Nondestructive inspection jobs: Thrive in 2025

Why Nondestructive Inspection Jobs Are In High Demand

Nondestructive inspection jobs offer stable careers in a growing field where you test materials and structures without damaging them. These roles are essential across industries like aerospace, oil and gas, manufacturing, and infrastructure maintenance.

Quick Overview of NDT Career Opportunities:

- Entry-level positions: $36,000-$60,000 annually (NDT Trainee)

- Certified technicians: $50,000-$109,000 annually (Level II)

- Senior specialists: $60,000-$123,000 annually (Level III)

- Job growth: 6% projected growth through 2032

- Key industries: Aerospace, energy, transportation, manufacturing

- Required education: High school diploma plus specialized training

- Certification levels: Trainee, Level I, Level II, Level III

The field attracts people from diverse backgrounds including welding, metallurgy, and construction. As Carly Cramblit, an NDE Responsible Level III, explains: “An NDT career can be recommended to almost anyone due to its rewarding nature and the ability to earn a good income without a degree.”

Peak hiring seasons occur during spring and fall shutdown months in industries like oil and gas. Many positions offer union benefits, with wages ranging from $20/hour for trainees to $45/hour for Level 2 technicians with multiple certifications.

I’m Gabe Kesslick, and I’ve been working in inspection and forensic analysis since 2001, including extensive experience with nondestructive testing methods for building envelope investigations. My background in nondestructive inspection jobs spans moisture detection, thermal imaging, and structural assessments across residential and commercial properties.

Basic nondestructive inspection jobs terms:

What is an NDT Technician? A Look at the Role and Responsibilities

NDT inspectors and technicians are crucial for ensuring the safety and integrity of materials, parts, and systems without causing damage. Think of it as a doctor using an X-ray instead of surgery. This “nondestructive” approach is vital across many industries.

An NDT professional needs a sharp eye and a knack for solving puzzles. They work on everything from airplane parts and pipelines to large buildings and residential stucco systems. Here’s a look at their common responsibilities:

- Equipment Setup: Technicians carefully set up and calibrate specialized NDT equipment to ensure accurate results.

- Performing Inspections: Using methods like ultrasonic, radiographic, or magnetic particle testing, they search for hidden flaws such as cracks, voids, or weld defects.

- Data Interpretation: They analyze test data—from screen readouts to X-ray images—to identify and interpret indications of flaws.

- Reporting: Detailed reports are created to document findings, test procedures, and recommendations, ensuring compliance with safety and quality standards.

- Safety Compliance: Adhering to strict safety protocols is essential, especially when working with specialized equipment or in hazardous environments.

- Problem-Solving: Technicians help determine the cause of defects and their potential impact, contributing to material and structural solutions.

As the O*NET system describes, NDT experts “test the safety of structures, vehicles, or vessels using x-ray, ultrasound, fiber optic or related equipment.” This involves comparing test results against strict standards, identifying defects, and writing comprehensive reports. Their work is a key part of Industrial Inspection and Analysis in many fields.

