Stucco Anchor Bolts: Top 5 Safe & Secure

Why Your Stucco Wall Needs Special Anchors

Stucco anchor bolts and anchors are specialized fasteners designed to securely mount items to stucco surfaces without causing damage. Here’s what you need to know:

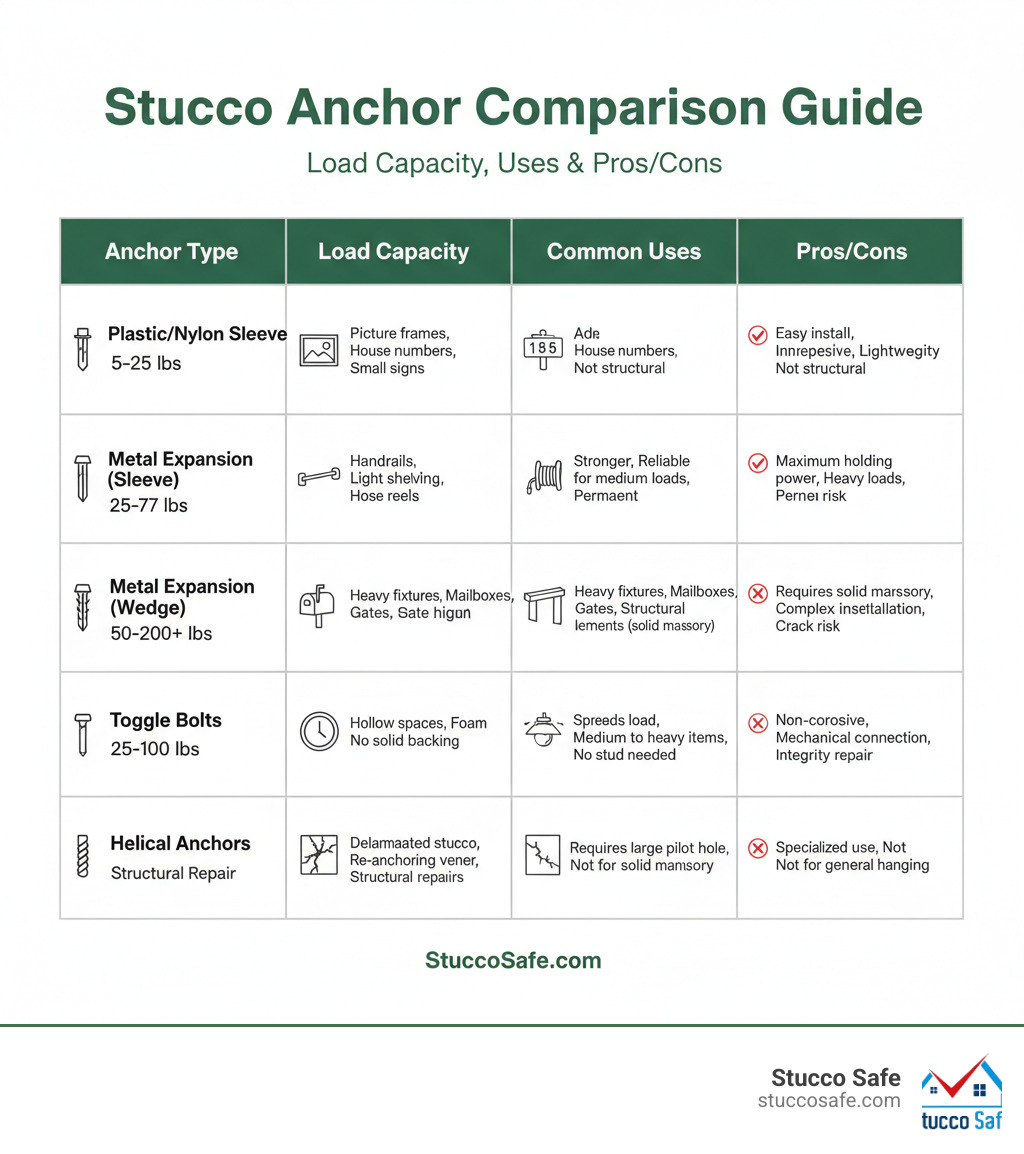

| Anchor Type | Best For | Weight Capacity | Key Feature |

|---|---|---|---|

| Plastic/Nylon Sleeve | Picture frames, house numbers | 5-25 lbs | Easy installation, low cost |

| Metal Expansion | Handrails, hose reels | 25-75 lbs | Reliable mid-weight hold |

| Wedge Anchors | Heavy fixtures, mailboxes | 50-200+ lbs | Maximum holding power |

| Concrete Screws | Versatile use over masonry | 20-80 lbs | Self-threading design |

| Toggle Bolts | Hollow spaces, foam backing | 25-100 lbs | Grips behind hollow areas |

