Stucco Anchor Types: 3 Ultimate & Secure

Why Stucco Walls Demand Specialized Fasteners

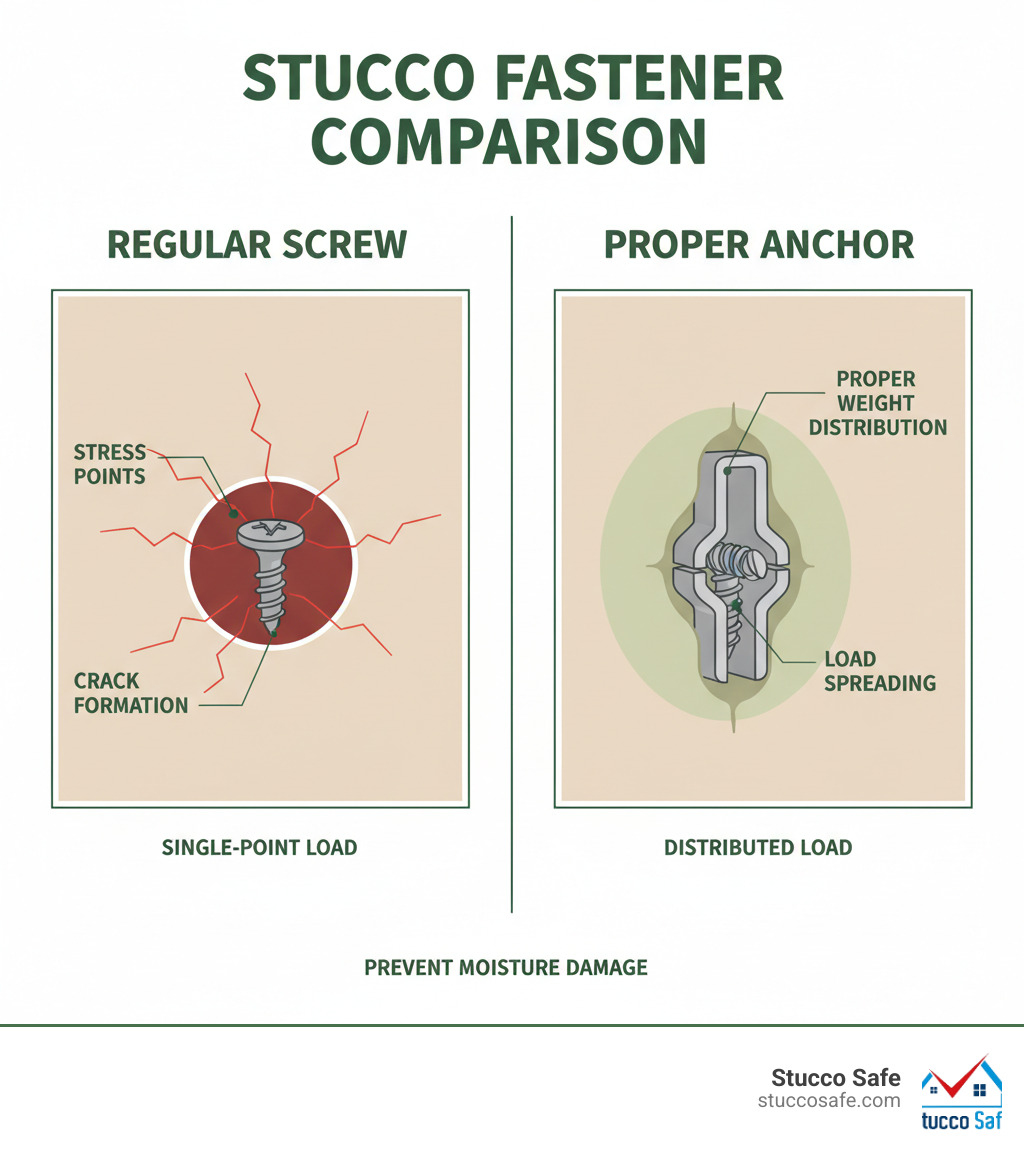

Stucco anchor types are essential fasteners designed specifically for the unique challenges of mounting items to stucco walls. Unlike regular screws that can crack and fail in this brittle cement-based material, specialized anchors distribute weight properly and provide secure, long-lasting attachment points.

