- Destructive Testing (DT): Unlike NDT, DT tests a sample to failure to determine its tensile strength, hardness, or impact resistance.

- Metallurgical Testing: Examines the physical and chemical properties of metals to understand material degradation, failure modes, and material selection.

- Chemical Analysis: Identifies the elemental and molecular composition of a material.

- Environmental Testing: Assesses how materials perform under harsh conditions like extreme temperatures, humidity, or corrosive environments.

- Fuel Analysis: Regular testing of fuels, oils, and coolants is vital for machinery maintenance. It identifies contaminants and ensures quality according to ASTM standards.

- Forensic Testing Methods: When a failure occurs, forensic analysis identifies the root cause. Our certified moisture testing for building exteriors uses these methods to diagnose issues. Learn more about certified moisture testing.

Engineering and Forensic Investigation

Engineering and forensic investigation teams determine why a problem occurred, how to fix it, and how to prevent it from happening again.

Our engineering services help with:

- Failure Analysis: When a component fails, engineers investigate the root cause, whether it’s material fatigue, a design flaw, or operational error.

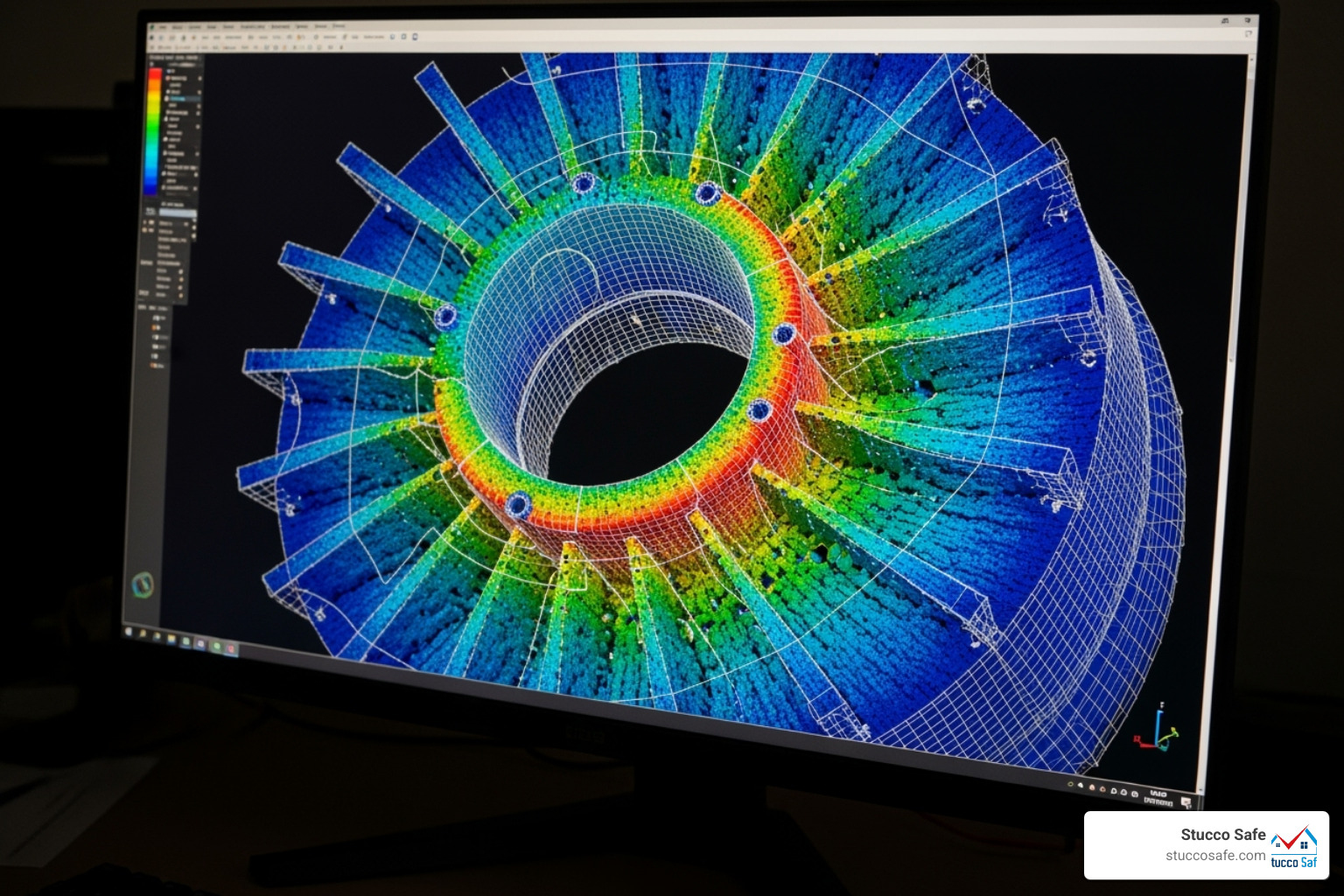

- 3D Laser Scanning and Metrology: This technology creates precise digital models of components or structures for detailed inspection, quality control, and reverse engineering (scan to CAD).

- Design Challenges and Solutions: Engineers provide solutions for complex quality and design issues, ensuring projects meet the highest safety and performance standards.

- Litigation Support: In legal disputes, forensic engineers provide objective analysis and expert testimony. Our experience with forensic building inspections provides similar fact-based support in property lawsuits.

These advanced engineering principles are also vital in emerging fields like the Additive Manufacturing Center of Excellence (AM COE) for testing new materials.

Specialized and Lifting Services

Some jobs require specialized skills, particularly for hard-to-reach areas and critical lifting equipment, where failure can be catastrophic.

Our specialized services include:

- Lifting Equipment Inspection: All lifting devices, from cranes to aerial work platforms, require regular certified inspections to meet safety regulations and prevent accidents.

- Aerial Device Inspection: Bucket trucks and other aerial devices used in utility and fire services undergo rigorous inspections to ensure structural integrity.

- Fire Apparatus Testing: We help fire departments maintain readiness by testing hoses, pumps, and ladders to ensure they meet NFPA standards. In 2023, U.S. fire departments responded to a fire every 23 seconds on average, highlighting the need for reliable equipment.