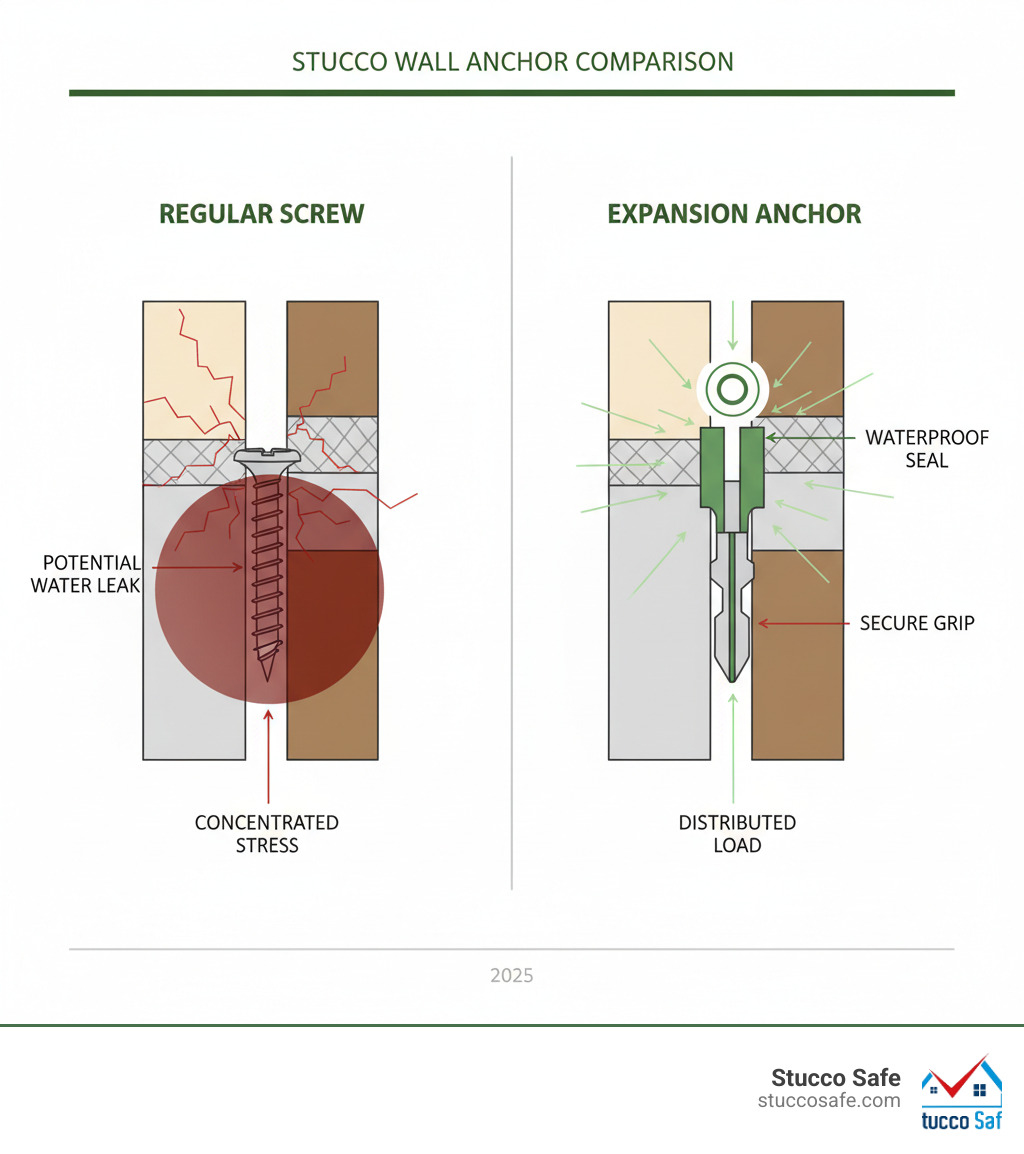

Stucco is a hard, brittle material that cracks easily under concentrated stress. Ordinary screws can’t get a secure grip, often loosening and creating cracks that allow moisture to seep behind your walls.