Key Industries and Work Environments

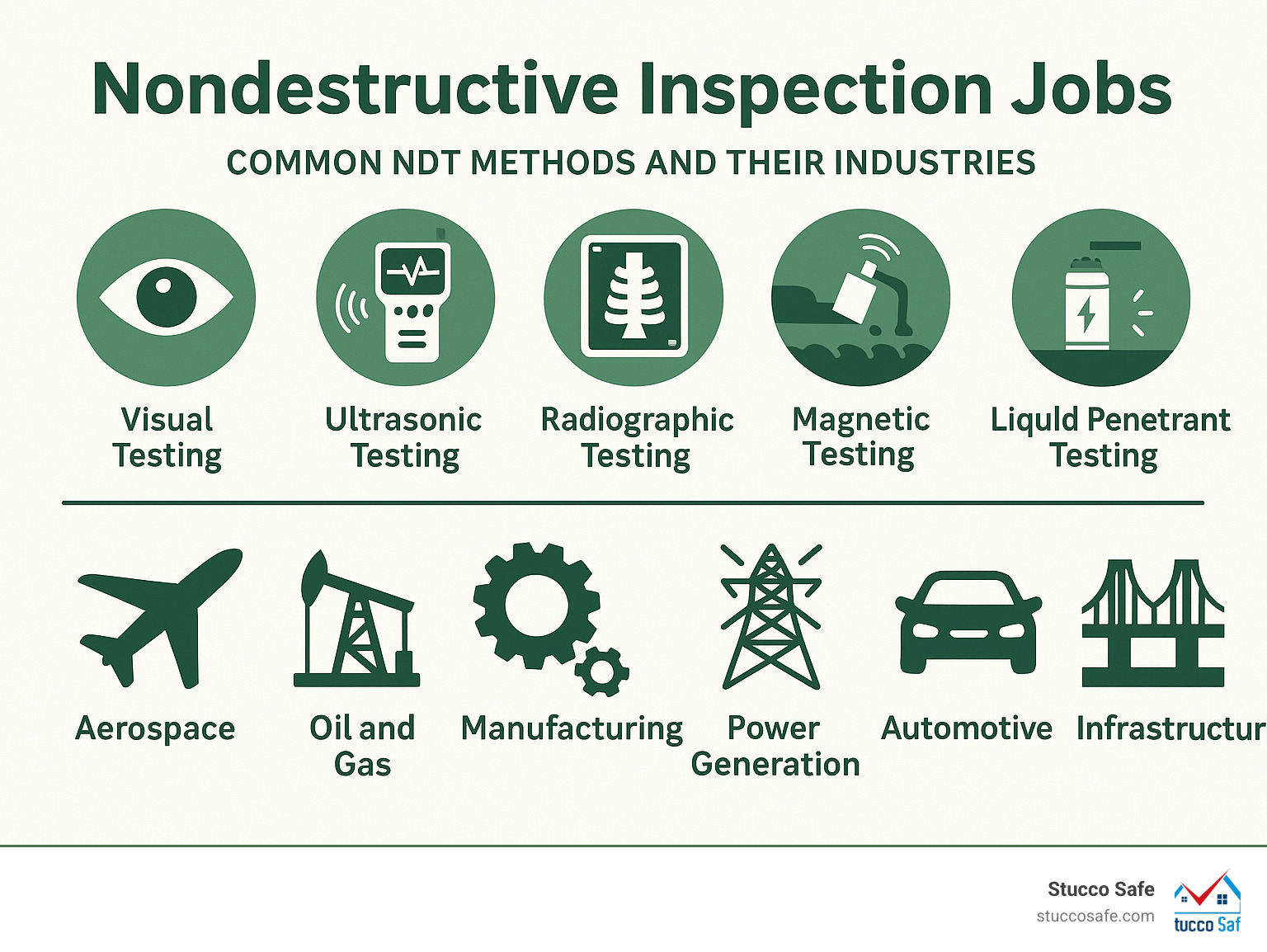

One of the best aspects of an NDT career is its wide application. Nearly every industry that relies on strong, reliable materials needs NDT professionals, meaning nondestructive inspection jobs are always in demand. Key industries include:

- Aerospace: Ensuring the safety of planes, rockets, and their components, from engine blades to aircraft fuselages.

- Oil & Gas: Preventing leaks and failures in pipelines, refineries, and offshore platforms.

- Manufacturing: Checking the quality of products like car parts and heavy machinery during production.

- Power Generation: Ensuring the structural integrity of tanks, pipes, and turbines in nuclear plants, power stations, and wind farms.

- Automotive: Inspecting vehicle parts to ensure they are safe and reliable before reaching the market.

- Infrastructure: Regularly checking bridges, dams, and railways to prevent accidents and ensure public safety.

Here at Stucco Safe, we use nondestructive inspection ideas for buildings, especially to find moisture and structural issues in stucco and stone siding. We use special forensic testing methods to check the health of homes in Southeastern Pennsylvania, New Jersey, and Delaware, making sure they’re safe and last a long time for homeowners and buyers. Our work fits perfectly under the umbrella of Building Envelope Inspection for homes.

Physical Demands of the Job

While highly technical, NDT work is often physically active. An NDT professional’s “office” can range from a clean lab to a rugged industrial site.

