Pipeline Inspection Services: Headache-Free 2025

Safeguarding Our Lifelines: An Introduction to Pipeline Inspection Services

Pipeline inspection services are essential for keeping the vast networks of pipelines that move oil, gas, water, and other vital resources safe. These are regular check-ups for our hidden lifelines, with several critical goals:

- Ensure Safety: Prevent leaks, ruptures, and other failures that can harm people and the environment.

- Maintain Integrity: Check the pipeline’s structure to make sure it’s strong and working as it should.

- Optimize Efficiency: Keep materials flowing smoothly, preventing blockages and slowdowns.

- Comply with Regulations: Meet strict government rules designed to protect everyone.

- Extend Lifespan: Help pipelines last longer, avoiding costly full replacements.

- Reduce Costs: Find small problems early before they become huge, expensive disasters.

Since pipelines are often buried, small issues like corrosion or cracks can become major problems if unchecked. Regular inspections catch these issues early, helping companies avoid accidents, environmental damage, and costly emergency repairs. This proactive approach ensures safe and efficient operation.

As the founder of Stucco Safe, I apply a forensic approach to uncovering hidden issues, similar to the detailed work in pipeline inspection services. My background in building envelope forensics and moisture detection offers a unique perspective on why thorough, certified inspections are vital for critical infrastructure.

Must-know pipeline inspection services terms:

The Core Mission: Why Pipeline Inspection is Non-Negotiable

Pipeline inspection services are far more than a technical chore; they are essential for protecting our communities, environment, and economy. The modern world depends on the uninterrupted flow of oil, natural gas, and clean water through these vast, often hidden networks. Keeping this infrastructure healthy and functional is non-negotiable.

The primary purpose of pipeline inspection services is to maintain a pipeline’s integrity throughout its entire lifecycle. The goal is to identify and fix common problems like corrosion, cracks, or physical damage long before they can escalate into a major leak or catastrophic break.

For the oil and gas industry, inspections prevent costly leaks that cause environmental damage, production shutdowns, and heavy fines. For water utilities, sound pipelines ensure the delivery of safe drinking water and prevent wasteful leaks that drain resources. This proactive maintenance extends pipeline lifespan, avoiding the enormous cost of full replacements and protecting the public.

The American Water Works Association constantly highlights the importance of maintaining our water infrastructure. Strong pipeline inspection services are a huge part of this, ensuring these critical systems can serve us safely and reliably for years to come.

Benefits of Specialized Pipeline Inspection Services

Choosing specialized pipeline inspection services offers significant advantages for asset management, cost reduction, and operational efficiency. Good information is the key to smart decisions, which these services provide.

One of the biggest perks is enabling targeted repairs instead of expensive, full-scale replacements. By pinpointing the exact location and severity of defects, resources can be allocated precisely where needed. This approach saves money, reduces shutdown times, and avoids unnecessary disruptions. Knowing the exact problem spots helps companies budget their repair efforts smartly, avoiding the cost of replacing entire sections.

These services are also vital for inspecting “unpiggable” pipelines, which are not designed for standard tools. Expert teams have developed innovative solutions for these complex scenarios, providing accurate assessments and reducing the need for unnecessary repairs. As a core part of any asset integrity management plan, these inspections provide the data needed to extend pipeline life, minimize safety risks, and ensure compliance. Just as we emphasize Understanding Stucco Testing: Ensuring Your Home’s Integrity, specialized pipeline inspection services are vital for the long-term health of critical infrastructure.

Ensuring Safety and Regulatory Compliance

Safety and regulatory compliance are the highest priorities in pipeline inspection services. Adhering to strict regulations from bodies like the Pipeline and Hazardous Materials Safety Administration (PHMSA) and the EPA is a legal and ethical mandate to prevent accidents and protect the environment.

Inspections must verify that pipelines meet or exceed these industry standards. This process requires detailed record-keeping for audits to demonstrate compliance and reduce liability, which in turn demands certified and highly skilled inspectors to find hidden issues.