Stucco anchors solve this by expanding behind the finish to distribute the load, preventing cracks and providing a secure hold. However, every hole you drill is a potential entry point for water.

Moisture intrusion is a leading cause of serious stucco problems, leading to hidden, expensive damage to sheathing and framing. Proper installation is critical to protect your home’s structural integrity.

I’m Gabe Kesslick of Stucco Safe. With over two decades of forensic testing, I’ve seen countless cases where improper anchoring led to hidden moisture damage. Correctly selecting and installing stucco anchor bolts is a critical,, aspect of stucco maintenance.

A Guide to Different Types of Stucco Anchor Bolts

Stucco is a durable but brittle cement coating. Regular screws can crack the surface or loosen over time, so using the right stucco anchor bolts is essential. Your choice depends on the item’s weight, the substrate behind the stucco, and environmental exposure.

Plastic and Nylon Sleeve Anchors

Ideal for lightweight items like house numbers and picture frames, these anchors are simple to use. You drill a pilot hole, insert the sleeve, and as the screw is driven, the sleeve expands. They typically support 5 to 25 pounds and are inexpensive and easy to install. Always match the anchor size to your item’s weight. For more guidance, see our guide on the Best Anchors for Stucco.

Metal Expansion Anchors (Sleeve & Wedge)

For heavier items like handrails, hose reels, and mailboxes, metal expansion anchors are necessary.

Sleeve anchors expand as you tighten the bolt, creating a firm hold for medium-weight fixtures (25 to 75 pounds).

Wedge anchors offer maximum strength for the heaviest loads (50 to 200+ pounds) by expanding with immense force against a solid masonry substrate.

Both provide excellent durability. For more technical details, see these mechanical anchoring products.

Concrete Screws

Concrete screws are versatile fasteners for stucco over concrete or block. These self-threading screws cut their own threads into masonry for a tight grip. Common types include blue Tapcon screws and more neutral tan-colored screws. They typically support 20 to 80 pounds and require a pilot hole. Their self-threading design provides excellent holding power in solid substrates. Learn more in our guide on how to Anchor Screw Into Stucco.

Specialized Anchors for Unique Situations

For unique situations, specialized anchors are needed. Toggle bolts are perfect for hollow areas or walls with foam insulation. Their wings spring open behind the surface, distributing weight and supporting 25 to 100 pounds.

Helical anchors are for structural repair, not hanging items. They re-attach delaminated stucco to the substrate, preserving the wall system’s integrity. Our Stucco Anchor Types guide covers these and other specialized solutions.

How to Choose the Right Anchor for Your Project

Choosing the right stucco anchor bolts protects your home from costly damage. Based on my two decades of inspecting stucco homes, I know that moisture intrusion from improper anchoring is a major risk. Follow these three critical factors to make the right choice.

Factor 1: Load Weight and Item Size

The item’s weight is your first consideration. Always weigh the item before selecting an anchor. For anything over 100 pounds, use multiple anchor points to distribute the load. The load capacities below assume proper installation.

| Anchor Type | Typical Load Capacity (lbs) | Common Uses | Pros | Cons |

|---|---|---|---|---|

| Plastic/Nylon Sleeve | 5-25 | Picture frames, house numbers, small signs | Easy to install, inexpensive, suitable for lightweight items. | Limited weight capacity, not for structural applications. |

| Metal Expansion (Sleeve) | 25-75 | Handrails, light shelving, hose reels | Stronger than plastic, reliable for medium loads, good for permanent fixtures. | Requires precise drilling, can over-stress stucco if overtightened. |

| Metal Expansion (Wedge) | 50-200+ | Heavy fixtures, mailboxes, gates, structural elements (into solid masonry) | Maximum holding power, ideal for very heavy loads, highly durable. | Requires solid masonry behind stucco, more complex installation, can crack stucco if not careful. |

| Concrete Screws | 20-80 | Electrical boxes, conduit, light fixtures (into block/concrete) | Self-threading, versatile for masonry, available in various lengths. | Requires a pilot hole, blue color of some brands can be visible. |

| Toggle Bolts | 25-100 | Heavy mirrors, shelves (over hollow spaces/foam) | Excellent for hollow walls or foam-backed stucco, distributes load widely. | Requires a larger drill hole, can be tricky to install, not for solid masonry. |

| Helical Anchors | Varies (repair specific) | Re-anchoring delaminated stucco | Specifically designed for stucco repair, non-corrosive, discrete. | Not for hanging items, specialized application. |