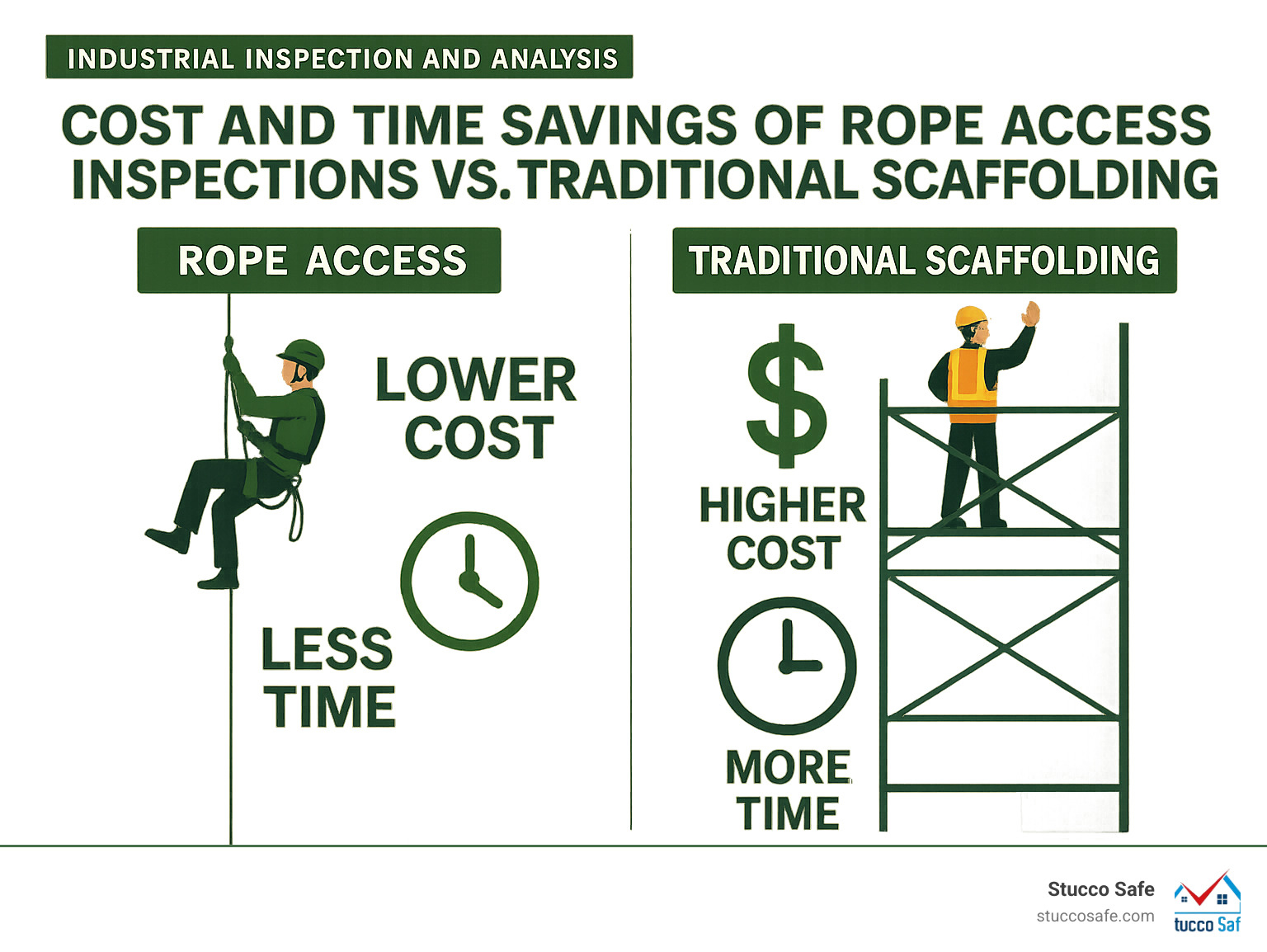

- Rope Access Inspection: For structures like bridges, wind turbines, or offshore platforms, rope access is a safe and efficient inspection method. Trained technicians rappel down structures, saving 30% to 80% in costs compared to traditional methods like scaffolding.

Here’s a quick look at the benefits of rope access:

These services ensure that even the most complex industrial operations can proceed with confidence. Common equipment requiring certified inspections includes:

- Cranes (overhead, gantry, mobile)

- Forklifts and material handling equipment

- Aerial work platforms (AWPs) and boom lifts

- Slings, shackles, and rigging hardware

- Hoists and winches

- Spreader beams and lifting frames

- Man-baskets and personnel platforms

- Fire truck ladders and aerial devices

- Fall protection systems

Key Industries Reliant on Industrial Inspection and Analysis

Nearly every major industry relies on industrial inspection and analysis to maintain asset integrity, public safety, and economic viability. It is the backbone of modern industrial operations.

Energy and Utilities

The energy sector’s massive infrastructure demands constant inspection to prevent devastating failures.

- Power generation facilities, including fossil fuel, nuclear, and renewable energy sources like wind turbines, require constant vigilance. Inspections cover critical components like turbines, generators, boilers, and high-energy piping to ensure efficiency and prevent breakdowns.

- The Oil and Gas industry relies on rigorous inspection from exploration to refining. NDE methods are critical for managing the integrity of pipelines, storage tanks, and pressure vessels. This extends to the Midstream sector, where pipeline integrity programs ensure the safe transport of resources.

- Even basic utilities like drinking water systems require stringent checks to comply with regulations like the EPA’s Lead and Copper Rule Improvements (LCRI), protecting public health. Our work at Stucco Safe in addressing moisture intrusion detection shares the core principle of protecting essential systems from environmental damage.

Manufacturing and Aerospace

In industries where precision is critical, industrial inspection and analysis is integral to production.

- For precision manufacturing of items like automotive parts or firearms components, services like dimensional inspection and CT scanning verify that products meet exact specifications.

- As Additive Manufacturing (3D printing) becomes more common, specialized inspection is needed. The Additive Manufacturing Center of Excellence (AM COE) highlights the importance of testing these novel materials and parts.