Service providers are typically experts in specific regulations, such as PHMSA requirements for gas pipelines or OSHA safety standards, ensuring their teams hold the proper certifications. This expertise guarantees all work meets safety and environmental rules. By thoroughly inspecting pipelines and providing clear reports, they help operators maintain compliance, reducing the risk of fines, legal trouble, and accidents. Industry groups like the National Association of Sewer Service Companies (NASSCO) also play a role by setting standards that keep water and wastewater networks safe and functional.

A Look Inside: Common Pipeline Inspection Technologies

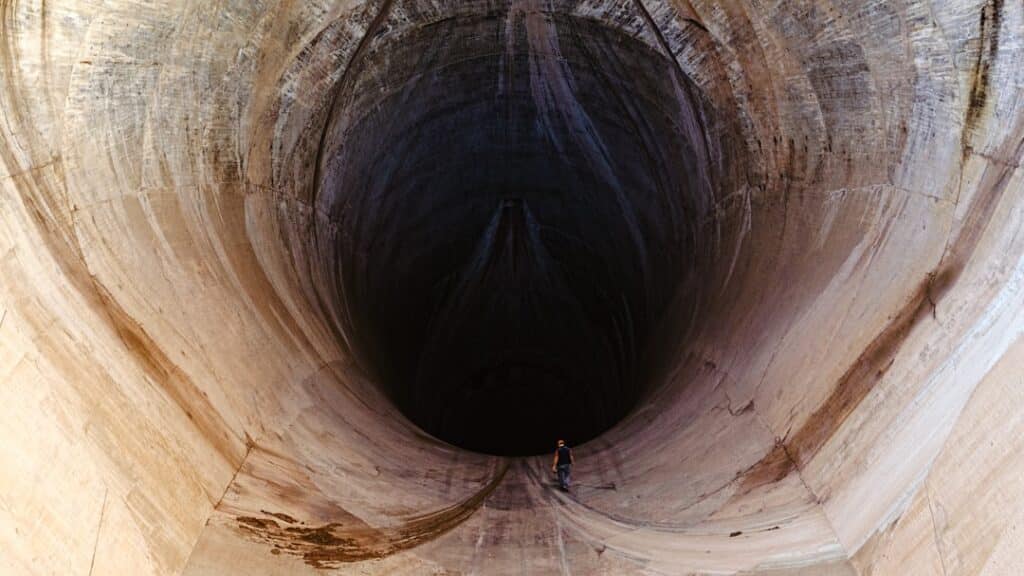

Inspecting pipelines involves looking for subtle clues about their health, much like a doctor diagnosing a patient. The goal is to get a clear picture of the pipeline’s condition without causing damage, using various pipeline inspection technologies.

The primary methods fall into two categories: In-Line Inspection (ILI) and Non-Destructive Testing (NDT). ILI involves sending tools called “Smart Pigs” through the pipeline. NDT is a broader term for techniques used inside or outside to find flaws without altering the pipe. A key distinction is between piggable pipelines, designed for ILI tools to pass through easily, and unpiggable pipelines, which have features like sharp bends or size variations that block standard tools. Fortunately, experts have developed unique solutions for even the most challenging non-piggable lines. These advanced tools gather vast amounts of data, forming the basis for informed maintenance and repair decisions.

Internal Inspection Methods

For internal inspections, Smart Pigs are the workhorses, loaded with sensors to find various problems.

One popular technology is Magnetic Flux Leakage (MFL). Ideal for metal pipelines, MFL tools create a magnetic field around the pipe wall. Metal loss from corrosion pitting or thin spots causes the field to “leak,” which sensors detect to locate and size the defect. It’s highly effective for finding both internal and external corrosion.

Another powerful tool is Ultrasonic Testing (UT). UT tools use sound waves to measure pipe wall thickness and can find tiny cracks or other material flaws. These systems collect detailed data, providing precise measurements of defects.

Caliper Tools use mechanical arms to measure the pipeline’s internal diameter. They are key for finding dents, deformations, or changes in shape that could impede flow or indicate structural issues.

These internal methods are vital for detecting a range of issues, including corrosion, cracks, mechanical damage, manufacturing defects, weld anomalies, and pipe movement. The forensic detail of these inspections mirrors our approach at Stucco Safe, where we use Invasive Stucco Testing to uncover hidden structural issues.

External and Remote Inspection Methods

While internal inspections provide an inside view, external and remote methods offer a different perspective, often without interrupting pipeline operation.