- Confined Spaces: Working inside tanks, pipes, or crawl spaces.

- Working at Heights: Inspecting tall structures like bridges or towers, sometimes using rope access.

- Variable Weather: Performing outdoor work in all weather conditions.

- Lifting Equipment: Carrying gear that can weigh up to 50 pounds (about 23 kg).

- Physical Fitness: The job requires standing for long periods, bending, kneeling, and climbing.

- Travel: Many nondestructive inspection jobs require travel to various job sites.

As the British Institute of NDT (BINDT) notes, NDT work can involve “arduous conditions.” It’s a career that attracts adventurous individuals who enjoy a challenge.

Your Pathway to a Career in Nondestructive Inspection

A career in Nondestructive Testing (NDT) is a high-demand, well-paying profession with a clear path for growth. The journey involves a mix of education, hands-on training, and essential certifications that build your expertise step by step.

Educational Foundations

To start in nondestructive inspection jobs, a four-year degree isn’t always necessary, but a solid technical foundation is. A High School Diploma or GED is the typical starting point. From there, many aspiring technicians attend Community Colleges or Technical Schools that offer associate degrees or specialized diplomas in NDT technology. These programs provide a valuable mix of classroom theory and practical, hands-on training.

Two subjects are especially important: Strong Math Skills for calculations and data analysis, and a good understanding of Materials Science. Knowing how materials are made and behave is vital for effective inspection. A background in a related field like welding, metallurgy, or construction can also provide a significant advantage.

Essential Certifications: The Key to Nondestructive Inspection Jobs

Certification is your proof of competence in the NDT world. It demonstrates your knowledge and skill, opening doors to better jobs and career advancement. Certifications are typically structured in levels of increasing expertise.

In the United States, the ASNT Certification (American Society for Nondestructive Testing) is the industry standard. The levels generally include:

- Level I Trainee: Works under direct supervision to learn equipment use and data collection basics.

- Level II Inspector: Sets up equipment, performs inspections, interprets results according to standards, writes reports, and can guide Level I personnel.

- Level III Specialist: An expert who develops testing methods, interprets complex codes, oversees NDT programs, and trains and certifies other personnel.

In Canada, the CGSB (Canadian General Standards Board), working with Natural Resources Canada (NRCan), is the key certifying body. To get certified, you need to complete required training and accumulate practical experience hours, which can sometimes feel like a “chicken and egg” situation. Many technicians start in entry-level roles to gain this crucial on-the-job experience. Getting certified is a critical step to securing nondestructive inspection jobs. You can learn more about how to Get Certified with ASNT.

Career Progression: From Trainee to Expert

The NDT field offers clear paths for advancement. With each certification and added experience, your responsibilities and earning potential grow.

A typical career path looks like this:

- Trainee/Assistant: Learns the basics under close supervision.

- NDT Technician (Level I/II): Performs inspections independently or leads small teams.

- NDT Specialist (Level III): A top expert who develops procedures, oversees programs, and mentors others.

- Supervisor/Manager: Moves into management, overseeing NDT teams, projects, or departments.

Further advancement can lead to roles like NDT Engineer, which combines NDT with engineering principles for design and research, often falling under Inspection Engineering. Other paths include becoming a Quality Manager, Instructor, or an independent Consultant. As Jesse Groom, an Innovative Tech Lead in NDT, points out, real-world field experience is incredibly valuable for developing new technologies. It’s a field where hard work and dedication truly pay off.

Mastering the Methods: Key Disciplines in NDT

The heart of nondestructive inspection jobs lies in the diverse array of methods used to uncover hidden truths about materials without altering them. Each method employs unique physical principles to detect flaws, measure properties, or characterize materials. Understanding these disciplines is fundamental to a successful NDT career.

NDT is used to inspect and evaluate materials, components, or assemblies without destroying their serviceability. This is vital for ensuring product integrity, controlling manufacturing processes, lowering production costs, and maintaining uniform quality.