- The aerospace industry demands the highest levels of safety. Inspections cover everything from ground support equipment to aircraft components. Companies often hold FAA Repair Station certifications and NADCAP accreditation, demonstrating a commitment to rigorous quality standards.

Infrastructure and Commercial Buildings

Our daily lives depend on a vast network of infrastructure that requires regular inspection to ensure longevity and safety.

- Critical structures like bridges and towers are constantly exposed to the elements. Rope access inspections offer a cost-effective way to evaluate their structural integrity. Similarly, storage tanks require regular checks for corrosion and leaks to prevent environmental contamination.

- The integrity of commercial properties and building envelopes is also vital. The building envelope—the roof, walls, windows, and foundations—protects the interior. At Stucco Safe, we apply our expertise in forensic testing methods to Commercial Stucco and EIFS Inspections, identifying latent defects. To understand how we uncover hidden problems, explore our approach to forensic stucco testing. For residential properties, stucco inspections typically range from $495 to $1595 or more for very large homes, reflecting the thoroughness required.

The Pillars of Modern Inspection: Technology, Safety, and Compliance

The field of industrial inspection and analysis is constantly evolving, driven by new technologies and an unwavering commitment to safety and compliance. Innovation is essential for performing inspections correctly and efficiently.

The Role of Advanced Technology in Industrial Inspection and Analysis

Technology is revolutionizing how inspections are performed, making them safer, more efficient, and more accurate.

- Rope Access Techniques are a game-changer for inspecting hard-to-reach structures. Instead of costly scaffolding, trained technicians can rappel down a structure, saving customers 30-80% and minimizing operational downtime.

- Drone Inspections, equipped with high-resolution and thermal cameras, can quickly survey large areas like solar farms or wind turbines, reducing risk to human inspectors.

- Robotic Crawlers are invaluable for inspecting hazardous environments like the inside of pipelines or storage tanks, collecting data without endangering human teams.

- Advanced NDE (Non-Destructive Examination) Methods like Pulsed Eddy Current (PEC) can detect corrosion under insulation, while Guided Wave Testing (GWT) can inspect long sections of pipe from a single point.

- 3D Laser Scanning provides highly precise dimensional data, which is crucial for quality control, reverse engineering, and assessing structural deformation.

To give you a clearer picture, here’s a quick comparison highlighting the impressive benefits of rope access:

| Feature | Rope Access | Traditional Scaffolding/Cranes |

|---|---|---|

| Cost Savings | 30-80% less | Higher, often significant |

| Setup Time | Fast, minimal disruption | Long, disruptive, requires extensive planning |

| Personnel | Fewer, highly trained specialists | More personnel, varying skill levels |

| Flexibility | High, adaptable to complex geometries | Limited, rigid structures |

| Environmental | Lower footprint, less material waste | Higher material usage, potential ground disturbance |

| Safety | Excellent, stringent safety protocols | Good, but higher exposure to traditional risks |

Ensuring Safety and Regulatory Compliance

In industrial inspection and analysis, safety is the foundation of all operations. Adhering to regulations protects lives, the environment, and ensures operational reliability.

The Occupational Safety and Health Administration (OSHA) sets key requirements for workplace safety. A primary metric is the Total Recordable Incident Rate (TRIR), which tracks job-site incidents. A low TRIR indicates a company’s strong commitment to safety.

Environmental Protection Agency (EPA) regulations govern industrial processes related to emissions, waste, and water quality. Inspections help ensure compliance, protecting the environment.

Numerous Industry Standards from organizations like ISO, NADCAP, ASTM, ASME, and ANSI provide best practices for inspection and quality management. Adherence to these standards demonstrates expertise and a commitment to quality. The industry is constantly evolving, with new technologies emerging to improve inspection services and safety.

What to Look for in an Industrial Inspection and Analysis Provider

Choosing the right partner for your industrial inspection and analysis needs is a truly critical decision. Here are some key factors we believe you should always consider:

- Certified Experts: Look for providers with highly trained and certified personnel. Certifications from recognized bodies are simply non-negotiable.

- Comprehensive Solutions: A provider that offers a wide spectrum of services – everything from NDT and laboratory analysis to engineering and specialized access solutions – can truly streamline your processes.