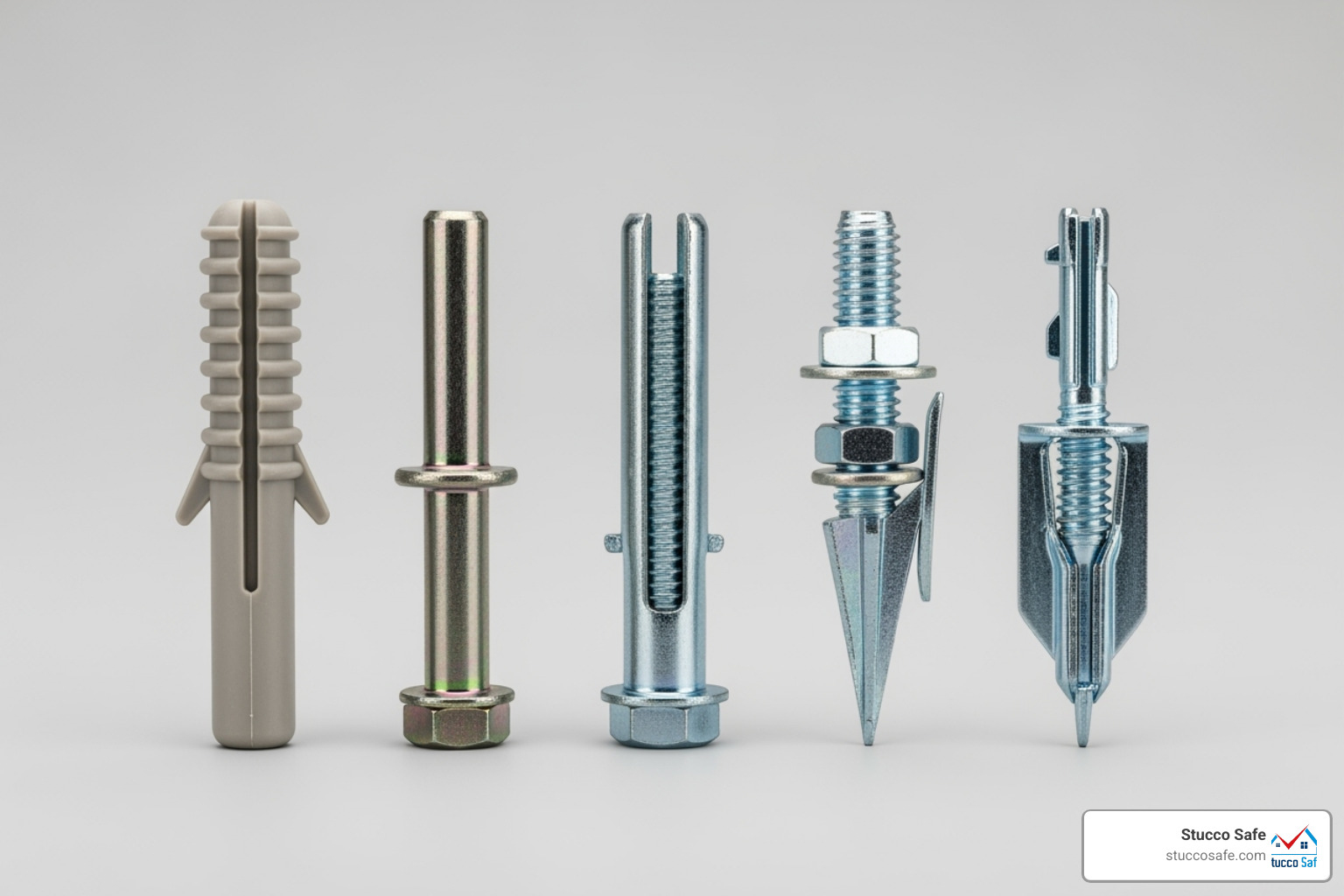

Main Types of Stucco Anchors:

- Light-duty anchors (up to 50 lbs): Ribbed plastic anchors, conical anchors

- Medium-duty anchors (50-200 lbs): Sleeve anchors, masonry screw anchors, concrete screws

- Heavy-duty anchors (200+ lbs): Wedge anchors, toggle bolts, lag shields

Common Materials:

- Carbon steel with zinc plating (corrosion resistant)

- Stainless steel (premium corrosion protection)

- Nylon/plastic (lightweight applications)

Stucco’s cement-based composition makes it both hard and brittle – a combination that causes regular screws to either fail to grip properly or create stress cracks that compromise your wall’s integrity. When water enters these cracks, it can lead to serious moisture problems behind your stucco system.