List of Common NDT Techniques

While there are many NDT methods, some are more widely used across industries due to their versatility and effectiveness. Here are the most frequently employed techniques:

- Visual Testing (VT): The most basic method, involving direct visual examination for surface flaws like cracks or corrosion. It can be improved with tools like borescopes and drones.

- Ultrasonic Testing (UT): Uses high-frequency sound waves to detect internal flaws or measure thickness. It’s widely used for inspecting welds and materials.

- Phased Array UT (PAUT): An advanced UT technique that uses multiple ultrasonic elements for more detailed imaging of flaws.

- Time of Flight Diffraction (TOFD): Another advanced UT method primarily used for accurate flaw sizing in weld inspections.

- Radiographic Testing (RT): Uses X-rays or gamma rays to create an image of a material’s internal structure, revealing flaws like voids or cracks. It is highly regulated due to radiation use.

- Magnetic Particle Testing (MT): For ferromagnetic materials, this method uses magnetic fields and fine particles to reveal surface and near-surface flaws.

- Liquid Penetrant Testing (PT): Detects surface-breaking flaws in non-porous materials by using a liquid dye that seeps into cracks and becomes visible with a developer.

- Eddy Current Testing (ET): Uses electrical currents to find flaws in conductive materials. It is common for inspecting aircraft structures and heat exchanger tubing.

At Stucco Safe, our expertise in Moisture Intrusion Detection uses principles akin to NDT, employing specialized equipment and forensic methods to identify hidden moisture within building envelopes without destructive demolition. This ensures we can assess the integrity of a home and provide crucial information to homeowners and buyers without causing further damage to the property.

Landing Nondestructive Inspection Jobs: Skills, Salaries, and Outlook

The exciting news about nondestructive inspection jobs is that they’re in high demand, pay well, and offer genuine job security. Whether you’re just starting out or looking to advance your career, understanding what employers want and what you can expect to earn makes all the difference.

Top Skills Employers Look For

When hiring for nondestructive inspection jobs, managers look for a combination of technical expertise and essential soft skills.

- Attention to detail: Missing a tiny flaw can have catastrophic consequences, so employers need technicians who can spot and document the smallest irregularities.

- Technical aptitude: A strong interest in how things work is crucial for calibrating equipment and interpreting complex data.

- Integrity: Professionals must report findings honestly, even when the results are unwelcome, to uphold public safety and the law.

- Communication skills: Clear report writing and the ability to explain technical findings to diverse audiences are essential.

- Safety-first mindset: Consistently following safety protocols is non-negotiable due to work with radiation, in confined spaces, and around hazardous materials.

- Computer proficiency: Proficiency with software for data acquisition, analysis, and reporting is increasingly important.

As Quinton LeJeune, a Field Application Engineer, notes, NDT work is rewarding because it requires “critical thinking, problem-solving, and assessing things important to public safety.”

Salary Expectations and Job Outlook

The financial rewards of nondestructive inspection jobs reflect the specialized skills involved. Your earning potential grows significantly with experience and certifications.

- Entry-level wages: Trainees typically earn $36,000 to $60,000 annually.

- Certified technician pay: With Level II certification, salaries jump to a range of $50,000 to $109,000 annually.

- Senior specialist pay: Level III professionals can earn between $60,000 and $123,000 annually, often with supervisory responsibilities.

The U.S. Bureau of Labor Statistics projects 6% job growth for NDT technicians through 2032, which is average for all occupations. This reflects ongoing needs in infrastructure maintenance and manufacturing. Demand is highest in aerospace hubs and oil and gas regions, with peak hiring often occurring during spring and fall maintenance seasons. Union positions often offer higher wages and better benefits.

For current opportunities, Find NDT Jobs on NDT.org is a comprehensive resource for professionals.

What is the Future Outlook for Nondestructive Inspection Jobs?

The future of nondestructive inspection jobs is bright, driven by technological innovations that make the field safer and more precise.

- Drones and Robotics: Unmanned systems are increasingly used for inspections in hazardous or hard-to-reach areas, improving safety and efficiency.

- Advanced Imaging: Technologies like digital radiography and improved ultrasonic imaging provide clearer, more detailed results with greater safety.