- Proven Experience: Experience truly matters. Look for companies with a long track record of success in your specific industry. Our own team brings over 45 years of experience performing inspections and non-destructive testing for various industries, which speaks volumes about our commitment and expertise.

- Strong Safety Record: As we discussed, a low TRIR and a robust, well-established safety program are clear indicators of a responsible and reliable partner.

- National Footprint: For very large organizations or those with assets spread across different locations, a provider with a national presence can offer consistent service quality and rapid response times.

Here are some of the key certifications you should look for in inspectors:

- ASNT NDT Level I, II, III (American Society for Nondestructive Testing)

- API Certifications (American Petroleum Institute, e.g., API 510, 570, 653 for pressure vessels, piping, tanks)

- AWS Certified Welding Inspector (CWI)

- ISO 9712 (International Standard for NDT personnel qualification)

- FAA Airframe & Powerplant (A&P) Mechanic with Inspection Authorization (IA)

- Rope Access Certifications (e.g., IRATA, SPRAT)

- Professional Engineer (PE) License (for engineering services)

Frequently Asked Questions about Industrial Inspection

Here are answers to some common questions about industrial inspection and analysis.

What is the difference between destructive and non-destructive testing?

That’s a fantastic question, and the answer is actually right in the name!

Destructive Testing (DT) involves testing a sample of a material to its breaking point to determine its mechanical properties, such as strength and hardness. The sample is destroyed in the process, but the data gained is invaluable for understanding material limits.

On the other hand, Non-Destructive Testing (NDT) uses techniques like ultrasound or X-rays to inspect a component for hidden flaws without causing any damage. The component remains intact and can be returned to service after the inspection, which is a major advantage for critical, operational equipment.

How does rope access inspection save money?

Rope access is a highly cost-effective method for inspecting difficult-to-reach areas. It can be anywhere from 30% to 80% cheaper than traditional methods like scaffolding or cranes.

The savings come from requiring fewer personnel and having dramatically faster setup and teardown times. This minimizes disruption to facility operations and reduces asset downtime, leading to significant budget savings.

What is TRIR and why is it important?

TRIR stands for Total Recordable Incident Rate. It is a standard safety metric used by OSHA (the Occupational Safety and Health Administration) to track workplace injuries and illnesses that require medical treatment beyond first aid.

A low TRIR is a very strong indicator of a company’s commitment to safety. It shows they have a robust safety culture and operate with a high degree of professionalism. When you choose an industrial inspection and analysis provider with a low TRIR, you are choosing a partner who values safety, minimizing risk for their teams and your operations.

Conclusion: Securing Your Assets with Expert Analysis

Industrial inspection and analysis is the backbone of modern industry’s safety and reliability. This critical field ensures the integrity of everything from the towering wind turbines that power our cities to the intricate aerospace components that keep us connected globally.

The field’s strength lies in its comprehensive approach. Advanced Non-Destructive Testing allows for internal inspection without damage, while precise laboratory analysis provides molecular-level understanding. When failures occur, detailed forensic engineering finds the root cause, and specialized rope access techniques provide safe, cost-effective access to challenging locations.

What strikes me most after decades in the inspection business is how much the principles remain the same, whether you’re examining a massive industrial facility or a residential building envelope. It’s all about preventing problems before they become disasters, protecting investments, and ensuring everyone’s safety.

Choosing the right inspection partner means finding certified experts with comprehensive services and a proven commitment to safety, reflected in metrics like a low TRIR. The technology keeps evolving, from 3D laser scanning to drone inspections, but the core mission of keeping our built environment safe and functional remains constant.

For specialized building envelope needs, this same dedication to thorough inspection applies on a more personal scale. At Stucco Safe, we bring these same forensic principles to residential and commercial properties throughout Southeastern Pennsylvania, New Jersey, and Delaware. Our certified inspectors use advanced testing methods to detect moisture intrusion and structural issues that could threaten your property’s integrity. Just as industrial facilities rely on expert analysis to protect their assets, your home or commercial building deserves the same level of professional attention. Find stucco inspections near me.