Factor 2: Substrate Behind the Stucco

The substrate behind your stucco is crucial, as it provides the real holding power. Common substrates include:

- Solid Masonry (Concrete/Brick): This provides the strongest foundation. Use metal expansion anchors (especially wedge anchors) or concrete screws for maximum holding power.

- Wood Sheathing: Common in homes. For heavy items, locate a wall stud and use a long screw (e.g., 2½ to 3 inches) to anchor through the stucco and sheathing directly into the stud.

- Hollow Concrete Block (CMU): The voids require anchors designed for hollow spaces. Toggle bolts or specific sleeve anchors are effective choices.

- Foam Insulation: If you drill into foam, use toggle bolts. They expand behind the foam layer to create a secure hold.

To determine screw length, measure your stucco’s thickness. A typical three-coat system is about ⅞-inch thick, but foam insulation will require longer screws to reach solid backing.

Factor 3: Environmental Exposure

The anchor’s location determines its required material.

- Interior: Standard steel or zinc-plated anchors are sufficient.

- Exterior: The elements require corrosion-resistant fasteners. Stainless steel anchors are the best choice to prevent failure and ugly rust stains. Galvanized or coated screws are a good alternative for less critical applications, but for anything heavy or structural, invest in stainless steel. It prevents costly repairs and difficult-to-remove rust stains.

How to Install Stucco Anchors: A Step-by-Step Guide

Correctly installing stucco anchor bolts is crucial for preventing hidden moisture damage. An improperly sealed hole can allow water to destroy your home’s framing. Following the right technique ensures a secure, long-lasting installation that protects your home.

Essential Tools and Safety Gear

Gather your tools before starting. You will need a hammer drill, carbide-tipped masonry bits matching your anchor size, a caulk gun with exterior-grade silicone caulk, a measuring tape, a level, and a marker. For safety, wear safety glasses and a dust mask. You’ll also need a screwdriver or screw gun.

Step 1: Mark and Drill the Pilot Hole

Carefully measure and mark your anchor’s location. Place painter’s tape over the mark to prevent the drill bit from slipping and to minimize chipping. Use a carbide-tipped masonry bit that exactly matches your anchor’s diameter. Set your drill to the hammer setting and drill a perpendicular hole to the required depth, applying steady pressure. Once drilled, thoroughly clean all dust and debris from the hole with a vacuum or brush for maximum anchor contact.

Step 2: Seal the Penetration

This step is critical and must not be skipped for any exterior stucco anchor bolts installation. To prevent water damage, you must seal the penetration. Fill the cleaned pilot hole with a generous amount of exterior-grade silicone caulk. As you insert the anchor, excess caulk should squeeze out, creating a complete waterproof barrier. Skipping this step can lead to rotted sheathing and framing, resulting in costly repairs. Proper sealing is essential protection for your home. Learn more in our guide on How to Install Anchors in Stucco.

Step 3: Insert the Anchor and Fasten

Gently tap the anchor into the caulk-filled hole until it is flush with the stucco surface. Excess caulk should squeeze out, confirming a good seal. Position your item over the anchor, then drive the screw or bolt into the anchor. Tighten until it feels snug and the item is secure, but do not over-tighten. Over-tightening can strip the anchor, damage the stucco, and compromise the waterproof seal. A firm hold is sufficient. Following these steps protects your home from moisture intrusion and maintains your stucco system’s integrity.

Risks, Maintenance, and Removal

Even properly installed stucco anchor bolts require maintenance. Understanding the risks, performing checks, and knowing how to repair holes will prevent costly surprises.

Understanding the Risks of Improperly Installed Stucco Anchor Bolts

Improper anchor installation is a common cause of serious stucco damage. The main risks include:

- Moisture Intrusion: Unsealed holes allow water to enter the wall cavity, causing hidden rot, mold, and structural damage. This is a major concern for homes built between 1993 and 2006.