- AI-Powered Analysis: Machine learning helps analyze complex data, augmenting human expertise to improve flaw detection accuracy.

- Virtual Reality (VR) Training: VR provides safe, simulated environments for technicians to practice complex inspection scenarios without real-world risk.

- Digital Reporting: Cloud-based platforms streamline data management and reporting, enabling real-time collaboration and better data accessibility.

These advances create opportunities for technicians who accept continuous learning and adapt to new technologies, combining traditional expertise with modern digital skills.

Frequently Asked Questions about NDT Careers

It’s natural to have questions when you’re looking into a new career path, especially one as specialized as NDT! Here are answers to some common questions about entering the field.

How long does it take to get NDT certified?

The time to get NDT certified varies depending on the inspection method, certification level (I, II, or III), and your prior experience. Certification requires a combination of formal classroom training, documented on-the-job experience hours, and passing written and practical exams.

For example, becoming a Level II in a complex method like Ultrasonic Testing (UT) may require hundreds of training and experience hours. Simpler methods like Magnetic Particle Testing (MT) require less time. Gaining the necessary on-the-job experience is often the most time-consuming part of the process, which is why many technicians start in entry-level trainee roles to build their hours.

What industries have the highest demand for NDT technicians?

NDT skills are in high demand across any industry where safety and structural integrity are critical. The highest demand for nondestructive inspection jobs is found in:

- Aerospace: For constant inspection of aircraft to ensure flight safety.

- Oil and Gas: For pipelines, refineries, and drilling operations.

- Manufacturing: To ensure the quality of products from car parts to heavy machinery.

- Power Generation: For nuclear plants, power stations, and wind farms.

- National Defense: For rigorous testing of military equipment.

- Infrastructure Maintenance: For ongoing assessment of bridges, railways, and dams.

While these major industries drive demand, NDT principles are widely applicable. At Stucco Safe, we apply them to building envelope inspections, helping homeowners identify hidden issues without damaging their property.

Is NDT a physically demanding job?

Yes, NDT can be physically demanding, especially for field technicians. The level of physical activity depends on the specific role and work environment.

While lab-based roles are less intensive, field work often involves working outdoors in all weather, in confined spaces, or at heights. Technicians may need to lift equipment weighing up to 50 pounds and must be physically fit for standing, bending, and climbing. Safety is always the top priority, with strict protocols and protective equipment used to minimize risks. For those who enjoy a hands-on, dynamic work environment, it can be an incredibly rewarding career.

Conclusion

Nondestructive inspection jobs represent more than just a career choice – they’re a pathway to becoming a guardian of public safety and structural integrity. Whether you’re drawn to the technical challenges, the variety of work environments, or the satisfaction of preventing disasters before they happen, this field offers something truly special.

The beauty of NDT lies in its diversity. One day you might be inspecting aircraft components in a pristine hangar, and the next you could be testing pipeline welds in a remote location. It’s a field that rewards continuous learning, where each new certification opens doors to better opportunities and higher earnings.

The path forward is clear: start with a solid educational foundation, pursue your certifications methodically, and accept the physical and mental challenges that come with the territory. The investment in training and experience pays dividends throughout your career, with nondestructive inspection jobs offering stability even during economic uncertainty.

Technology continues to reshape how we work, bringing exciting innovations like drone inspections, AI-powered analysis, and advanced imaging techniques. This means NDT professionals who stay current with these developments will find themselves at the forefront of their field, with even greater opportunities ahead.

At Stucco Safe, we apply these same nondestructive principles to protect homeowners in Southeastern Pennsylvania, New Jersey, and Delaware. Our forensic testing methods allow us to detect moisture and structural issues in stucco systems without causing damage to your property – just like industrial NDT technicians protect critical infrastructure. Our stucco inspections typically range from $495 to $1595 or more for very large homes, providing peace of mind through thorough, non-invasive analysis.

If you’re ready to start on a career where your work directly contributes to safety and quality across countless industries, nondestructive inspection jobs awaits. And if you’re a homeowner concerned about the integrity of your stucco, we’re here to help you find what lies beneath the surface. Schedule Your Stucco Inspection today and experience the value of nondestructive testing firsthand.