The key difference between regular screws and stucco anchors lies in how they distribute weight. While a screw creates a single point of stress, anchors expand or spread the load across a wider area of the stucco surface.

I’m Gabe Kesslick, and as an EDI Level 2 Certified Stucco Inspector with over 20 years in leak detection and repair, I’ve seen countless failures caused by improper fastening methods – making proper stucco anchor types selection crucial for wall integrity. Through Stucco Safe, I help homeowners understand these critical building envelope components to prevent costly moisture damage.

Why Your Stucco Wall Needs Special Anchors

Stucco is a cement-based plaster made from Portland cement, sand, and water. This creates a surface that is both incredibly hard and very brittle. Regular screws are not designed for this material; they fail to grip securely and often cause the stucco to crumble or crack under pressure.

This is why specialized stucco anchor types are essential. The key difference is weight distribution. A regular screw concentrates stress at a single point, leading to failure. An anchor is engineered to expand within a pre-drilled hole, spreading the load across a wider area of the stucco. This creates a secure grip without causing stress cracks.

Using the correct Anchor Screw Into Stucco technique is about more than just preventing items from falling. Improper fastening can create cracks that allow for water intrusion. Once moisture gets behind stucco, it can lead to wood rot, mold, and severe structural damage, with repair costs sometimes reaching hundreds of thousands of dollars.

Quality stucco anchors are made from corrosion-resistant materials to ensure longevity. Common options include carbon steel with zinc plating, stainless steel for superior protection in harsh environments, and durable nylon for lighter applications. Choosing the right material prevents the anchor from deteriorating and creating new failure points.

Using the correct stucco anchor types is critical for protecting your home’s building envelope from moisture damage.

The Ultimate Guide to Stucco Anchor Types

When it comes to fastening items to your stucco walls, choosing the right anchor isn’t just about grabbing whatever’s available at the hardware store. Think of stucco anchor types like shoes – you wouldn’t wear flip-flops to climb a mountain, and you wouldn’t use a heavy-duty wedge anchor to hang a small picture frame.

The secret to success lies in matching your anchor to three key factors: the weight of what you’re hanging, the type of material behind your stucco, and the specific demands of your project. We organize stucco anchor types into three main categories based on their load-bearing capacity.

Light-duty anchors handle up to 50 pounds and are perfect for everyday household items like picture frames, towel racks, and small decorations. Medium-duty anchors can support 50 to 200 pounds, making them ideal for shelving, light fixtures, and window boxes. Heavy-duty anchors are the powerhouses, designed for loads over 200 pounds – think awnings, large trellises, and structural attachments.

Here’s a comprehensive breakdown of the most common stucco anchor types and their capabilities:

| Anchor Type | Common Materials | Weight Capacity | Best Uses | Pros | Cons |

|---|---|---|---|---|---|

| Ribbed Plastic/Conical Anchors | Nylon, Plastic | Light-duty (up to 50 lbs) | Pictures, towel racks, lightweight decor, electrical plates | Easy installation, inexpensive, versatile for common items | Limited weight capacity, not for structural support |

| Self-Drilling Anchors | Metal (zinc alloy), Plastic | Light to Medium-duty (up to 50 lbs) | Light to medium objects without pre-drilling | Quick installation, convenient | Less holding power, risk of stucco cracking |

| Masonry Screw Anchors | Carbon steel (often blue-coated) | Medium-duty (50-200 lbs) | Outdoor decorations, shelves, electrical boxes, light fixtures | Very reliable hold, self-tapping, good for textured stucco | Difficult to remove, requires precise hole size |

| Sleeve Anchors | Steel, zinc-plated | Medium-duty (50-200 lbs) | Light fixtures, railings, grab bars, medium shelving | Strong expansion grip, versatile for multiple materials | Requires precise drilling, challenging removal |

| Wedge Anchors | Steel, zinc-plated, stainless steel | Heavy-duty (200+ lbs) | Awnings, large fixtures, trellises, structural support | Highest holding power, extremely durable | Requires solid backing, complex installation |

| Toggle Bolts | Steel bolt, plastic/metal toggle | Medium to Heavy-duty | Heavy items with hollow space behind stucco | Excellent for hollow walls, spreads load widely | Not ideal for solid backing, requires larger holes |

| Lag Shield Anchors | Zinc alloy | Medium to Heavy-duty | Securing lag bolts, vibration-prone applications | Good vibration resistance, works with lag bolts | Requires separate lag bolt, more complex setup |