- Stucco Cracks: Over-tightening an anchor or using the wrong type can create stress cracks, which are new entry points for water.

- Substrate Rot: The ultimate result of moisture intrusion is rotted wood sheathing and framing, which can be an expensive nightmare to repair.

For a full overview of risks and proper techniques, see our Stucco Anchoring Ultimate Guide.

Maintenance and Replacement

Perform a periodic inspection of exterior anchors twice a year.

- Check for looseness: Gently tug on mounted items. If there’s any play, a careful quarter-turn tightening may be needed.

- Check for corrosion: Look for rust or discoloration, which indicates the anchor’s strength is compromised and can stain your stucco.

- Replace when necessary: Replace any anchor that is corroded, remains loose after tightening, or has caused new cracks. Remove the old anchor, patch the hole, and install a new one nearby.

How to Fix a Hole After Removing an Anchor

When removing an anchor, patching the hole correctly is vital.

- Remove the anchor: Back the screw out and gently pull the anchor. For toggle bolts, you may need to push the toggle through the wall first.

- Clean the hole: Brush out all loose debris and dust.

- Fill the hole: Use an exterior-grade stucco patch compound, packing it in completely.

- Match the texture: While the patch is wet, use a trowel or sponge to mimic the surrounding stucco texture.

- Cure, prime, and paint: Allow the patch to cure fully, then apply an exterior primer and paint to match.

If you have multiple failed anchors or other concerns, a professional inspection from Stucco Safe can identify hidden issues. Our inspections range from $495 to $1,595.

Frequently Asked Questions about Stucco Anchors

Homeowners often have questions about hanging items on stucco. Here are answers to the most common questions we receive about stucco anchor bolts.

How much weight can a stucco wall hold with anchors?

The holding capacity of a stucco wall depends on three factors:

- Anchor Type: A plastic anchor holds 5-25 lbs, while a heavy-duty wedge anchor can support 200+ lbs.

- Substrate: The material behind the stucco is critical. An anchor in solid concrete is far stronger than one in hollow block.

- Installation Quality: An improperly installed anchor will fail, regardless of its rating.

For heavy items (over 100 lbs), always use multiple anchor points to distribute the load and reduce stress on the wall.

Can you screw directly into stucco without an anchor?

No, this is not recommended. Stucco is too brittle to hold a screw’s threads securely, and the screw will loosen over time. The concentrated stress can also crack the stucco, creating a pathway for moisture to enter the wall and cause rot and mold. Always use a proper anchor. For any exterior penetration, even with a masonry screw, you must drill a pilot hole and seal it with exterior-grade silicone caulk to prevent water damage.

What are the best stucco anchor bolts for heavy items?

For heavy items, you need a robust solution. The best options are:

- Wedge Anchors: These are the gold standard for heavy loads when your stucco is backed by solid masonry like concrete or brick. They provide exceptional strength, supporting 50-200+ pounds.

- Lag Shields: Another excellent choice for solid masonry, these expand as a lag screw is driven into them.

- Securing to Wall Studs: For wood-framed walls, this is the strongest method. Use long lag screws to fasten through the stucco and sheathing directly into the wood stud.

Always use multiple anchor points for very heavy items and seal every exterior penetration with silicone caulk to prevent moisture intrusion. If you’re unsure, a professional consultation can provide peace of mind. Our inspections ($495-$1595) can identify issues before they become costly problems.

Conclusion: Secure Your Fixtures, Protect Your Home

Properly choosing and installing the right stucco anchor bolts is crucial for protecting your home’s value and structural integrity. A poorly installed anchor can lead to a five-figure repair bill.

Every hole is a potential entry point for moisture, which can silently destroy your home’s framing. Sealing every penetration with exterior-grade silicone caulk is the single most important step to prevent this. The risk is even greater for homes built between 1993 and 2006, which are already more vulnerable to stucco failure.

If you have any concerns about your stucco’s condition, a professional evaluation from Stucco Safe can prevent costly mistakes. Our forensic inspections ($495 to $1,595+) identify hidden moisture and structural issues, giving you the confidence to proceed safely.

By selecting the right anchor, using the correct technique, and sealing every hole, you are protecting your investment. Learn more about securing items to your stucco and maintaining your home’s exterior in our Stucco Wall Anchors Complete Guide.