Robotic crawlers, equipped with cameras for CCTV video inspection, lights, and other sensors, are ideal for smaller or hard-to-reach pipes. They can steer through the pipe for a visual check, making them useful for detailed inspections of specific sections where traditional pigs cannot go.

Acoustic sensors are designed to “hear” the tiny sounds of leaks. Whether used in a Smart Pig or placed externally, this technology can pinpoint the exact location of even small leaks, helping to prevent product loss and environmental harm.

Advanced systems also use laser mapping to create detailed 3D maps of the pipeline’s exterior or interior. This can be used to check for external corrosion, track pipe movement, or supplement data from ILI tools, providing a highly accurate picture of the pipe’s condition.

These external and remote methods are valuable for continuous monitoring, leak detection, and inspecting problem areas with minimal disruption, much like our Non-Invasive Inspection approach for property assessments.

From Data to Decisions: The Brains Behind Modern Inspections

In pipeline inspection services, gathering data is only the first step. The real value comes from changing that raw data into clear, actionable insights. This process of turning data into smart decisions is what keeps pipelines strong and healthy.

Today’s inspection tools collect terabytes of information. Without intelligent analysis, this data would be overwhelming. This is where advanced analytics, artificial intelligence (AI), and machine learning (ML) are essential. AI sifts through massive datasets to find hidden patterns and predict potential problems before they become critical. For example, AI can be trained to identify specific defect types, making inspections faster and more accurate. This enables predictive maintenance, allowing operators to schedule repairs proactively rather than reacting to emergencies.

Another key innovation is the “digital twin”—a virtual replica of a physical pipeline. Updated in real-time with inspection data and performance metrics, the digital twin gives engineers a complete view of the pipeline’s health. They can run simulations to test how different decisions might impact the pipeline’s future.

Tools like Intertek’s PipeAware™ also play a vital role by creating systems that provide easy access to a pipeline’s complete lifecycle data, from manufacturing to operation. This ensures all information contributes to a full understanding of the pipeline’s condition.

The goal is to move beyond simply finding defects to understanding their cause and future implications. This data-driven approach is crucial for ensuring long-term safety and reliability, much like the detailed analysis we perform in Forensic Building Inspections to diagnose property issues.

Overcoming Problems with Innovative Pipeline Inspection Services

The pipeline industry faces several significant challenges. Many vital pipelines are part of an aging infrastructure, where their remaining lifespan and structural integrity are uncertain. This can hide issues not visible from the surface, making advanced pipeline inspection services essential for forensic-level analysis.

Beyond age, pipelines often operate in harsh environments, from extreme temperatures to corrosive soils and remote offshore locations, which makes inspections difficult and risky. Access limitations are another problem, particularly with “unpiggable” pipelines not designed for standard tools. This requires innovative solutions to ensure even the most difficult assets are inspected. Finally, modern inspections generate a data overload, and turning this raw data into actionable insights requires sophisticated management and analytics.

Conquering these challenges requires a holistic approach to threat management, understanding not just a single defect but its context and impact on the entire system. This comprehensive view ensures safe and reliable operation, as seen in efforts like those in San Diego to maintain water pipelines with high-tech methods. You can learn more about these advancements here: High-tech ways San Diego’s water transmission pipelines are maintained.

Emerging Trends in Pipeline Inspection Technology

The field of pipeline inspection services is constantly evolving, driven by the need for greater accuracy and efficiency in inspecting complex infrastructure. Several emerging trends are set to revolutionize how pipelines are monitored.

For hard-to-reach places, advanced robotics are stepping up. Intelligent robotic crawlers can steer tricky pipe bends and carry specialized sensors into areas once deemed impossible to inspect. For external assessments, drone inspections are soaring in popularity. Equipped with high-resolution cameras, thermal imaging, and gas leak detectors, drones offer a fast, safe way to cover vast distances.

We’re also seeing the rise of miniaturized sensors. These tiny sensors allow for versatile inspection tools, including free-swimming devices that can be deployed in active pipelines with minimal disruption to gather precise data. AI-powered defect recognition is another game-changer, as machine learning analyzes inspection data in real-time, flagging potential issues and speeding up the review process. Finally, improved data visualization is changing how we understand complex information, with software creating intuitive 3D models that help engineers make informed decisions.