Common light-duty stucco anchor types

For items up to 50 pounds, light-duty anchors like ribbed plastic anchors and conical anchors are ideal. The ribs on a plastic anchor prevent it from spinning, and it expands as a screw is driven in to create a tight grip. These are perfect for hanging pictures, towel racks, house numbers, and other lightweight decor. Installation is simple: drill a hole, insert the anchor flush with the wall, and drive in the screw.

Versatile medium-duty stucco anchor types

For loads between 50 and 200 pounds, use medium-duty stucco anchor types like sleeve anchors and masonry screw anchors. A sleeve anchor expands within the hole as you tighten its nut, creating a very strong hold. Masonry screw anchors have hardened threads that tap directly into stucco and concrete, providing a solid attachment without a separate plastic anchor. Learn more about them in our guide to Stucco Screw Anchors. These anchors are excellent for shelving, light fixtures, mailboxes, and handrails.

Heavy-duty anchors for serious loads

For loads over 200 pounds or for structural attachments, you need heavy-duty stucco anchor types. These include wedge anchors, toggle bolts, and lag shield anchors. Wedge anchors provide the highest holding power in solid masonry by wedging an expansion clip against the sides of the hole. Toggle bolts are best for hollow walls, as a wing opens behind the wall to distribute the load. Lag shields expand when a lag bolt is driven into them, offering great vibration resistance. Use these for awnings, large trellises, satellite dishes, and other demanding applications where failure is not an option.

How to Select and Install Stucco Anchors Like a Pro

Proper selection and installation of stucco anchor types are critical for a secure, lasting result. Following the right steps prevents damage and ensures your mounted items stay put.

Choosing the right anchor for your project

Three factors guide your choice of stucco anchor types:

- Object Weight: Consider the total weight, including dynamic loads (e.g., a plant hanger with a watered plant). When in doubt, choose a stronger anchor.

- Substrate Material: What’s behind the stucco? Solid concrete or block works well with sleeve or wedge anchors. For wood studs, you can use a wood screw. For hollow spaces, a toggle bolt is necessary.

- Stucco Type and Thickness: The anchor must be long enough to engage the substrate behind the stucco. Heavily textured stucco may require specific anchors like masonry screws.

Step-by-step installation guide

Follow these steps for a professional installation:

- Mark the spot: Use a pencil and level to mark your drill location accurately.

- Select the drill bit: Use a carbide-tipped masonry bit that matches your anchor’s specified diameter. Using the wrong size will cause the anchor to fail. See our guide on the Best Drill Bit for Stucco.

- Drill the pilot hole: A hammer drill is essential. Hold it perpendicular to the wall and drill to the specified depth without using excessive force. For more details, read How to Drill Into Stucco.

- Clean the hole: Remove all dust and debris with compressed air or a vacuum. A clean hole ensures a proper grip.

- Insert the anchor: Gently tap the anchor into the hole until it is flush with the stucco. Do not force it, as this can crack the wall.

- Set the anchor: Follow the manufacturer’s instructions. This may involve tightening a nut (sleeve anchor) or driving a screw (plastic anchor).

- Fasten the screw: Attach your item and tighten the screw until it is snug. Do not over-tighten, as this can strip the anchor or crack the stucco.

Tools you’ll need

Having the right tools is crucial for success. You will need a hammer drill, a set of masonry drill bits, a level, safety goggles, and a dust mask. Also have compressed air or a vacuum for cleaning holes and a screwdriver or drill/driver. For more on bits, see our Cement Drill Bit guide.

Anchor Maintenance, Removal, and When to Call an Expert

Proper maintenance of stucco anchor types ensures they remain secure and protects your wall. Know how to inspect, remove, and repair anchor points, and when to seek professional help.

Periodic inspection is key, especially for heavy items or exterior anchors. Periodically check for any looseness or wobbling. Look for corrosion signs like rust stains, which indicate the anchor is weakening. Natural thermal cycles can also cause loosening over time.

For anchor removal, patience is crucial to avoid wall damage. To remove plastic anchors, take out the screw and try pulling the anchor with pliers. If it’s stuck, it may be less damaging to push it into the wall and patch over it. Metal expansion anchors are often difficult to remove; the best option may be to cut the head flush with the wall using a grinder or hacksaw and patch over the stub.

To repair holes, use a quality stucco patching compound. Color matching is the biggest challenge, so bring a sample of your stucco to the store if possible. Apply the patch in thin layers and use a sponge or brush to match the existing texture once it’s dry.

When to hire a professional is a critical decision for safety and your home’s value. Always call an expert for heavy loads (awnings, structural elements) or if you have any uncertainty about wall integrity. If you find soft, crumbling material, moisture, or discoloration while drilling, stop immediately. These are signs of potential hidden damage that require a professional inspection.

A certified expert like Stucco Safe can assess for hidden moisture damage. An inspection, which can range from $495 to $1595, is a small investment compared to the cost of repairing widespread water damage. Knowing when not to DIY is a smart decision.

Frequently Asked Questions about Stucco Anchors

Here are answers to common questions about using stucco anchor types.

What is the weight-bearing capacity of different types of stucco anchors?

The capacity depends on the anchor, stucco, and substrate. General guidelines are:

- Light-duty anchors (ribbed plastic, conical): Up to 50 pounds. Ideal for pictures and lightweight decor.

- Medium-duty anchors (sleeve anchors, masonry screws): 50 to 200 pounds. Suitable for mailboxes, shelving, and light fixtures.

- Heavy-duty anchors (wedge anchors): 200 pounds and more. Necessary for awnings, trellises, and structural attachments.

Always check the manufacturer’s specifications on the packaging, as these are the tested limits for that specific product. When in doubt, choose a stronger anchor.

Can stucco anchors cause damage to the wall?

Yes, if installed incorrectly. Damage usually results from a few common mistakes:

- Cracking the stucco: This happens from using the wrong size drill bit, forcing an anchor into a hole, or over-tightening the screw.

- Weak attachment points: An improperly sized hole or the wrong anchor type for the substrate will not grip correctly and will eventually fail.

- Water intrusion: Any crack or unsealed hole can allow water behind the stucco, leading to rot, mold, and structural damage.

To prevent damage, use the correct drilling technique with a hammer drill and masonry bit, as detailed in our guide on the Best Way to Drill Into Stucco. Choose the right anchor for the load and wall type, and tighten screws until they are snug, but do not over-tighten.

How do I know what is behind my stucco wall?

Identifying the substrate behind your stucco is crucial for choosing the right anchor. Here are three methods:

- Use a stud finder: An electronic stud finder can help locate wood or metal studs, though its accuracy can vary through thick stucco.

- Tap the wall: Listen to the sound as you tap with your knuckles. A solid thud suggests concrete or block, while a hollow sound indicates an air gap or lath-and-plaster construction.

- Drill a small test hole: This is the most reliable method. Use a small masonry bit in an inconspicuous spot. Consistent resistance means solid masonry; wood shavings indicate a wood stud or sheathing; an empty space after the stucco means a hollow cavity, which requires a toggle bolt.

Conclusion

Choosing the right stucco anchor types is essential for protecting your home’s integrity. Because stucco is a hard yet brittle material, regular screws will fail and can cause significant damage. Success depends on three key factors: matching the anchor to the load, identifying the substrate behind your wall, and using proper installation techniques.

By selecting the appropriate fastener—from lightweight plastic anchors for decor to heavy-duty wedge anchors for structural loads—you can ensure a secure attachment that prevents cracks and water intrusion.

While many anchor installations are suitable for DIY, it is critical to watch for warning signs. If you find crumbling substrate, moisture, or unexpected softness while drilling, stop immediately. These red flags can indicate serious hidden damage that requires a professional assessment.

At Stucco Safe, our certified inspectors specialize in detecting moisture issues that are not visible to the naked eye. If you are in Southeastern Pennsylvania, New Jersey, or Delaware and have concerns about your stucco’s integrity, we can provide a thorough evaluation.

Investing in the right stucco anchor types and knowing when to call an expert are key to maintaining your home’s value and safety. Learn more about choosing the Best Anchors for Stucco to ensure your next project is a success.