These innovations represent a shift towards more proactive and predictive maintenance, allowing operators to address potential issues before they become critical. This drive for innovation mirrors our commitment to comprehensive Building Envelope Inspection Services, as we constantly seek better ways to protect structures from unseen threats.

The Mark of a Professional: Qualifications and Certifications

While the technology in pipeline inspection services is impressive, it’s only as effective as the skilled professionals operating it. The qualifications and certifications of inspectors are therefore critical for safeguarding our vital pipelines. A professional inspection relies on certified inspectors with deep technical expertise, a commitment to continuous learning, and a thorough understanding of industry standards.

This specialized field requires a blend of knowledge, practical skills, and experience. An inspection team often includes a diverse group of experts, from project supervisors to specialists in coatings and welding, to cover all aspects of pipeline health. Competence is proven through rigorous training programs, hands-on field experience, and challenging exams. Because technology and regulations constantly evolve, continuous learning is essential for inspectors to stay current with the latest methods and provide reliable assessments. This dedication to expertise marks a true professional, much like our commitment to qualified inspectors at Stucco Safe, which leads clients to ask Why Hire a Separate Stucco Inspector?.

Key Qualifications for Pipeline Inspection Personnel

To ensure the highest standards in pipeline inspection services, personnel hold specific certifications demonstrating proven expertise in non-destructive testing and pipeline operations.

A foundational certification for many professionals comes from the American Society for Nondestructive Testing (ASNT). This group certifies inspectors in methods like Ultrasonic Testing (UT) and Magnetic Particle Testing (MT), confirming their ability to perform tests and interpret results. You can learn more at the American Society for Nondestructive Testing (ASNT).

Certifications from NACE International are highly respected for professionals dealing with corrosion, a primary cause of pipeline failure. NACE-certified inspectors are crucial for assessing and mitigating corrosion risks.

The API 1169 certification from the American Petroleum Institute (API) is for pipeline construction inspectors, ensuring new projects meet industry and government standards.

An AWS Certified Welding Inspector (CWI), from the American Welding Society, ensures that all welding work meets strict quality and safety standards.

Finally, for pipelines under U.S. Department of Transportation (DOT) regulations, personnel must have DOT Operator Qualification (OQ). This program ensures individuals are trained and tested for safety-critical tasks.

These certifications, combined with extensive field experience, are the backbone of a competent pipeline inspection team, providing confidence that they have the skills to keep our infrastructure safe.

Conclusion

Pipeline inspection services are far more than routine maintenance; they are the guardians of our modern way of life, protecting the invisible networks that power our economy and deliver vital resources. These inspections are critical for ensuring safety, maintaining structural integrity, optimizing efficiency, and extending the lifespan of massive infrastructure investments, all while ensuring regulatory compliance.

The technology is remarkable, from internal Smart Pigs using MFL and UT to external robotics and sensors. This is improved by AI and machine learning, which turn vast amounts of data into actionable insights, allowing for predictive maintenance.

While challenges like aging infrastructure and harsh environments are significant, the industry innovates with advanced robotics, drones, and AI-powered defect recognition. Behind this technology are the highly qualified and certified personnel whose expertise ensures every inspection meets the highest professional standards.

Just as industrial pipelines require forensic analysis to ensure public safety, the critical systems of your property, like the building envelope, demand specialized, certified inspection to prevent costly damage. At Stucco Safe, we bring this same forensic and analytical approach to protecting homes and properties.

We understand that whether dealing with industrial infrastructure or your home’s stucco walls, the principles are the same: thorough investigation, certified expertise, and proactive problem-solving. Our professional stucco inspection and testing services serve home buyers and property owners across Southeastern Pennsylvania, New Jersey, and Delaware.

Stucco Inspections vary in cost from $495 to $1595 or more for very large homes – a small investment for the peace of mind that comes from protecting your property with the same level of detail seen in industrial inspections.

If you’re ready to safeguard your property with certified, forensic-level inspection services, we’re here to help. You can Find certified stucco inspections near me and ensure your home’s integrity is never left to chance.